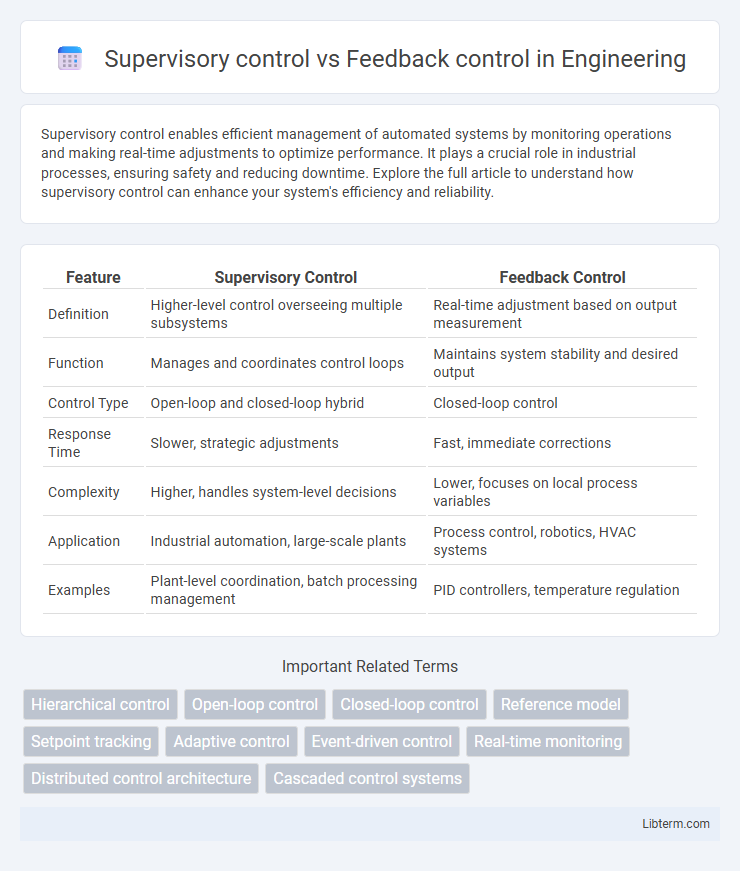

Supervisory control enables efficient management of automated systems by monitoring operations and making real-time adjustments to optimize performance. It plays a crucial role in industrial processes, ensuring safety and reducing downtime. Explore the full article to understand how supervisory control can enhance your system's efficiency and reliability.

Table of Comparison

| Feature | Supervisory Control | Feedback Control |

|---|---|---|

| Definition | Higher-level control overseeing multiple subsystems | Real-time adjustment based on output measurement |

| Function | Manages and coordinates control loops | Maintains system stability and desired output |

| Control Type | Open-loop and closed-loop hybrid | Closed-loop control |

| Response Time | Slower, strategic adjustments | Fast, immediate corrections |

| Complexity | Higher, handles system-level decisions | Lower, focuses on local process variables |

| Application | Industrial automation, large-scale plants | Process control, robotics, HVAC systems |

| Examples | Plant-level coordination, batch processing management | PID controllers, temperature regulation |

Introduction to Control Systems

Supervisory control oversees high-level decision-making by managing multiple feedback control loops and adjusting setpoints based on system goals. Feedback control continuously monitors system outputs to compare them with desired references, automatically correcting deviations to maintain stability and performance. Both control strategies are fundamental components in control systems, enabling efficient, reliable, and adaptive process automation.

Defining Supervisory Control

Supervisory control is a high-level control strategy that manages multiple feedback control loops by making decisions based on overall system objectives and performance criteria. It coordinates and adjusts feedback controllers to optimize system behavior, ensuring efficient and safe operation in complex, dynamic environments. Unlike direct feedback control, which reacts to immediate errors, supervisory control provides strategic oversight and adaptation through monitoring and decision-making processes.

Understanding Feedback Control

Feedback control maintains system stability by continuously monitoring output variables and adjusting inputs to minimize errors between desired and actual performance. It uses sensors to measure real-time data, allowing dynamic corrections that counteract disturbances and uncertainties. This control strategy is essential for processes requiring consistent precision and adaptability, such as temperature regulation, speed control, and automated manufacturing systems.

Core Principles of Supervisory Control

Supervisory control centers on high-level decision-making by monitoring and adjusting the overall system based on performance data, emphasizing hierarchical structure and real-time supervision. It operates by setting reference commands for lower-level controllers, which execute detailed control tasks, ensuring adaptability and fault tolerance in complex systems. This approach contrasts with feedback control, which directly corrects errors by continuously comparing output to desired setpoints within localized control loops.

Key Mechanisms in Feedback Control

Feedback control relies on continuous monitoring of system output to compare actual performance against the desired setpoint, enabling automatic adjustments to minimize error. Key mechanisms include sensors for real-time data acquisition, controllers that process the error signal, and actuators that implement corrective actions. Supervisory control, in contrast, oversees broader system operations without direct involvement in the immediate error correction loop, often coordinating multiple feedback control loops for complex process management.

Supervisory vs Feedback Control: Fundamental Differences

Supervisory control operates at a higher hierarchical level, managing multiple feedback control loops by setting reference inputs and monitoring overall system performance. Feedback control directly regulates a process variable by continuously comparing it to a setpoint and adjusting actuators to minimize error in real time. The fundamental difference lies in supervisory control's role in coordinating complex subsystems, while feedback control provides immediate, localized corrections to maintain stability and desired output.

Applications of Supervisory Control Systems

Supervisory control systems are widely used in industrial automation to coordinate multiple control loops and optimize overall plant performance, such as in chemical processing, power generation, and manufacturing lines. These systems enable high-level decision-making, fault diagnosis, and adaptive control by monitoring lower-level feedback control loops. Applications include energy management in smart grids, automated railway systems, and large-scale HVAC systems where centralized coordination is critical for efficiency and safety.

Applications of Feedback Control Systems

Feedback control systems are extensively applied in industrial automation, maintaining process variables such as temperature, pressure, and flow rate within desired limits to ensure product quality and safety. In automotive engineering, feedback control enhances stability and performance through systems like cruise control and anti-lock braking systems (ABS). Robotics also employs feedback control for precise motion control and adaptive behavior, improving accuracy and responsiveness in dynamic environments.

Advantages and Limitations of Each Approach

Supervisory control excels in managing complex systems by providing high-level decision-making and coordinating multiple feedback control loops, enhancing overall system adaptability and efficiency. Feedback control offers precise regulation of system variables in real-time, ensuring stability and robustness against disturbances but may struggle with system-wide optimization. Supervisory control's limitation lies in its complexity and computational overhead, while feedback control can be limited by its localized scope and slower adaptation to changing global system conditions.

Choosing the Right Control Strategy

Selecting the appropriate control strategy depends on system complexity and performance requirements; supervisory control excels in managing multiple subsystems through high-level decision-making, while feedback control provides real-time error correction in single-loop systems. Supervisory control is optimal for large-scale, hierarchical processes such as manufacturing plants or power grids, leveraging model-based algorithms for adaptive adjustments. Feedback control suits dynamic environments requiring immediate response, utilizing sensors and actuators to minimize deviations from setpoints effectively.

Supervisory control Infographic

libterm.com

libterm.com