What-if analysis is a powerful decision-making tool that helps you explore different scenarios by changing variables to predict possible outcomes. It enables businesses and individuals to evaluate risks, forecast results, and make informed choices based on potential impacts. Discover how applying what-if analysis can improve your strategic planning by reading the rest of the article.

Table of Comparison

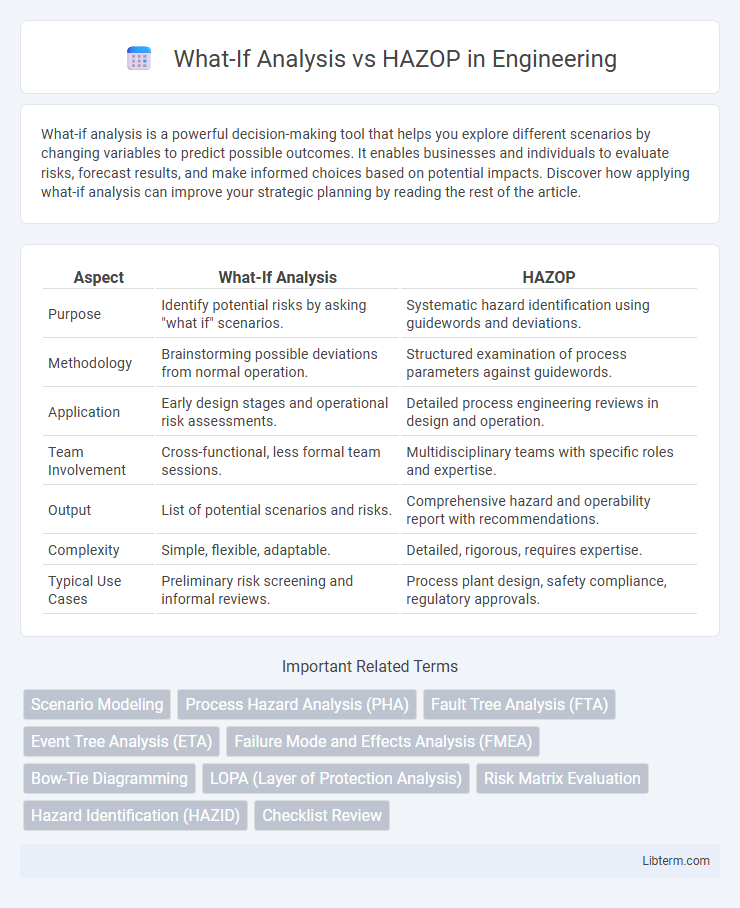

| Aspect | What-If Analysis | HAZOP |

|---|---|---|

| Purpose | Identify potential risks by asking "what if" scenarios. | Systematic hazard identification using guidewords and deviations. |

| Methodology | Brainstorming possible deviations from normal operation. | Structured examination of process parameters against guidewords. |

| Application | Early design stages and operational risk assessments. | Detailed process engineering reviews in design and operation. |

| Team Involvement | Cross-functional, less formal team sessions. | Multidisciplinary teams with specific roles and expertise. |

| Output | List of potential scenarios and risks. | Comprehensive hazard and operability report with recommendations. |

| Complexity | Simple, flexible, adaptable. | Detailed, rigorous, requires expertise. |

| Typical Use Cases | Preliminary risk screening and informal reviews. | Process plant design, safety compliance, regulatory approvals. |

Introduction to What-If Analysis and HAZOP

What-If Analysis systematically explores potential deviations by asking "what if" questions to identify hazards and operational risks during various process stages. HAZOP (Hazard and Operability Study) employs a structured methodology using guide words to examine process deviations and their causes, with the goal of enhancing safety and operability in chemical, manufacturing, and engineering industries. Both techniques are essential in risk assessment, with What-If Analysis offering broader scenario exploration and HAZOP providing detailed, focused examination of process conditions.

Definition and Purpose of What-If Analysis

What-If Analysis is a systematic risk assessment technique used to identify potential hazards by asking hypothetical questions about what could go wrong in a process or system. Unlike HAZOP (Hazard and Operability Study), which focuses on deviations from design intent through structured brainstorming with guide words, What-If Analysis emphasizes exploring possible scenarios to improve safety and operational reliability. The primary purpose of What-If Analysis is to proactively detect vulnerabilities and implement preventive measures before incidents occur.

