Countersinking creates a conical hole that allows screws or bolts to sit flush with or below a surface, improving both aesthetics and functionality. This technique is essential in woodworking, metalworking, and manufacturing to ensure secure fastening without protruding fasteners. Explore the rest of this article to learn the precise methods and tools you can use for effective countersinking.

Table of Comparison

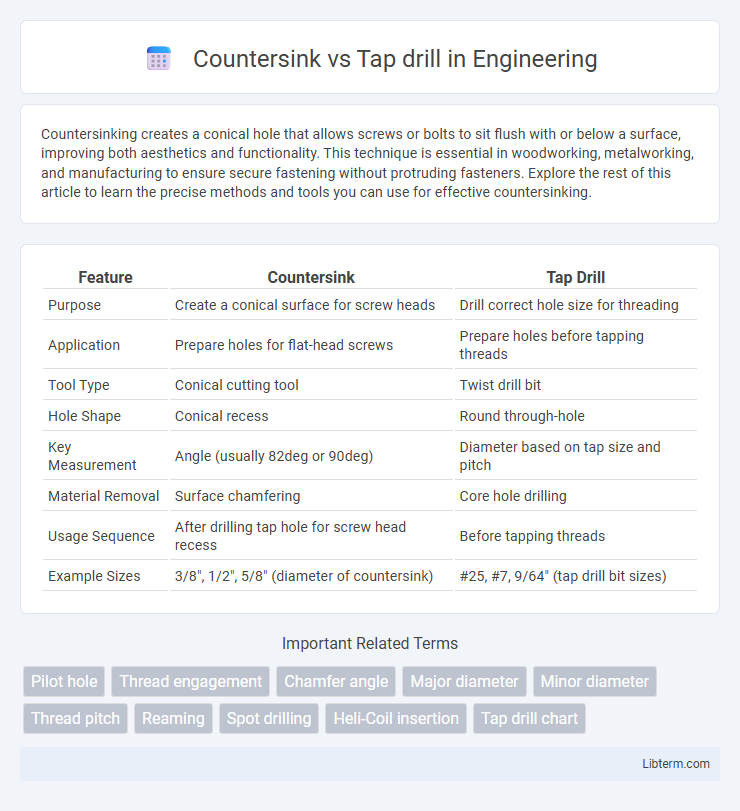

| Feature | Countersink | Tap Drill |

|---|---|---|

| Purpose | Create a conical surface for screw heads | Drill correct hole size for threading |

| Application | Prepare holes for flat-head screws | Prepare holes before tapping threads |

| Tool Type | Conical cutting tool | Twist drill bit |

| Hole Shape | Conical recess | Round through-hole |

| Key Measurement | Angle (usually 82deg or 90deg) | Diameter based on tap size and pitch |

| Material Removal | Surface chamfering | Core hole drilling |

| Usage Sequence | After drilling tap hole for screw head recess | Before tapping threads |

| Example Sizes | 3/8", 1/2", 5/8" (diameter of countersink) | #25, #7, 9/64" (tap drill bit sizes) |

Introduction to Countersink and Tap Drill

Countersink and tap drill are essential tools in metalworking and machining, each serving distinct purposes in hole preparation. A countersink creates a conical recess around a hole to allow screw heads to sit flush with or below the surface, enhancing aesthetic and functional finishes. Tap drill size is critical for threading, as it determines the hole diameter that enables proper thread formation for fasteners such as bolts and screws.

Understanding Countersink: Definition and Purpose

Countersink is a conical hole cut into a material to allow the head of a countersunk screw or bolt to sit flush with or below the surface. Its purpose is to provide a smooth, finished appearance while preventing damage or obstruction caused by protruding fastener heads. Understanding the correct countersink angle and diameter ensures proper fit and alignment in assembly tasks compared to tap drill, which focuses on creating threads for screws.

What is a Tap Drill? Key Concepts

A tap drill is the hole diameter drilled before tapping threads into a material, ensuring proper thread engagement and strength. Selecting the correct tap drill size depends on the thread pitch and material type for optimal cutting and tool longevity. Unlike countersinks, which create a conical recess for screw heads, tap drills prepare precise holes for internal threads.

Design Differences: Countersink vs Tap Drill

Countersink and tap drill differ significantly in design and function; countersinks create a conical recess to allow screw heads to sit flush with or below the surface, typically designed with a specific angle matching the screw head, commonly 82deg or 90deg. Tap drills are engineered to create a precise hole diameter slightly smaller than the screw's major diameter, allowing threads to be cut effectively during tapping; the drill size is calculated based on the thread pitch to ensure optimal thread engagement. While countersinks focus on surface finish and screw head alignment, tap drills prioritize thread integrity and fit within the material.

Common Applications of Countersink and Tap Drill

Countersinks are commonly used in woodworking and metalworking to create conical holes that allow screw heads to sit flush with or below the surface of the material, ideal for aesthetic finishes and preventing snagging. Tap drills are primarily applied in threading operations for preparing holes the correct size before tapping, ensuring precise internal threads in materials such as metals, plastics, and composites. Both countersink and tap drills are essential in manufacturing, automotive, and construction industries where fastening and assembly integrity are critical.

Choosing the Right Tool: Factors to Consider

Choosing the right tool between countersink and tap drill depends on the specific machining requirements and material type. Countersinks create a conical surface for screw heads to sit flush, ideal for finishing and aesthetic purposes, while tap drills prepare holes for threading by removing precise material volume to ensure proper thread engagement. Factors such as hole diameter, thread size, material hardness, and the desired finish quality guide the decision to optimize tool performance and workpiece integrity.

Step-by-Step Countersinking Process

The step-by-step countersinking process begins by selecting the proper countersink drill bit size based on the screw's head diameter and material type. After drilling the pilot hole with the tap drill size appropriate for the screw's thread specifications, the countersink bit is used to create a conical recess that allows the screw head to sit flush or below the surface. This precise method enhances the joint's durability by ensuring proper seating and avoiding material stress or deformation.

How to Perform Tap Drilling Correctly

To perform tap drilling correctly, select a drill bit size that matches the recommended tap drill chart for the specific thread pitch and diameter, ensuring the hole is slightly smaller than the tap's major diameter to allow proper thread formation. Drill the hole perpendicular to the workpiece surface and maintain consistent speed and pressure to avoid misalignment or tool breakage. Countersinking after drilling helps create a chamfered edge, guiding the tap and reducing the risk of thread distortion, which improves the overall quality and durability of the threaded connection.

Pros and Cons: Countersink vs Tap Drill

Countersink drills create a conical hole to allow screw heads to sit flush with or below the surface, enhancing aesthetic appeal and reducing snagging risk; however, they do not form threads, requiring pre-threaded holes or subsequent tapping. Tap drills cut precise threads within a drilled hole, ensuring strong internal threads for screws or bolts, but they need exact sizing to avoid weak joints or damaged threads. Choosing between countersink and tap drills depends on whether the application prioritizes flush screw placement or threaded hole integrity.

Final Comparison and Selection Guide

Countersink drills create a conical recess for screw heads, ensuring flush and clean finishes, while tap drills prepare precise hole diameters for threading. Selecting the correct drill depends on the application: use countersink for surface-mounted screws and tap drills for creating internal threads. Final selection hinges on material type, screw specifications, and desired thread integrity to optimize fastening strength and durability.

Countersink Infographic

libterm.com

libterm.com