A soldered joint creates a reliable electrical connection by melting a filler metal to bond two components without melting the base materials. This process ensures strong mechanical strength and excellent conductivity, essential for electronics and plumbing applications. Explore the rest of the article to learn how to achieve perfect soldered joints for your projects.

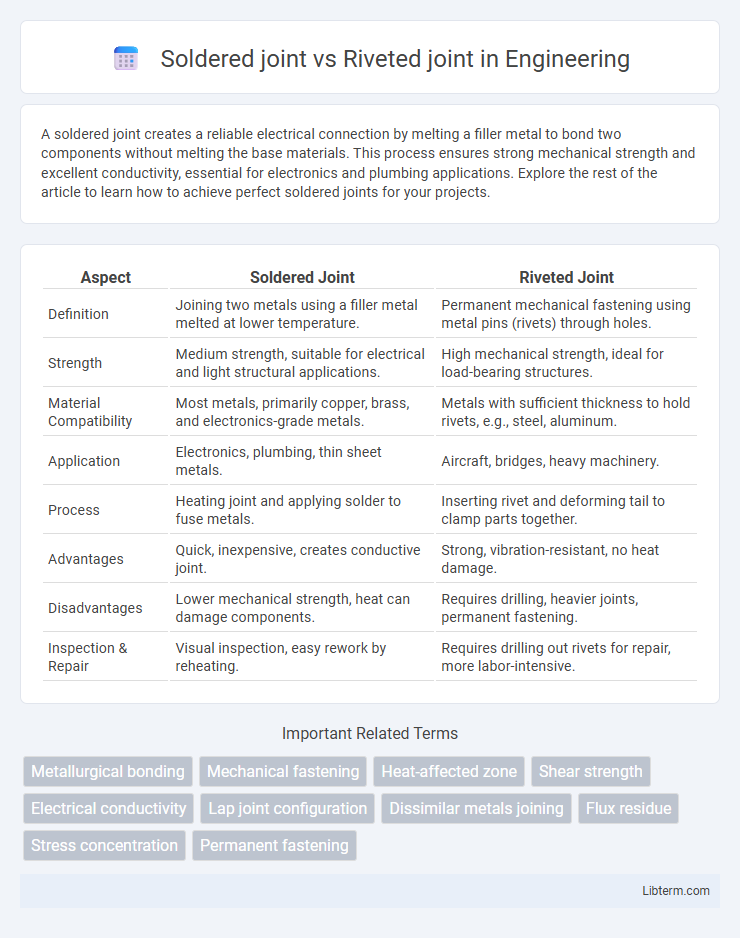

Table of Comparison

| Aspect | Soldered Joint | Riveted Joint |

|---|---|---|

| Definition | Joining two metals using a filler metal melted at lower temperature. | Permanent mechanical fastening using metal pins (rivets) through holes. |

| Strength | Medium strength, suitable for electrical and light structural applications. | High mechanical strength, ideal for load-bearing structures. |

| Material Compatibility | Most metals, primarily copper, brass, and electronics-grade metals. | Metals with sufficient thickness to hold rivets, e.g., steel, aluminum. |

| Application | Electronics, plumbing, thin sheet metals. | Aircraft, bridges, heavy machinery. |

| Process | Heating joint and applying solder to fuse metals. | Inserting rivet and deforming tail to clamp parts together. |

| Advantages | Quick, inexpensive, creates conductive joint. | Strong, vibration-resistant, no heat damage. |

| Disadvantages | Lower mechanical strength, heat can damage components. | Requires drilling, heavier joints, permanent fastening. |

| Inspection & Repair | Visual inspection, easy rework by reheating. | Requires drilling out rivets for repair, more labor-intensive. |

Introduction to Soldered and Riveted Joints

Soldered joints are created by melting a filler metal with a low melting point to join two metal surfaces without melting the base materials, commonly used in electronics and plumbing for creating strong, conductive connections. Riveted joints involve fastening two or more metal components using a metal pin or rivet that is deformed to hold the parts together, typically employed in structural applications like bridges, aircraft, and shipbuilding for durable mechanical bonds. Both methods provide reliable metal joining solutions but differ significantly in application, strength, and material compatibility.

