Spinal Muscular Atrophy (SMA) is a genetic disorder characterized by progressive muscle weakness due to the loss of motor neurons in the spinal cord. Early diagnosis and advanced treatments can significantly improve quality of life and slow disease progression. Discover how understanding SMA can empower your decisions and improve outcomes by reading the full article.

Table of Comparison

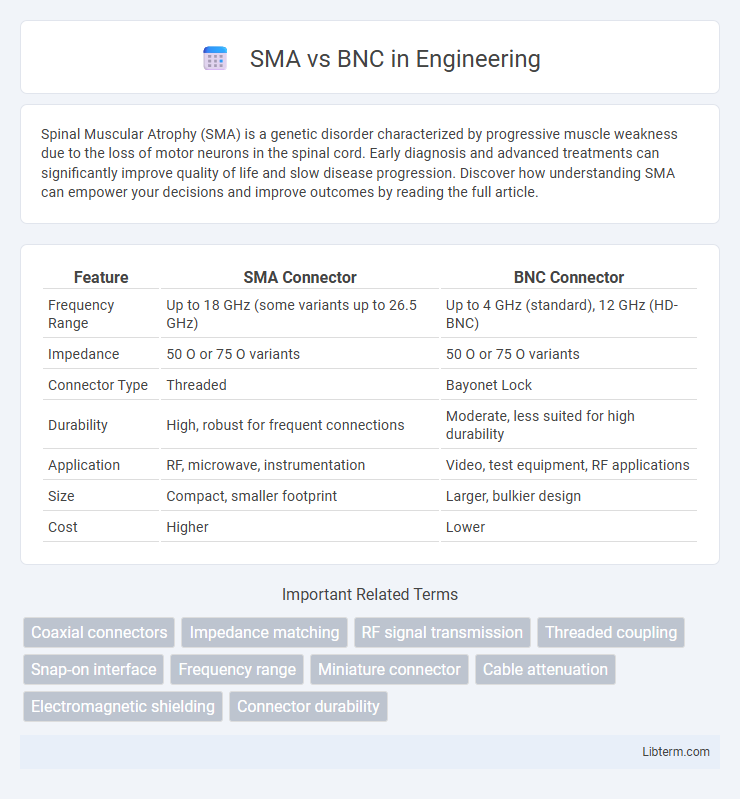

| Feature | SMA Connector | BNC Connector |

|---|---|---|

| Frequency Range | Up to 18 GHz (some variants up to 26.5 GHz) | Up to 4 GHz (standard), 12 GHz (HD-BNC) |

| Impedance | 50 O or 75 O variants | 50 O or 75 O variants |

| Connector Type | Threaded | Bayonet Lock |

| Durability | High, robust for frequent connections | Moderate, less suited for high durability |

| Application | RF, microwave, instrumentation | Video, test equipment, RF applications |

| Size | Compact, smaller footprint | Larger, bulkier design |

| Cost | Higher | Lower |

Overview of SMA and BNC Connectors

SMA connectors feature a threaded interface offering reliable, high-frequency performance up to 18 GHz, commonly used in RF applications and microwave systems for secure connections. BNC connectors utilize a bayonet locking mechanism, supporting frequencies up to 4 GHz, ideal for quick connect/disconnect in video and RF signal applications. Both connectors ensure impedance matching with SMA typically at 50 ohms and BNC available in 50 or 75 ohms, affecting their suitability for different signal transmission environments.

Key Differences Between SMA and BNC

SMA connectors feature a threaded coupling mechanism optimized for high-frequency applications up to 18 GHz, whereas BNC connectors use a bayonet locking system suitable for frequencies up to 4 GHz. SMA connectors provide superior durability and stability, making them ideal for microwave systems, while BNC connectors are commonly used in video and RF signal connections due to their easy connect/disconnect design. The compact size of SMA connectors versus the larger form factor of BNCs also influences their respective use cases in precision instrumentation and broadcast environments.

