Permanent Magnet Synchronous Motors (PMSM) offer high efficiency and precise control, making them ideal for applications requiring smooth torque and high power density. Switched Reluctance Motors (SRM) provide robustness and simplicity, excelling in harsh environments due to their fault-tolerant design and cost-effectiveness. Discover how these motors compare and which one suits your specific needs by exploring the rest of the article.

Table of Comparison

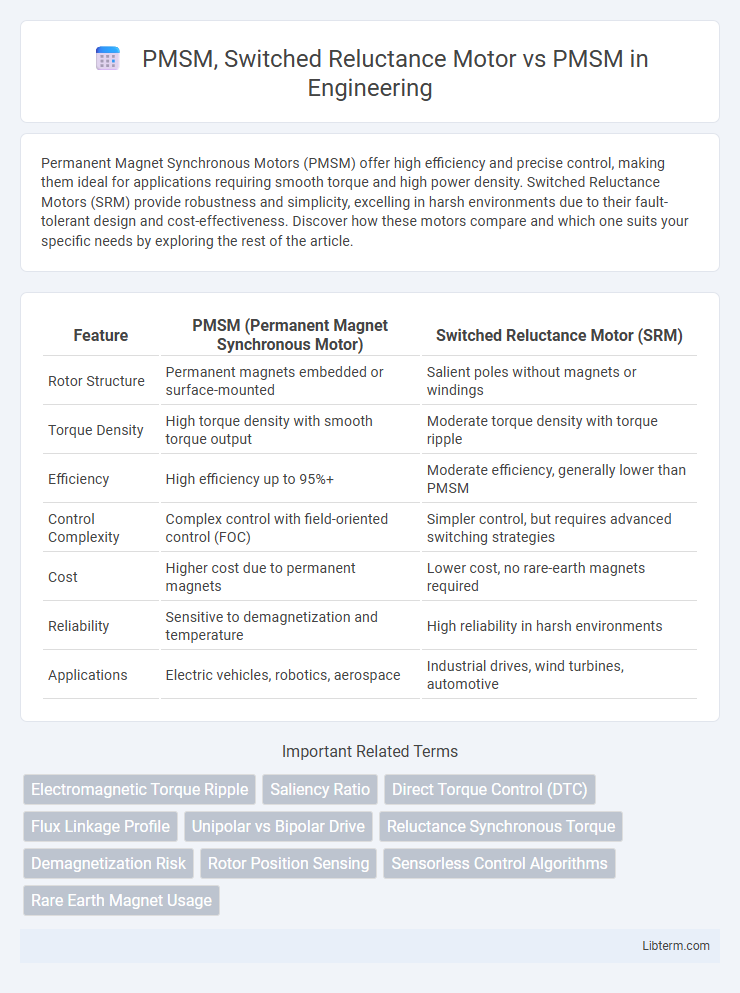

| Feature | PMSM (Permanent Magnet Synchronous Motor) | Switched Reluctance Motor (SRM) |

|---|---|---|

| Rotor Structure | Permanent magnets embedded or surface-mounted | Salient poles without magnets or windings |

| Torque Density | High torque density with smooth torque output | Moderate torque density with torque ripple |

| Efficiency | High efficiency up to 95%+ | Moderate efficiency, generally lower than PMSM |

| Control Complexity | Complex control with field-oriented control (FOC) | Simpler control, but requires advanced switching strategies |

| Cost | Higher cost due to permanent magnets | Lower cost, no rare-earth magnets required |

| Reliability | Sensitive to demagnetization and temperature | High reliability in harsh environments |

| Applications | Electric vehicles, robotics, aerospace | Industrial drives, wind turbines, automotive |

Introduction to PMSM and Switched Reluctance Motors

Permanent Magnet Synchronous Motors (PMSMs) utilize permanent magnets embedded on the rotor, enabling high efficiency, precise control, and compact design suitable for electric vehicles and industrial automation. Switched Reluctance Motors (SRMs) operate based on the principle of magnetic reluctance, featuring a simple and robust construction with no permanent magnets, making them cost-effective and tolerant to harsh environments. PMSMs offer smoother torque and higher power density, whereas SRMs excel in reliability and fault tolerance due to their rugged design and lack of permanent magnets.

Fundamentals of Permanent Magnet Synchronous Motor (PMSM)

The Permanent Magnet Synchronous Motor (PMSM) operates using permanent magnets embedded in the rotor, generating a constant magnetic field that interacts with the stator's rotating magnetic field to produce torque with high efficiency and precision. Compared to Switched Reluctance Motors (SRMs), PMSMs offer smoother torque output, higher power density, and better dynamic response due to their sinusoidal back-EMF and continuous rotor magnetization. Fundamental characteristics of PMSMs include synchronized rotor speed with the stator's rotating field, low rotor inertia, and reduced torque ripple, making them ideal for applications requiring precise speed control and high efficiency.

