Stepper motors provide precise control over position and speed, making them ideal for applications requiring accurate movement, such as 3D printers, CNC machines, and robotics. Their ability to move in discrete steps ensures repeatability and reliability in automation processes. Explore the rest of the article to understand how a stepper motor can enhance your project's performance.

Table of Comparison

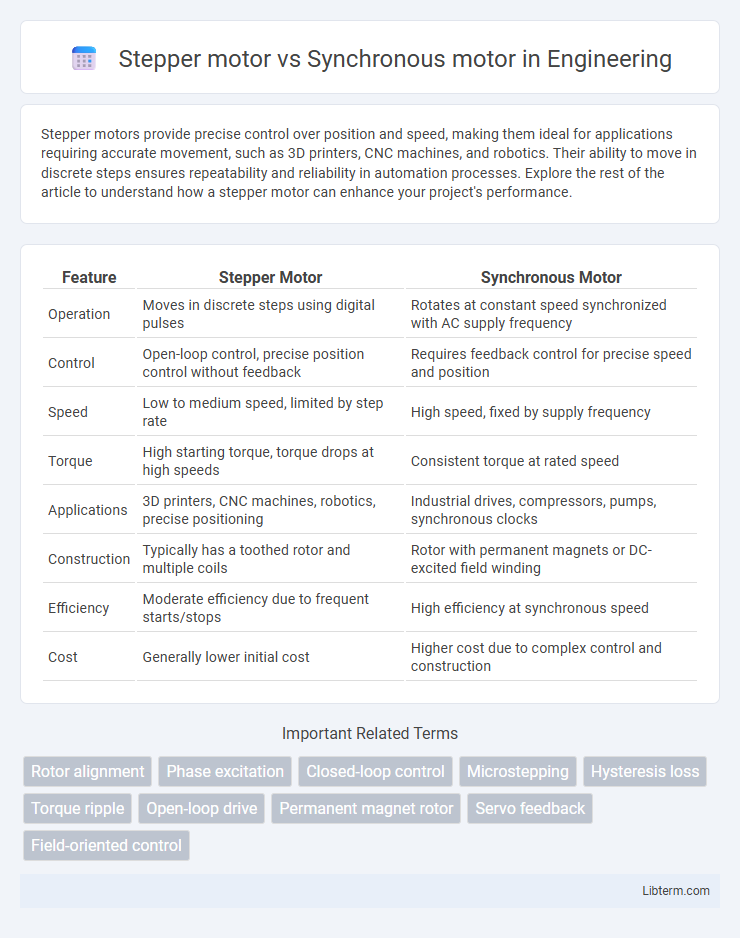

| Feature | Stepper Motor | Synchronous Motor |

|---|---|---|

| Operation | Moves in discrete steps using digital pulses | Rotates at constant speed synchronized with AC supply frequency |

| Control | Open-loop control, precise position control without feedback | Requires feedback control for precise speed and position |

| Speed | Low to medium speed, limited by step rate | High speed, fixed by supply frequency |

| Torque | High starting torque, torque drops at high speeds | Consistent torque at rated speed |

| Applications | 3D printers, CNC machines, robotics, precise positioning | Industrial drives, compressors, pumps, synchronous clocks |

| Construction | Typically has a toothed rotor and multiple coils | Rotor with permanent magnets or DC-excited field winding |

| Efficiency | Moderate efficiency due to frequent starts/stops | High efficiency at synchronous speed |

| Cost | Generally lower initial cost | Higher cost due to complex control and construction |

Introduction to Stepper and Synchronous Motors

Stepper motors convert electrical pulses into precise mechanical movements through discrete steps, providing accurate position control ideal for CNC machines and 3D printers. Synchronous motors operate by rotating at a speed directly proportional to the frequency of the supply current, ensuring constant speed for industrial applications like power generation and conveyor systems. Both motor types rely on magnetic fields, but stepper motors emphasize incremental positioning, while synchronous motors focus on maintaining synchronous speed under load.