Definition and Basic Concepts

A soldered joint is a permanent connection formed by melting a filler metal with a low melting point to join two metal surfaces without melting the base materials. A riveted joint involves mechanically fastening two or more metal pieces using metal pins or rivets, which are deformed to hold the parts together. Both methods ensure structural integrity but differ in thermal application, with soldered joints relying on metallurgical bonding and riveted joints depending on mechanical fastening.

Types of Soldered Joints

Types of soldered joints include lap joints, butt joints, and T-joints, each offering different mechanical strengths and electrical conductivity suited for electronics and metalwork. Lap joints involve overlapping two metal pieces, creating a strong bond ideal for sheet metals, while butt joints join two pieces end-to-end for a streamlined finish. T-joints, formed by attaching one piece perpendicular to another, provide structural support in frames and piping systems, emphasizing versatility in soldering applications.

Types of Riveted Joints

Types of riveted joints include lap joints, butt joints with single cover plates, and butt joints with double cover plates, each designed to distribute stress efficiently in mechanical structures. Lap joints overlap two plates and are commonly used for connecting sheets, while butt joints align plates end-to-end with cover plates providing additional strength. Understanding these types is crucial for selecting the appropriate joint based on load, material thickness, and application requirements.

Material Compatibility and Selection

Soldered joints excel in joining dissimilar metals such as copper, silver, and gold due to their low-temperature bonding process, preserving material integrity without causing thermal distortion. Riveted joints require careful selection of compatible metals to prevent galvanic corrosion, with aluminum and steel often paired using protective coatings or insulating materials. Material compatibility in soldered joints prioritizes thermal expansion coefficients, while in riveted joints, mechanical strength and corrosion resistance dominate selection criteria.

Strength and Durability Comparison

Soldered joints provide uniform conductivity and moderate mechanical strength, making them suitable for electrical connections requiring corrosion resistance but limited load-bearing capacity. Riveted joints offer superior shear strength and durability under dynamic stresses, making them ideal for structural applications with heavy mechanical loads. The choice between soldered and riveted joints hinges on the balance between electrical performance and mechanical robustness in the intended use case.

Applications in Industry

Soldered joints are extensively used in the electronics industry for connecting delicate components on printed circuit boards, offering precise electrical conductivity and mechanical stability. Riveted joints find widespread application in aerospace and automotive industries where high-strength, fatigue-resistant connections are required for structural assemblies. The choice between soldered and riveted joints depends on factors such as load-bearing capacity, environmental exposure, and ease of repair in industrial applications.

Advantages of Soldered Joints

Soldered joints provide superior electrical conductivity and excellent thermal resistance, making them ideal for electronic and electrical applications. The process creates a seamless, corrosion-resistant bond that enhances mechanical strength and ensures long-term reliability. Soldering also allows for precise, clean connections that support miniaturization in complex circuit assemblies.

Advantages of Riveted Joints

Riveted joints provide superior mechanical strength and vibration resistance, making them ideal for heavy-duty structural applications such as bridges and aircraft. They allow for easy inspection and maintenance since rivets can be visually examined for integrity, unlike soldered joints which may conceal defects. Riveting also supports joining dissimilar materials without compromising joint quality, ensuring durability in varying environmental conditions.

Choosing the Right Joint for Your Project

Selecting the right joint depends on the project's mechanical strength requirements and material compatibility; soldered joints offer excellent electrical conductivity and are ideal for delicate electronics, while riveted joints provide superior mechanical strength for structural applications. Soldered joints require clean, heat-tolerant materials and precise temperature control, whereas riveted joints suit thicker, tougher materials needing high shear strength. Consider factors such as load type, environmental exposure, and assembly speed to determine whether a soldered or riveted joint optimizes durability and functionality.

Soldered joint Infographic

libterm.com

libterm.com