Flash welding is a thermoelectric process that joins metals by generating heat through electrical resistance and applying pressure to fuse the materials without melting them. This method creates strong, durable joints ideal for manufacturing automotive parts, rail components, and structural elements. Explore the rest of the article to understand how flash welding can optimize Your metal joining applications.

Table of Comparison

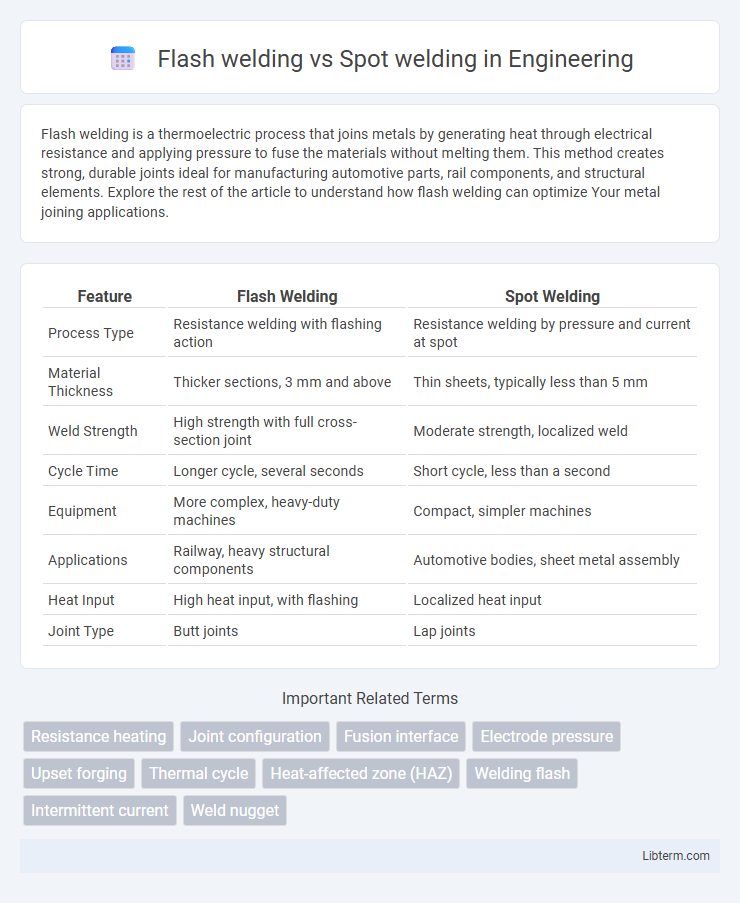

| Feature | Flash Welding | Spot Welding |

|---|---|---|

| Process Type | Resistance welding with flashing action | Resistance welding by pressure and current at spot |

| Material Thickness | Thicker sections, 3 mm and above | Thin sheets, typically less than 5 mm |

| Weld Strength | High strength with full cross-section joint | Moderate strength, localized weld |

| Cycle Time | Longer cycle, several seconds | Short cycle, less than a second |

| Equipment | More complex, heavy-duty machines | Compact, simpler machines |

| Applications | Railway, heavy structural components | Automotive bodies, sheet metal assembly |

| Heat Input | High heat input, with flashing | Localized heat input |

| Joint Type | Butt joints | Lap joints |

Introduction to Flash Welding and Spot Welding

Flash welding is a resistance welding process where an electric current generates heat through an arc to join metal components by flashing the surfaces together under pressure. Spot welding utilizes electrical resistance and pressure to fuse overlapping metal sheets at discrete points without melting the entire interface. Both techniques are essential in automotive and manufacturing industries for creating strong, efficient joints in metal assemblies.

Definition and Process of Flash Welding

Flash welding is a resistance welding process where an electric current generates heat through resistance at the interface of two metal pieces, causing molten metal to form and create a strong joint upon application of pressure. The process begins by clamping the workpieces, then passing a high current to initiate flashing at the gap, which cleans and heats the surfaces by melting the workpiece edges. Once the proper temperature and flash length are achieved, mechanical force forges the pieces together, producing a homogenous weld without filler material or external heat source.

Overview of Spot Welding Techniques

Spot welding techniques utilize electric resistance to join metal sheets by applying pressure and passing current through overlapping metal surfaces, creating localized heat that fuses the materials. This method excels in automotive and manufacturing industries for its speed, efficiency, and minimal thermal distortion. Variations such as projection spot welding and capacitor discharge spot welding enhance precision and control in specific applications.

Key Differences Between Flash Welding and Spot Welding

Flash welding uses an electric arc to generate heat for joining metals, creating a continuous, strong weld along the entire joint, whereas spot welding applies pressure and electric current at specific points to fuse metals. Flash welding is ideal for joining larger, irregular shapes and produces a high-strength, seamless bond, while spot welding is suitable for thin sheets and rapid joint production with discrete weld spots. The key differences lie in the heating method, weld continuity, joint configuration, and application scale.

Applications of Flash Welding in Industry

Flash welding is extensively used in industries requiring strong, continuous joints, such as rail manufacturing, automotive axle production, and aerospace component assembly. Its ability to join large or irregularly shaped metal parts makes it ideal for heavy machinery, structural steel, and pipe manufacturing. Compared to spot welding, flash welding delivers superior tensile strength and durability for load-bearing applications.

Common Uses of Spot Welding

Spot welding is commonly used in automotive manufacturing for joining sheet metal parts quickly and efficiently, ensuring strong and reliable seams. It is also widely employed in battery pack assembly and appliance production due to its precision and ability to join thin metal sheets without distortion. This weld type is ideal for high-volume production environments requiring fast, repeatable, and cost-effective metal joining.

Strengths and Weaknesses: Flash Welding vs Spot Welding

Flash welding offers high joint strength and excellent fatigue resistance due to its continuous metal fusion process, making it ideal for heavy-duty applications and complex geometries. Spot welding provides rapid, cost-effective joining of thin materials with minimal heat distortion but tends to create weaker joints susceptible to stress concentration and limited load-bearing capacity. The primary trade-off lies in flash welding's longer cycle time and higher equipment cost versus spot welding's faster production speed and lower initial investment.

Material Suitability for Each Welding Method

Flash welding is ideal for joining ferrous metals such as steel and iron, offering excellent strength and minimal distortion for components like rails and rods. Spot welding suits thin sheet metals, particularly low-carbon steel and stainless steel, making it common in automotive body assembly and appliances. Materials with high electrical conductivity, like aluminum, pose challenges for flash welding but can be effectively joined using spot welding with proper electrode control.

Cost and Efficiency Comparison

Flash welding offers higher efficiency in joining large components due to its faster cycle times and minimal material waste, making it cost-effective for heavy-duty industrial applications. Spot welding, while generally less expensive in terms of equipment and setup, excels in high-volume production settings with thinner materials, providing quick and consistent welds that reduce labor costs. Overall, flash welding incurs higher initial costs but delivers long-term savings through enhanced strength and durability, whereas spot welding remains a budget-friendly choice for rapid, less-intensive assembly tasks.

Conclusion: Choosing the Right Welding Method

Choosing between flash welding and spot welding depends on the specific application requirements, such as material thickness, joint strength, and production volume. Flash welding offers superior strength and is ideal for joining dissimilar metals or larger components, while spot welding excels in high-speed production for thin sheets and provides efficient, localized heat. Evaluating factors like cost, weld quality, and equipment availability ensures optimal selection for industrial manufacturing processes.

Flash welding Infographic

libterm.com

libterm.com