Point contact refers to a small, localized area where two conductive materials touch, allowing electrical current to pass with minimal resistance. This concept is critical in electronic devices such as transistors, sensors, and microchips, where precise control over current flow is essential. Explore the rest of the article to understand how point contact influences device performance and your technology applications.

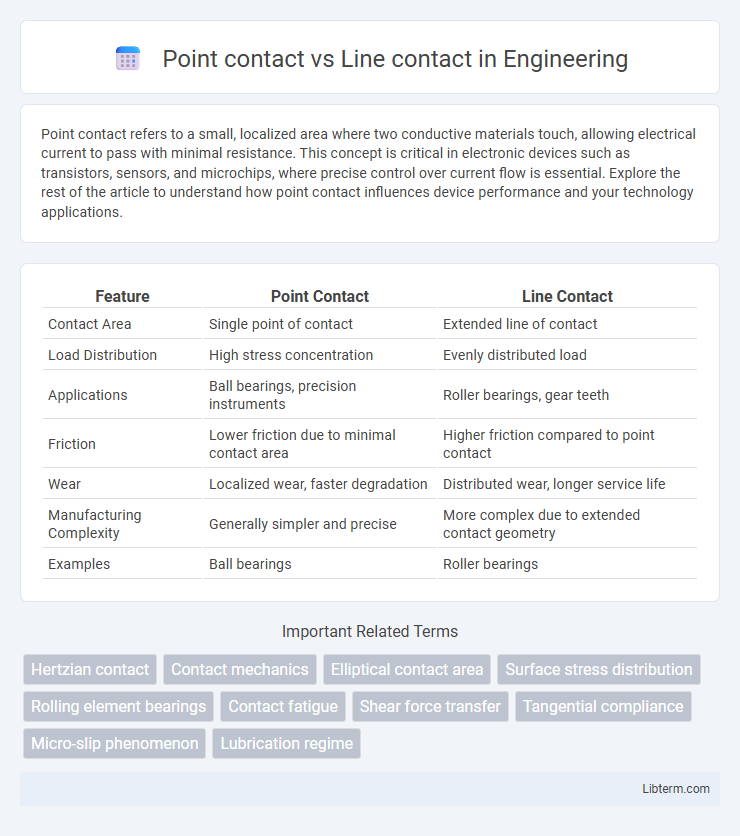

Table of Comparison

| Feature | Point Contact | Line Contact |

|---|---|---|

| Contact Area | Single point of contact | Extended line of contact |

| Load Distribution | High stress concentration | Evenly distributed load |

| Applications | Ball bearings, precision instruments | Roller bearings, gear teeth |

| Friction | Lower friction due to minimal contact area | Higher friction compared to point contact |

| Wear | Localized wear, faster degradation | Distributed wear, longer service life |

| Manufacturing Complexity | Generally simpler and precise | More complex due to extended contact geometry |

| Examples | Ball bearings | Roller bearings |

Introduction to Contact Mechanics

Point contact in contact mechanics occurs when two surfaces touch at a single or very small area, typically seen in ball bearings and Hertzian contacts, resulting in localized stress concentration. Line contact involves two surfaces contacting along a line, common in cylindrical roller bearings, distributing load over a larger area and reducing stress intensity. Understanding these contact types is essential for predicting deformation, stress distribution, and wear in mechanical components under load.

Defining Point Contact

Point contact refers to the interaction between two surfaces where contact occurs at a single, well-defined point, resulting in high contact stress due to the minimal contact area. This type of contact is commonly seen in ball bearings, where spherical elements roll over raceways, concentrating forces on a single point. Understanding the mechanics of point contact is essential for designing components subjected to precise load distribution and minimizing wear under localized stress conditions.

Understanding Line Contact

Line contact occurs when two surfaces meet along a single line rather than at a single point, resulting in increased contact area and improved load distribution. This type of contact is commonly found in cylindrical gears, rolling element bearings, and cam-follower mechanisms, where enhanced stability and reduced wear are critical. Understanding line contact mechanics helps optimize friction, wear resistance, and durability in mechanical components under varying load conditions.

Key Differences: Point vs Line Contact

Point contact involves two curved surfaces touching at a single precise point, resulting in high stress concentration and limited contact area, commonly seen in ball bearings. Line contact occurs when two surfaces meet along a straight line, distributing the load over a larger area and reducing stress concentration, typical in roller bearings. The key difference lies in the contact geometry affecting load distribution, friction, wear characteristics, and bearing life span.

Applications of Point Contact

Point contact technology is widely used in applications requiring precise electrical connections with minimal contact area, such as in microelectromechanical systems (MEMS) and sensor probes. Its small contact interface allows for high sensitivity and reduced mechanical wear, making it ideal for touch sensors, micro-switches, and precision measurement instruments. The localized contact also enhances performance in electronic devices where low resistance and rapid switching are critical.

Applications of Line Contact

Line contact bearings, commonly used in rolling element bearings such as cylindrical and tapered roller types, provide enhanced load-carrying capacity by distributing forces along a line rather than a single point. These bearings are ideal for applications involving heavy radial and axial loads, such as in automotive transmissions, industrial gearboxes, and conveyor systems, where durability and reduced friction are critical. The extended contact area improves wear resistance and heat dissipation, making line contact solutions preferable in high-speed and high-load mechanical assemblies.

Advantages and Disadvantages

Point contact bearings offer lower friction and faster response times due to minimal contact area, making them ideal for high-speed applications; however, they generally have lower load capacity and reduced durability under heavy loads. Line contact bearings distribute the load over a larger surface area, enhancing load-carrying capacity and longevity, but they typically generate higher friction and are less suited for very high-speed operations. Selecting between point contact and line contact depends on the balance between speed requirements and load handling needs in specific mechanical systems.

Real-World Examples

Point contact occurs in ball bearings where spherical elements touch the races at a single point, enabling smooth rotation with minimal friction, common in skateboard wheels and small electric motors. Line contact is found in roller bearings where cylindrical rollers contact the raceway along a line, distributing loads over a greater area and enhancing load-carrying capacity, typical in heavy machinery like conveyor belts and automotive transmissions. The choice between point and line contact directly impacts durability, load support, and friction characteristics in industrial and consumer applications.

Material Considerations and Wear

Point contact in mechanical systems concentrates stress on a small area, leading to higher localized wear and potential surface deformation, especially in harder materials. Line contact distributes load over a longer area, reducing contact stress and enhancing wear resistance, particularly beneficial for materials with lower hardness or toughness. Material selection must account for contact type: ceramics and hardened steels perform well under point contact, whereas ductile metals and composites excel under line contact due to better load distribution.

Choosing the Right Contact Type

Choosing the right contact type depends on load, speed, and application precision requirements; point contact bearings, such as ball bearings, provide minimal friction and are ideal for high-speed, low-load scenarios. Line contact bearings, like cylindrical roller bearings, distribute loads over a larger area, offering higher load capacity and better durability for heavy-duty or high-impact applications. Proper selection enhances equipment performance, reduces wear, and extends service life by aligning bearing characteristics with operational demands.

Point contact Infographic

libterm.com

libterm.com