Surface hardness measures a material's resistance to deformation, wear, or scratching, critical for durability in manufacturing and engineering applications. Different testing methods like Rockwell, Brinell, and Vickers provide precise hardness values tailored to specific material types and uses. Explore the full article to understand how surface hardness impacts your projects and product performance.

Table of Comparison

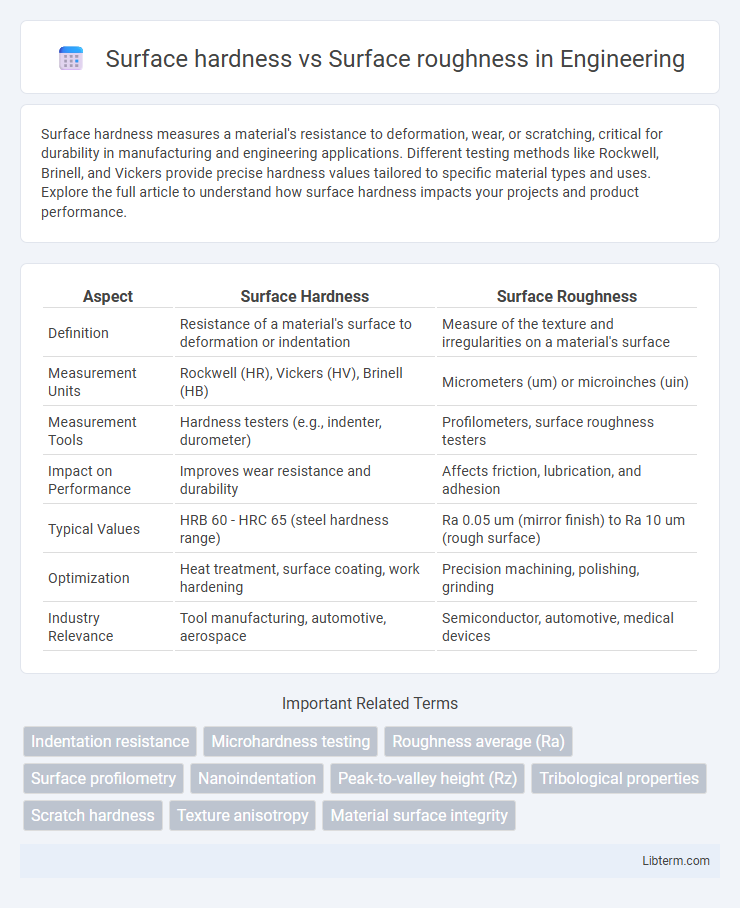

| Aspect | Surface Hardness | Surface Roughness |

|---|---|---|

| Definition | Resistance of a material's surface to deformation or indentation | Measure of the texture and irregularities on a material's surface |

| Measurement Units | Rockwell (HR), Vickers (HV), Brinell (HB) | Micrometers (um) or microinches (uin) |

| Measurement Tools | Hardness testers (e.g., indenter, durometer) | Profilometers, surface roughness testers |

| Impact on Performance | Improves wear resistance and durability | Affects friction, lubrication, and adhesion |

| Typical Values | HRB 60 - HRC 65 (steel hardness range) | Ra 0.05 um (mirror finish) to Ra 10 um (rough surface) |

| Optimization | Heat treatment, surface coating, work hardening | Precision machining, polishing, grinding |

| Industry Relevance | Tool manufacturing, automotive, aerospace | Semiconductor, automotive, medical devices |

Introduction to Surface Hardness and Surface Roughness

Surface hardness quantifies a material's resistance to deformation or indentation, typically measured by methods such as Rockwell, Vickers, or Brinell hardness tests, which reflect the material's wear resistance and durability. Surface roughness describes the texture of a material's surface, characterized by parameters like Ra (average roughness) and Rz (mean peak-to-valley height), influencing friction, adhesion, and appearance. Both surface hardness and surface roughness critically affect a component's performance, especially in mechanical engineering, metallurgy, and manufacturing processes.