Fundamental Working Principles

Stepper motors operate by dividing a full rotation into equal steps, using electromagnetic coils to sequentially energize and create precise angular movements controlled by digital pulses. Synchronous motors maintain constant speed by synchronizing the rotor's magnetic field with the rotating magnetic field of the stator, ensuring the rotor spins at the same frequency as the supply current. The fundamental difference lies in stepper motors using discrete steps for position control, while synchronous motors provide continuous rotation at a fixed speed.

Construction and Design Differences

Stepper motors feature multiple coils organized in phases around a rotor with permanent magnets or variable reluctance teeth, enabling precise control of angular position through sequential energizing of coils. Synchronous motors consist of a rotor with either permanent magnets or salient poles and a stator with sinusoidally distributed windings, designed to operate at synchronous speed with the rotating magnetic field of the stator. The stepper motor's construction facilitates incremental movement in discrete steps, while the synchronous motor's design supports continuous rotation synchronized with the stator's magnetic field frequency.

Motion Control and Precision

Stepper motors excel in motion control and precision by providing discrete, repeatable steps that enable accurate positioning without feedback systems, ideal for applications requiring exact angular displacement. Synchronous motors deliver smooth, continuous rotation synchronized with the power supply frequency, offering high efficiency and torque but typically require feedback mechanisms for precise position control. The choice between stepper and synchronous motors hinges on the required positional accuracy and the complexity of the control system.

Speed and Torque Characteristics

Stepper motors provide precise control over speed and position through discrete step increments, offering high torque at low speeds but experiencing torque reduction as speed increases. Synchronous motors maintain constant speed synchronized with the power supply frequency, delivering consistent torque across a wide speed range but typically requiring complex control for low-speed torque optimization. The choice between stepper and synchronous motors depends on the application's need for precise positioning versus consistent speed and torque performance.

Applications and Use Cases

Stepper motors excel in precise position control applications such as 3D printers, CNC machines, and robotics due to their ability to move in discrete steps without feedback systems. Synchronous motors are preferred in industrial settings requiring constant speed under varying loads, such as conveyor belts, large pumps, and compressors, because of their efficiency and stable operation. The choice between these motors depends on the need for accuracy and speed regulation versus power and efficiency in continuous operation scenarios.

Advantages and Disadvantages

Stepper motors offer precise position control and are ideal for applications requiring accurate stepwise movement, but they typically consume more power and produce less torque at high speeds compared to synchronous motors. Synchronous motors provide high efficiency, smooth operation, and consistent speed under varying loads, but they require complex control systems and are less suitable for applications needing precise incremental positioning. Choosing between them depends on the specific requirements for precision, torque, speed, and control complexity in the intended application.

Power Supply and Drive Requirements

Stepper motors require precise pulse signals from a specialized driver to control position and speed, typically powered by DC voltage with current limiting to prevent overheating. Synchronous motors operate on AC power with a constant frequency supply, often driven by variable frequency drives (VFDs) for speed control. The power supply for synchronous motors must maintain a stable frequency and voltage to ensure synchronism, whereas stepper motors rely on digital pulses for accurate movement without the need for a feedback system.

Maintenance and Reliability

Stepper motors require regular inspection of the rotor and stator for wear due to their discrete step operation, while synchronous motors often demand routine checks on brushes and slip rings in brush-type variants. Reliability in stepper motors is influenced by precise control electronics and can suffer from missed steps under heavy loads, whereas synchronous motors maintain consistent speed and torque with fewer control complexities, leading to higher long-term durability in industrial applications. Maintenance costs tend to be lower for synchronous motors due to fewer moving parts and less frequent adjustments compared to stepper motors prone to mechanical wear from repetitive stepping.

Choosing the Right Motor for Your Application

Selecting between a stepper motor and a synchronous motor depends on your application's precision and control requirements. Stepper motors excel in applications needing precise positioning and open-loop control, such as 3D printers and CNC machines, due to their ability to move in discrete steps. Synchronous motors are preferred for continuous, high-efficiency operation in applications like industrial conveyors or pumps where constant speed and torque are essential.

Stepper motor Infographic

libterm.com

libterm.com