Bolted joints provide a reliable method for assembling components by using threaded fasteners that create clamping force through tension. This type of joint is crucial in various industries due to its ease of installation, disassembly, and ability to withstand significant mechanical loads. Discover how bolted joints enhance the integrity of your structures by reading the full article.

Table of Comparison

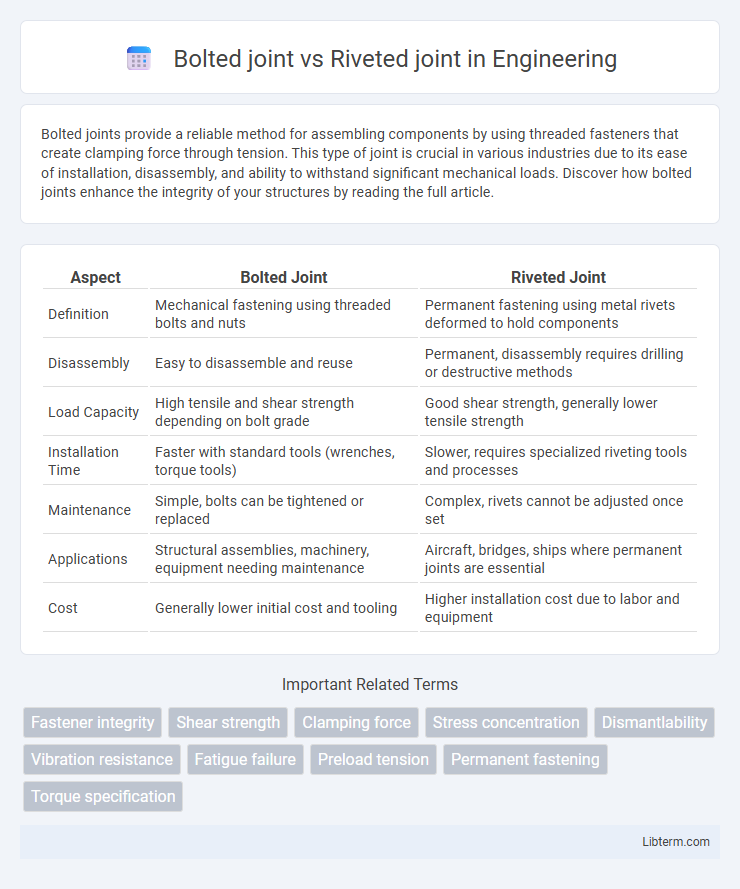

| Aspect | Bolted Joint | Riveted Joint |

|---|---|---|

| Definition | Mechanical fastening using threaded bolts and nuts | Permanent fastening using metal rivets deformed to hold components |

| Disassembly | Easy to disassemble and reuse | Permanent, disassembly requires drilling or destructive methods |

| Load Capacity | High tensile and shear strength depending on bolt grade | Good shear strength, generally lower tensile strength |

| Installation Time | Faster with standard tools (wrenches, torque tools) | Slower, requires specialized riveting tools and processes |

| Maintenance | Simple, bolts can be tightened or replaced | Complex, rivets cannot be adjusted once set |

| Applications | Structural assemblies, machinery, equipment needing maintenance | Aircraft, bridges, ships where permanent joints are essential |

| Cost | Generally lower initial cost and tooling | Higher installation cost due to labor and equipment |

Introduction to Mechanical Joints

Bolted joints offer high tensile strength and ease of assembly, making them ideal for applications requiring frequent disassembly and maintenance. Riveted joints provide permanent fastening with excellent shear strength, commonly used in structural aerospace and bridge construction. The choice between bolted and riveted joints depends on factors such as load conditions, accessibility, and the need for joint inspection or replacement.

Overview of Bolted Joints

Bolted joints utilize threaded fasteners to connect components, offering easy assembly and disassembly for maintenance and inspection. These joints provide adjustable clamping force, making them suitable for applications requiring precise tension control and vibration resistance. Commonly used in automotive, aerospace, and structural engineering, bolted joints accommodate various materials and thicknesses with standardized torque specifications.

Overview of Riveted Joints

Riveted joints consist of multiple metal components fastened together using rivets, which are permanent mechanical fasteners formed by deforming the rivet body to create a strong interlock. They are commonly used in structural applications such as bridges, aircraft, and pressure vessels due to their high strength and resistance to fatigue and shear forces. Compared to bolted joints, riveted joints provide superior vibration resistance and do not loosen over time, making them ideal for dynamic or heavy-load conditions.

Design and Construction Differences

Bolted joints use threaded fasteners and nuts, allowing for easy assembly, disassembly, and adjustment, whereas riveted joints employ permanent metal pins deformed to hold materials together, resulting in a fixed and robust connection. In design, bolted joints require precise hole alignment and torque specifications to maintain clamping force, while riveted joints depend on proper rivet size and deformation techniques for strength and fatigue resistance. Construction of bolted joints involves straightforward tightening of bolts, facilitating maintenance, whereas riveted joints require specialized tools and processes such as heating or hydraulic pressing to install and achieve a secure bond.

Strength and Load-Bearing Capabilities

Bolted joints offer superior strength and high load-bearing capabilities due to their ability to generate clamping force and resist shear and tensile loads effectively. Riveted joints provide good load distribution and vibration resistance but typically have lower tensile strength compared to bolted joints. In applications requiring frequent disassembly or higher load tolerance, bolted joints are preferred for their reliability and ease of maintenance.

Installation and Assembly Processes

Bolted joint installation involves aligning components and tightening bolts using torque wrenches to achieve precise clamping force, enabling easy disassembly and maintenance. Riveted joint assembly requires heating or cold-driving rivets into pre-drilled holes, creating a permanent fastening that demands specialized tools and skilled labor. Bolted joints offer faster, adjustable assembly, whereas riveted joints provide durable, vibration-resistant connections ideal for high-stress applications.

Maintenance and Inspectability

Bolted joints offer superior maintenance and inspectability due to their ease of disassembly and reassembly, allowing for quick inspections and repairs without damaging components. Riveted joints are generally permanent, requiring destructive methods or specialized non-destructive testing techniques, such as ultrasonic or radiographic inspection, which complicates maintenance and prolongs downtime. The ability to reuse bolted joints enhances cost efficiency and reduces operational interruptions compared to riveted joints.

Applications and Industry Usage

Bolted joints are extensively used in automotive, aerospace, and heavy machinery industries for their ease of assembly, disassembly, and maintenance in applications requiring high strength and precision. Riveted joints find primary usage in aircraft manufacturing, bridge construction, and shipbuilding, where permanent, vibration-resistant connections are critical. The preference for bolted joints in modular structures contrasts with riveted joints' dominance in safety-critical, load-distributing applications due to their reliable shear strength and fatigue resistance.

Cost Comparison: Bolted vs Riveted Joints

Bolted joints generally offer lower initial costs compared to riveted joints due to simpler installation processes and reduced labor requirements. Riveted joints, while historically favored for their strength and reliability, involve higher expenses related to specialized equipment and longer assembly times. Maintenance costs for bolted joints tend to be lower as they allow easier disassembly and reassembly, improving overall cost efficiency in construction and machinery applications.

Choosing the Right Joint for Your Project

Bolted joints offer easy disassembly and superior tensile strength making them ideal for projects requiring maintenance or adjustments, while riveted joints provide permanent and vibration-resistant connections suited for high-stress, dynamic applications. Selection depends on factors such as load type, accessibility, environmental conditions, and the necessity for future joint removal. Evaluating these parameters ensures optimal joint performance and structural integrity.

Bolted joint Infographic

libterm.com

libterm.com