Defining Surface Hardness

Surface hardness measures a material's resistance to indentation, abrasion, or deformation, providing critical insight into durability and wear resistance. It is quantified by standardized tests such as Rockwell, Vickers, and Brinell hardness scales, which assess the depth or size of an indentation from a specific force applied by indenter tools. Surface roughness, on the other hand, describes the micro-scale texture of a surface, influencing friction and adhesion, but does not indicate the material's intrinsic resistance to mechanical stress like surface hardness does.

Understanding Surface Roughness

Surface roughness refers to the finer irregularities on a material's surface, measured by parameters like Ra (average roughness) and Rz (mean peak-to-valley height), which directly influence functional properties such as friction, wear, and adhesion. Understanding surface roughness is essential for optimizing manufacturing processes, as it affects coatings, lubrication, and component lifespan more significantly than surface hardness in many applications. Precise characterization of surface roughness enables improved control over mechanical performance and quality assurance in industries like aerospace, automotive, and electronics.

Key Differences Between Surface Hardness and Roughness

Surface hardness measures a material's resistance to indentation or deformation, typically quantified by scales such as Rockwell, Vickers, or Brinell hardness tests. Surface roughness quantifies the texture of a surface, represented by parameters like Ra (average roughness) and Rz (mean peak-to-valley height), indicating microscopic deviations on the surface profile. Key differences include hardness focusing on mechanical strength and durability, while roughness relates to surface topography affecting friction, wear, and aesthetic quality.

Measurement Techniques for Surface Hardness

Measurement techniques for surface hardness primarily include methods such as the Brinell, Rockwell, and Vickers hardness tests, each designed to quantify resistance to indentation under specific loads and indenter shapes. These techniques utilize precise instruments like hardness testers equipped with steel balls or diamond cones to create indentations, with the resulting impression size or depth providing quantitative hardness values. Compared to surface roughness measurements, which involve profilometers or atomic force microscopes to assess texture and irregularities, hardness testing focuses on material strength and wear resistance rather than topographical features.

Methods for Evaluating Surface Roughness

Surface roughness is commonly evaluated using contact profilometers that trace the surface with a diamond-tipped stylus, measuring deviations to quantify roughness parameters such as Ra and Rz. Non-contact optical methods like laser scanning confocal microscopy and white light interferometry provide high-resolution, three-dimensional surface topography without damaging the specimen. These methods yield precise, repeatable measurements crucial for understanding the correlation between surface roughness and functional properties, whereas surface hardness is typically assessed using microhardness testers based on indentation resistance.

Factors Influencing Surface Hardness and Roughness

Surface hardness depends on material composition, heat treatment processes, and cooling rates, significantly affecting wear resistance and durability. Surface roughness is influenced by machining parameters like cutting speed, feed rate, tool geometry, and environmental conditions during manufacturing. Both surface hardness and roughness critically determine the functional performance and lifespan of mechanical components.

Role of Surface Hardness in Material Performance

Surface hardness directly influences wear resistance and durability of a material by resisting deformation under mechanical stress, which ensures longer lifespan in applications exposed to friction or impact. Harder surfaces minimize abrasion, reducing surface roughness changes over time and maintaining dimensional stability critical in precision engineering. Enhanced surface hardness also improves corrosion resistance by limiting micro-scratches that could serve as initiation points for chemical degradation.

Impact of Surface Roughness on Functional Properties

Surface roughness significantly influences functional properties by affecting friction, wear resistance, and fatigue strength of materials. A higher surface roughness can lead to increased abrasion and faster material degradation, while a smoother surface enhances durability and performance in mechanical components. Optimizing surface roughness is critical in industries like aerospace and automotive to ensure reliability and longevity of parts under operational stresses.

Applications and Industries Affecting Surface Quality

Surface hardness and surface roughness critically influence manufacturing industries like aerospace, automotive, and electronics, where material durability and precision are paramount. Hard surfaces improve wear resistance, extending component lifespan in high-stress applications such as turbine blades and engine parts, while low surface roughness ensures optimal aerodynamic and frictional performance. Precision machining, tool manufacturing, and semiconductor production rely on controlling these properties to meet strict quality standards and enhance product functionality.

Surface hardness Infographic

libterm.com

libterm.com