Frictional resistance is the force that opposes the motion of objects sliding against each other, arising from surface roughness and material properties. It plays a critical role in engineering applications, vehicle dynamics, and everyday activities by affecting energy efficiency and wear. Discover how understanding frictional resistance can optimize Your designs and enhance performance in the complete article.

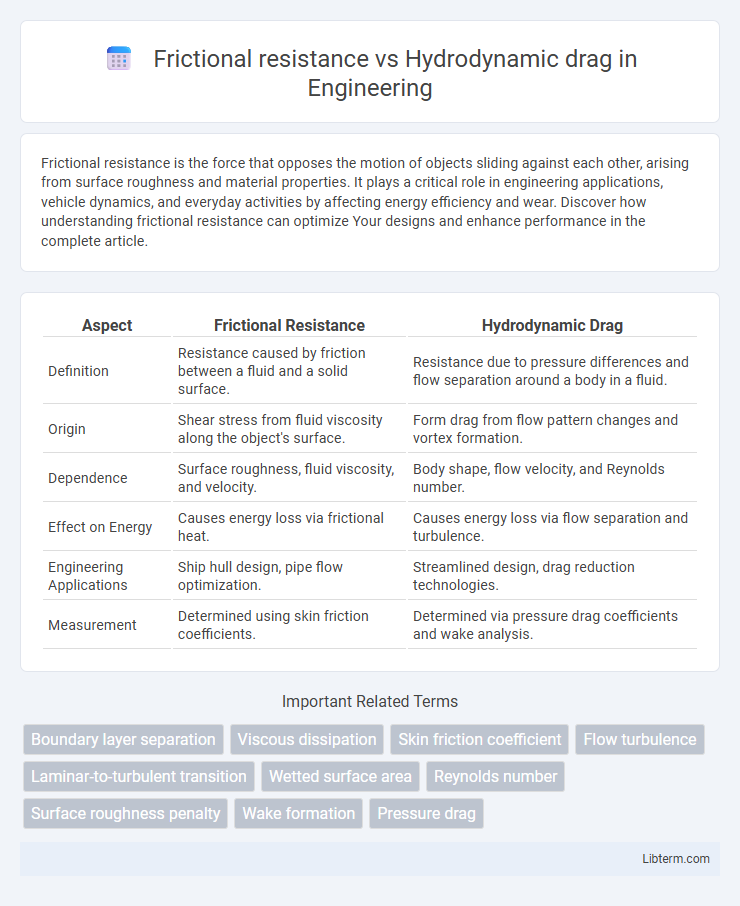

Table of Comparison

| Aspect | Frictional Resistance | Hydrodynamic Drag |

|---|---|---|

| Definition | Resistance caused by friction between a fluid and a solid surface. | Resistance due to pressure differences and flow separation around a body in a fluid. |

| Origin | Shear stress from fluid viscosity along the object's surface. | Form drag from flow pattern changes and vortex formation. |

| Dependence | Surface roughness, fluid viscosity, and velocity. | Body shape, flow velocity, and Reynolds number. |

| Effect on Energy | Causes energy loss via frictional heat. | Causes energy loss via flow separation and turbulence. |

| Engineering Applications | Ship hull design, pipe flow optimization. | Streamlined design, drag reduction technologies. |

| Measurement | Determined using skin friction coefficients. | Determined via pressure drag coefficients and wake analysis. |

Introduction to Frictional Resistance and Hydrodynamic Drag

Frictional resistance arises from the direct contact between fluid molecules and a solid surface, causing energy loss as fluid layers slide over each other. Hydrodynamic drag encompasses the total resistive forces acting on a body moving through a fluid, including both frictional resistance and pressure drag caused by flow separation. Understanding the balance between frictional resistance and hydrodynamic drag is essential for optimizing vessel hull design and reducing energy consumption in marine engineering.

Fundamental Definitions: Frictional vs Hydrodynamic Forces

Frictional resistance refers to the force generated by the interaction between a solid surface and a fluid, primarily caused by the viscosity of the fluid and the roughness of the surface. Hydrodynamic drag encompasses the total resistance a body experiences moving through a fluid, including both frictional resistance and pressure drag resulting from flow separation and wake formation. Understanding the distinction between frictional forces, dependent on the boundary layer characteristics, and hydrodynamic forces, influenced by overall fluid flow patterns, is essential in fluid mechanics and naval architecture.