Physical Design and Construction

SMA connectors feature a threaded coupling mechanism with a compact, cylindrical design primarily constructed from stainless steel or brass with gold or nickel plating, ensuring strong durability and excellent resistance to environmental factors. BNC connectors utilize a bayonet-style coupling system with a larger, more robust cylindrical body made often from nickel-plated brass, designed for quick connect and disconnect operations, providing reliable mechanical stability and consistent impedance. The physical design of SMA connectors supports higher frequency performance up to 18 GHz, while BNC connectors typically operate effectively up to 4 GHz due to their larger size and coupling mechanism.

Frequency Range and Performance

SMA connectors typically operate efficiently within a frequency range of DC to 18 GHz, making them suitable for high-frequency microwave applications, while BNC connectors generally perform well up to 4 GHz, limiting their use to lower-frequency signals. SMA connectors provide superior performance in terms of signal integrity and minimal insertion loss at higher frequencies due to their precision threading and robust design. BNC connectors offer ease of use with quick connect/disconnect capabilities but experience increased signal degradation and reflection beyond their specified frequency range.

Applications in Industry

SMA connectors are widely used in RF and microwave applications due to their superior performance at high frequencies, making them ideal for telecommunications, aerospace, and test equipment. BNC connectors, favored for their quick connect/disconnect capabilities and rugged design, are commonly employed in video transmission, instrumentation, and broadcast industries. Both connector types support reliable signal integrity, but SMA's precision machining suits demanding high-frequency environments, whereas BNC's bayonet coupling excels in applications requiring frequent connection changes.

Ease of Installation and Use

SMA connectors offer straightforward installation with threaded coupling that ensures secure and reliable connections, making them user-friendly for both professionals and enthusiasts. BNC connectors use a bayonet-style locking mechanism that allows quick, tool-free attachment and detachment, ideal for applications requiring frequent connections. While SMA connectors are preferred for high-frequency and precision tasks, BNC connectors excel in ease of use and speed in setups like video and RF signal testing.

Durability and Environmental Resistance

SMA connectors offer superior durability with their threaded coupling mechanism, providing strong resistance to vibration and mechanical stress compared to BNC connectors' bayonet design. SMA connectors maintain excellent environmental resistance, featuring hermetic sealing and superior performance in extreme temperatures, moisture, and UV exposure. BNC connectors are less robust in harsh conditions, making SMA connectors preferable for demanding outdoor and industrial applications where longevity and reliability are critical.

Cost Comparison

SMA connectors generally cost more due to their precision engineering and superior performance at higher frequencies, often ranging from $5 to $20 per piece depending on quality and manufacturer. BNC connectors are typically more affordable, priced between $1 and $5 each, making them a cost-effective choice for lower-frequency applications and bulk purchases. The price difference reflects the distinct use cases, with SMA connectors favored in high-frequency, high-performance environments, while BNC connectors remain popular for general-purpose RF connections with tighter budget constraints.

Compatibility and Interchangeability

SMA connectors feature a threaded interface ensuring secure connections, commonly used in RF applications up to 18 GHz, while BNC connectors utilize a bayonet locking mechanism suitable for frequencies up to 4 GHz. These connectors are not directly interchangeable due to differing coupling methods and impedance specifications, with SMA typically at 50 ohms and BNC available in 50 or 75 ohms variants. Adapters can bridge compatibility gaps, but inherent mechanical and electrical differences limit seamless substitution in high-frequency systems.

Choosing the Right Connector: SMA or BNC

Choosing between SMA and BNC connectors depends on frequency range and application requirements; SMA connectors support higher frequencies up to 18 GHz with superior performance in RF and microwave systems, while BNC connectors are typically limited to 4 GHz and suit lower-frequency applications. SMA connectors offer threaded coupling for secure, vibration-resistant connections, making them ideal for precision test equipment and wireless communication devices, whereas BNC's bayonet coupling enables quick connect/disconnect in broadcast and video signal environments. Consider factors such as impedance stability (SMA at 50 ohms versus BNC available in 50 or 75 ohms), durability, and ease of use to select the connector best aligned with your system's technical and environmental needs.

SMA Infographic

libterm.com

libterm.com