Corner joints are essential in woodworking and construction, providing strength and stability where two pieces meet at a right angle. Different techniques like miter, dovetail, or box joints offer varying levels of durability and aesthetic appeal depending on your project requirements. Explore the article to discover the best corner joint methods and tips for your next build.

Table of Comparison

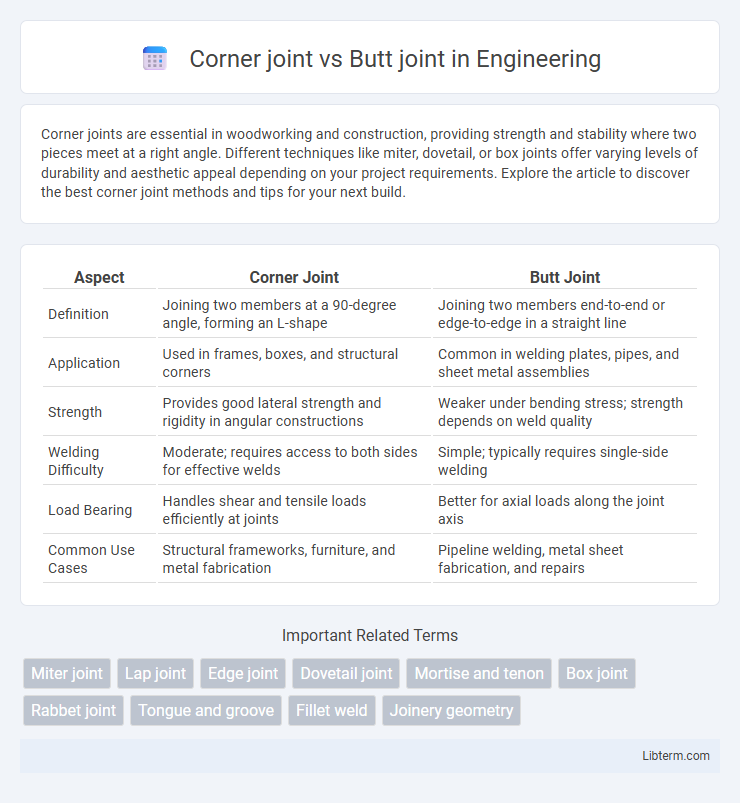

| Aspect | Corner Joint | Butt Joint |

|---|---|---|

| Definition | Joining two members at a 90-degree angle, forming an L-shape | Joining two members end-to-end or edge-to-edge in a straight line |

| Application | Used in frames, boxes, and structural corners | Common in welding plates, pipes, and sheet metal assemblies |

| Strength | Provides good lateral strength and rigidity in angular constructions | Weaker under bending stress; strength depends on weld quality |

| Welding Difficulty | Moderate; requires access to both sides for effective welds | Simple; typically requires single-side welding |

| Load Bearing | Handles shear and tensile loads efficiently at joints | Better for axial loads along the joint axis |

| Common Use Cases | Structural frameworks, furniture, and metal fabrication | Pipeline welding, metal sheet fabrication, and repairs |

Introduction to Corner Joint and Butt Joint

Corner joints connect two pieces of material at a right angle, commonly used in frame construction and box making for enhanced structural integrity. Butt joints join two pieces end-to-end or edge-to-edge without overlapping, offering simplicity but less strength compared to corner joints. Understanding the differences helps in selecting the appropriate joint type for woodworking or metalworking projects based on strength and application requirements.

Definition of Corner Joint

A corner joint is a woodworking or metalworking technique where two pieces meet at a right angle, forming an "L" shape ideal for constructing frames or boxes. This joint offers structural stability by aligning the ends and edges of materials, often reinforced with adhesives, nails, or welding. In contrast, a butt joint simply joins two pieces end-to-end or edge-to-edge without overlapping, making it less strong without additional reinforcement.

Definition of Butt Joint

A butt joint is a simple woodworking or metalworking joint where two pieces are joined end to end without overlapping or interlocking, typically meeting at a right angle. Commonly used in frame construction and simple box designs, butt joints rely heavily on adhesives, fasteners, or welding for strength due to their limited mechanical interlock. Unlike corner joints, which may involve more complex joining techniques for increased stability, butt joints prioritize ease of assembly and minimal material preparation.

Key Differences Between Corner and Butt Joints

Corner joints connect two pieces of material at a 90-degree angle forming an L-shape, offering structural strength ideal for frames and boxes, whereas butt joints join the ends of two pieces in a straight line, often requiring reinforcement due to weaker load-bearing capacity. Corner joints typically involve more complex techniques such as mitering or adding gussets, while butt joints are simpler but less durable without nails, screws, or adhesives. Understanding these differences is crucial for selecting the appropriate joint type based on the mechanical stress and aesthetic requirements of woodworking or metalworking projects.

Strength Comparison: Corner Joint vs Butt Joint

Corner joints generally provide greater strength compared to butt joints due to increased surface area for adhesive or fastener application and improved load distribution. Butt joints, while simpler and faster to assemble, tend to be weaker under stress as they rely mainly on end grain adhesion, which reduces overall joint durability. Woodworkers often reinforce butt joints with dowels, biscuits, or screws to enhance strength, whereas corner joints naturally offer more robust mechanical interlocking.

Common Applications of Corner Joints

Corner joints are widely used in woodworking and metalworking for constructing frames, boxes, and furniture, providing strong right-angle connections. These joints are commonly found in cabinet making, door frames, and picture frames due to their ability to create stable and durable corners. Their versatility and ease of reinforcement with fasteners or adhesives make corner joints ideal for load-bearing and decorative applications.

Common Applications of Butt Joints

Butt joints are widely used in woodworking, metalworking, and construction due to their simplicity and ease of assembly, often found in frame making, cabinetry, and basic furniture design. They provide sufficient strength for non-load-bearing structures and are frequently employed in joining panels, boards, and pipes where quick and straightforward connections are required. Despite their lower strength compared to other joints, butt joints are ideal in applications where reinforcement with nails, screws, or adhesives is feasible.

Advantages and Disadvantages

Corner joints offer superior strength and aesthetic appeal in woodworking and metal fabrication, making them ideal for frames and boxes. They provide greater resistance to shear and tension forces compared to butt joints, which are simpler and quicker to create but lack structural integrity and are prone to weaker bonding. Butt joints are advantageous for rapid assembly and cost-effectiveness but often require reinforcement with screws, dowels, or adhesives to improve durability.

Material and Tool Considerations

Corner joints require precise cutting tools like miter saws or routers to create angled edges, often demanding higher-quality materials such as hardwoods or plywood for structural stability and aesthetic appeal. Butt joints use simpler tools like saws and clamps, making them suitable for softer woods or composite materials, but they often require reinforcement like screws, nails, or adhesives to enhance strength. Material density and grain orientation significantly affect joint durability, influencing tool choice and finishing techniques for both corner and butt joints.

Choosing the Right Joint for Your Project

Selecting the right joint depends on project requirements such as strength, aesthetics, and material type. Corner joints provide strong, clean edges ideal for frames and boxes, while butt joints are simpler and quicker, suitable for basic assemblies with moderate load. Evaluate factors like load direction, visibility, and woodworking skill to ensure optimal joint selection.

Corner joint Infographic

libterm.com

libterm.com