Definition and Purpose of HAZOP

HAZOP (Hazard and Operability Study) is a systematic, qualitative risk assessment method used to identify potential hazards and operational issues in industrial processes by examining deviations from design intent. Its purpose is to enhance safety and reliability by analyzing process parameters through structured brainstorming sessions, often involving multidisciplinary teams. In contrast, What-If Analysis is a broader, less structured approach that explores hypothetical scenarios to assess possible risks and outcomes without the detailed procedural framework characteristic of HAZOP.

Key Differences Between What-If Analysis and HAZOP

What-If Analysis identifies potential deviations by brainstorming hypothetical scenarios without strict procedural guidance, making it flexible for various industries. HAZOP (Hazard and Operability Study) employs a systematic, structured approach using guide words to analyze process deviations, primarily in chemical and process industries. Key differences include What-If Analysis's open-ended scenario exploration versus HAZOP's detailed, rule-based examination, with HAZOP typically requiring multidisciplinary teams and formal documentation.

Methodology of What-If Analysis

What-If Analysis employs a systematic brainstorming approach to identify potential hazards by posing hypothetical scenarios and evaluating their consequences and causes. This method prioritizes flexibility and simplicity, enabling teams to assess a wide range of deviations without requiring extensive formal procedures or detailed process knowledge. Unlike HAZOP, which follows a structured guide word framework, What-If Analysis promotes creative exploration of potential risks through open-ended questioning and expert judgment.

Methodology of HAZOP

HAZOP (Hazard and Operability Study) employs a systematic, structured methodology involving multidisciplinary teams to identify potential hazards through guide words applied to process parameters, ensuring thorough risk assessment of operational deviations. Unlike What-If Analysis, which is more flexible and exploratory, HAZOP follows a predefined, rigorous procedure with detailed node-by-node examination of process elements to uncover deviations from design intent. This method enhances the detection of process vulnerabilities and operability issues by focusing on causes, consequences, safeguards, and recommendations within each process segment.

Advantages and Limitations of What-If Analysis

What-If Analysis offers a flexible and straightforward approach for identifying potential hazards by asking "what if" scenarios, making it highly adaptable for early-stage risk assessments and diverse operational contexts. Its primary advantage lies in its simplicity and cost-effectiveness, allowing teams to quickly generate a broad range of risk scenarios without requiring extensive technical expertise or complex data. However, What-If Analysis is limited by its reliance on the expertise of participants, potential for overlooking less obvious hazards, and reduced effectiveness in highly complex or technical processes compared to the structured and detailed HAZOP methodology.

Advantages and Limitations of HAZOP

HAZOP (Hazard and Operability Study) provides a systematic, team-based approach to identifying potential hazards and operability problems in complex processes, offering detailed insights into deviations from design intent through guide words and structured brainstorming. Its advantages include thorough hazard identification, fostering multidisciplinary collaboration, and supporting risk mitigation early in the design phase. Limitations of HAZOP involve its time-consuming nature, dependence on experienced facilitators, and potential for overlooking rare or unforeseen failure modes outside the predefined guide word framework.

When to Use What-If Analysis vs HAZOP

What-If Analysis is best used during the early stages of project planning to identify potential risks by exploring hypothetical scenarios in a flexible and less structured manner. HAZOP (Hazard and Operability Study) is more suitable for detailed, systematic examination of complex processes and systems to detect deviations and hazards, especially in chemical, industrial, and manufacturing sectors. Use What-If Analysis when seeking broad risk identification with fewer resources and HAZOP when precise, thorough hazard analysis is critical for safety and compliance.

Conclusion: Choosing the Right Approach for Process Safety

What-If Analysis offers a broad, flexible approach ideal for early-phase hazard identification and brainstorming potential process failures. HAZOP provides a systematic, detailed examination focused on process deviations, ideal for complex systems requiring in-depth risk evaluation. Selecting the right approach depends on the project stage, system complexity, and the level of detail needed for optimal process safety management.

What-If Analysis Infographic

libterm.com

libterm.com