Physical Principles Behind Frictional Resistance

Frictional resistance arises from the molecular interaction between a fluid and a solid surface, governed by the no-slip condition where fluid velocity matches the surface velocity, creating viscous shear forces. This resistance depends on fluid viscosity, surface roughness, and flow velocity, impacting boundary layer development and energy loss in fluid flow systems. Hydrodynamic drag encompasses frictional resistance and pressure drag, with frictional resistance specifically related to viscous forces resisting motion at the interface of fluid and solid surfaces.

Understanding Hydrodynamic Drag Mechanisms

Hydrodynamic drag arises from the interaction between an object's surface and fluid flow, primarily caused by viscous shear forces and pressure differences. Unlike frictional resistance, which is dominated by surface roughness and molecular contact, hydrodynamic drag includes both skin friction drag and form drag resulting from flow separation and wake formation. Understanding the boundary layer behavior and turbulence intensity is crucial for optimizing shapes to minimize drag in marine vessels and underwater vehicles.

Key Factors Influencing Frictional Resistance

Frictional resistance is primarily influenced by surface roughness and fluid viscosity, which create shear stress along the fluid-solid interface in naval and aeronautical engineering contexts. The Reynolds number and flow velocity also play critical roles, affecting the boundary layer characteristics that determine frictional drag magnitudes. Understanding these key factors enables optimized hull and airfoil designs to minimize energy losses due to frictional resistance, contrasting with hydrodynamic drag that includes pressure drag components.

Variables Affecting Hydrodynamic Drag

Hydrodynamic drag is influenced primarily by variables such as fluid velocity, fluid density, surface roughness, and the shape and size of the object moving through the fluid. Higher fluid velocity and increased surface roughness typically result in greater drag forces due to increased turbulence and frictional effects at the fluid-object interface. Fluid viscosity and the Reynolds number also play crucial roles in determining the flow regime and, consequently, the magnitude of hydrodynamic drag.

Comparative Analysis: Frictional Resistance vs Hydrodynamic Drag

Frictional resistance primarily arises from the interaction between a fluid and the surface of a moving object, significantly influenced by surface roughness and fluid viscosity, whereas hydrodynamic drag encompasses both frictional resistance and pressure drag caused by flow separation and wake formation. Frictional resistance tends to dominate at low speeds and streamlined shapes, while hydrodynamic drag becomes more prominent at higher velocities and bluff body configurations. Understanding the balance of these forces is crucial for optimizing vessel hull designs to minimize total drag and improve fuel efficiency.

Methods to Measure and Calculate Each Force

Frictional resistance is typically measured using direct force sensors or through experimental setups like towing tanks, where surface roughness and wetted surface area data enable calculation based on the ITTC 1957 friction line formula. Hydrodynamic drag combines frictional resistance and pressure drag and is often quantified using computational fluid dynamics (CFD) simulations alongside drag balance experiments that analyze flow patterns and pressure distribution around the body. Advanced methods involve laser Doppler velocimetry (LDV) for velocity field measurements and empirical correlations derived from Reynolds number to accurately separate and calculate each force component.

Reduction Strategies for Both Frictional and Hydrodynamic Losses

Reducing frictional resistance involves using advanced lubricants and smooth surface coatings to minimize contact friction between moving parts, while hydrodynamic drag reduction focuses on streamlining shapes and applying low-drag hull designs or surfaces with riblets to manage fluid flow. Technologies such as boundary layer control, air lubrication systems, and compliant surface materials optimize performance by decreasing viscous forces and turbulence-induced drag. Integrating computational fluid dynamics (CFD) simulations aids in refining these strategies, leading to enhanced energy efficiency in marine vessels and aerodynamic vehicles.

Real-world Applications and Implications in Marine Engineering

Frictional resistance, caused by the viscosity of water acting on the ship's hull surface, is a critical factor in marine engineering, directly affecting fuel efficiency and vessel speed. Hydrodynamic drag encompasses both frictional resistance and wave-making resistance, influencing hull design, propulsion systems, and operational costs in commercial shipping and naval architecture. Optimizing hull coatings and streamlined shapes minimizes frictional resistance, while advanced computational fluid dynamics models predict hydrodynamic drag to enhance performance and reduce environmental impact in real-world applications.

Frictional resistance Infographic

libterm.com

libterm.com