Key Features of Switched Reluctance Motor (SRM)

Switched Reluctance Motors (SRMs) feature a simple and robust rotor design without permanent magnets or windings, resulting in lower manufacturing costs and higher reliability compared to Permanent Magnet Synchronous Motors (PMSMs). SRMs provide high fault tolerance and can operate efficiently over a wide speed range, making them suitable for harsh environments and applications requiring variable speed control. Their torque production relies on the magnetic reluctance difference, which gives SRMs a unique characteristic of producing high starting torque with reduced sensitivity to rotor position estimation errors.

Working Principles: PMSM vs SRM

Permanent Magnet Synchronous Motors (PMSM) operate based on the interaction between permanent magnets on the rotor and a rotating magnetic field generated by the stator, producing smooth torque and high efficiency. Switched Reluctance Motors (SRM) function by sequentially energizing stator windings to create a magnetic field that aligns the rotor's salient poles to minimize reluctance, resulting in torque production through variable magnetic reluctance. PMSM offers continuous torque due to constant magnetic fields, while SRM relies on the alignment of magnetic circuits, leading to distinct operational characteristics and control strategies.

Efficiency Comparison: PMSM vs Switched Reluctance Motor

Permanent Magnet Synchronous Motors (PMSMs) exhibit higher efficiency compared to Switched Reluctance Motors (SRMs) due to their continuous rotor magnetization and smoother torque production, which minimizes energy losses. PMSMs typically achieve efficiencies above 90%, driven by low copper and iron losses, whereas SRMs often show lower efficiency levels due to torque ripple and higher core losses. In electric vehicle and industrial applications, PMSMs are favored for their superior efficiency and performance despite the higher cost and complexity relative to SRMs.

Torque and Performance Characteristics

Permanent Magnet Synchronous Motors (PMSMs) deliver high torque density and smooth performance due to their permanent magnets, providing consistent torque across a wide speed range. Switched Reluctance Motors (SRMs) exhibit robust torque production with simple construction but experience torque ripple and vibration, affecting smoothness. PMSMs excel in applications demanding precise torque control and high efficiency, while SRMs are favored for their durability and cost-effective high-torque output under harsh conditions.

Control Strategies: PMSM and SRM

Permanent Magnet Synchronous Motors (PMSM) utilize vector control strategies such as Field-Oriented Control (FOC) to achieve precise torque and speed regulation through controlling the stator current components. Switched Reluctance Motors (SRM) rely on position-sensor-based current control with emphasis on commutation timing and phase excitation to maximize torque production despite their nonlinear inductance profile. Advanced control algorithms for PMSM focus on minimizing torque ripple and optimizing efficiency, while SRM control strategies prioritize robustness and fault tolerance under variable load conditions.

Application Areas: PMSM vs SRM

Permanent Magnet Synchronous Motors (PMSMs) dominate applications requiring high efficiency and precise control, such as electric vehicles, robotics, and aerospace systems. Switched Reluctance Motors (SRMs) excel in high-speed and high-temperature environments including washing machines, vacuum cleaners, and industrial pumps due to their simple construction and robustness. PMSMs offer superior torque density and smooth operation, while SRMs provide cost-effective performance in rugged applications with less sensitivity to demagnetization.

Advantages and Disadvantages of Each Motor Type

Permanent Magnet Synchronous Motors (PMSM) offer high efficiency, superior torque density, and smooth operation due to their permanent magnets, making them ideal for precision applications and electric vehicles. Switched Reluctance Motors (SRM) excel in robustness, simple mechanical construction, and cost-effectiveness, with good performance in high-speed and high-temperature environments but exhibit higher torque ripple and acoustic noise. PMSMs require rare-earth magnets and complex control algorithms, raising cost and sensitivity to demagnetization, whereas SRMs tolerate harsh conditions and lower manufacturing costs but demand advanced control strategies to mitigate vibration and efficiency losses.

Future Trends and Innovations in Motor Technology

Permanent Magnet Synchronous Motors (PMSMs) continue to advance with innovations in rare-earth magnet materials and high-efficiency inverter technologies, enhancing power density and reducing energy consumption. Compared to Switched Reluctance Motors (SRMs), PMSMs benefit from more precise control algorithms and improved thermal management systems, driving their adoption in electric vehicles and renewable energy applications. Future trends emphasize integrating Artificial Intelligence for predictive maintenance and developing hybrid magnet designs to optimize performance across diverse operational conditions.

PMSM, Switched Reluctance Motor Infographic

libterm.com

libterm.com