Mechanical systems are integral to numerous industries, enabling the efficient transfer of energy and motion through components such as gears, levers, and engines. Understanding their design and function can greatly enhance the reliability and performance of machinery in applications ranging from automotive to manufacturing. Explore the rest of the article to discover how your knowledge of mechanical systems can improve practical solutions and innovations.

Table of Comparison

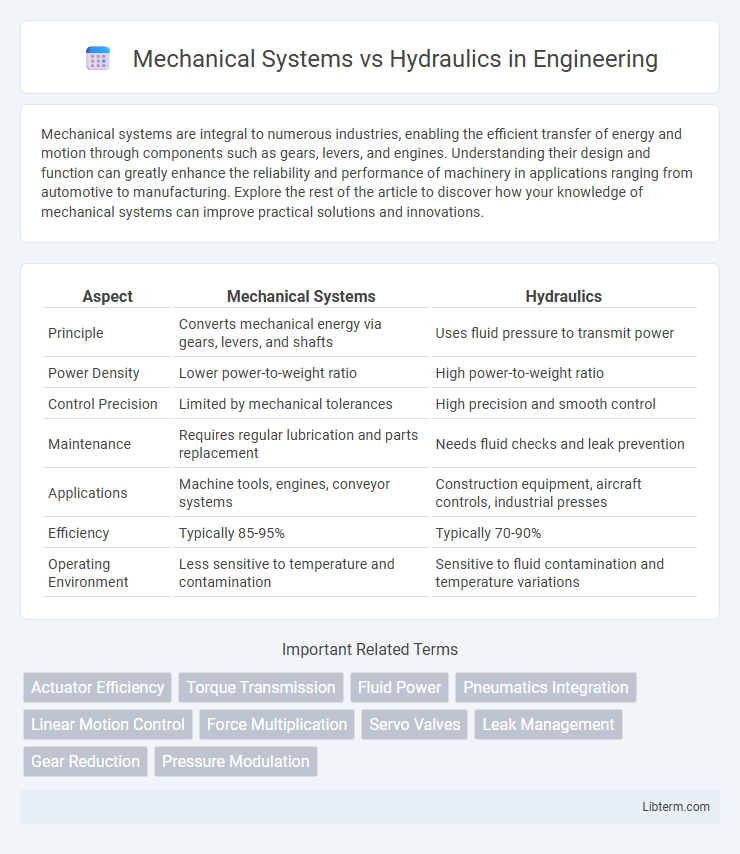

| Aspect | Mechanical Systems | Hydraulics |

|---|---|---|

| Principle | Converts mechanical energy via gears, levers, and shafts | Uses fluid pressure to transmit power |

| Power Density | Lower power-to-weight ratio | High power-to-weight ratio |

| Control Precision | Limited by mechanical tolerances | High precision and smooth control |

| Maintenance | Requires regular lubrication and parts replacement | Needs fluid checks and leak prevention |

| Applications | Machine tools, engines, conveyor systems | Construction equipment, aircraft controls, industrial presses |

| Efficiency | Typically 85-95% | Typically 70-90% |

| Operating Environment | Less sensitive to temperature and contamination | Sensitive to fluid contamination and temperature variations |

Introduction to Mechanical and Hydraulic Systems

Mechanical systems utilize gears, levers, and shafts to transmit and control power through direct physical motion, offering precise mechanical advantage in various applications. Hydraulic systems rely on pressurized fluid within cylinders and valves to generate force and movement, enabling smooth and powerful operation in heavy machinery. Understanding the principles of force transmission, energy conversion, and control mechanisms is essential for optimizing performance and efficiency in both mechanical and hydraulic systems.

Core Principles of Mechanical Systems

Mechanical systems operate on the fundamental principles of force, motion, and energy transfer through rigid components such as gears, levers, and pulleys. These systems convert input energy into mechanical work by utilizing Newton's laws of motion, emphasizing torque, friction, and mechanical advantage. Unlike hydraulics, mechanical systems rely on solid parts to transmit power without fluid mediums, ensuring precise control and direct force application.

Fundamentals of Hydraulic Systems

Hydraulic systems utilize incompressible fluids to transmit power through pressurized liquid, enabling precise control and high force output in mechanical operations. Core components include pumps, valves, actuators, and fluid reservoirs, working together to convert mechanical energy into hydraulic energy and back. Understanding fluid dynamics, pressure regulation, and flow control is essential for optimizing efficiency and performance in hydraulic machinery compared to purely mechanical systems.

Key Components: Mechanical vs Hydraulic

Mechanical systems primarily utilize gears, levers, pulleys, and shafts to transmit and control motion, relying on solid components to provide force and movement. Hydraulic systems depend on pumps, valves, cylinders, and fluid reservoirs to transfer energy through pressurized liquids, enabling smooth and powerful motion control. The key difference lies in mechanical components delivering direct physical interaction, whereas hydraulic components use fluid dynamics to achieve force amplification and precise control.

Power Transmission Efficiency Compared

Mechanical systems typically offer power transmission efficiencies ranging from 85% to 95%, depending on the design and type of components used, such as gears, belts, and shafts. Hydraulic systems, while providing high force output and flexibility, often exhibit lower efficiencies between 70% and 85% due to fluid friction, leakage, and pump losses. Efficiency in mechanical power transmission remains higher because it involves direct contact and less energy loss compared to the fluid dynamics and pressure drops inherent in hydraulic systems.

Maintenance and Reliability Insights

Mechanical systems rely on physical components such as gears, bearings, and shafts that require routine lubrication and inspection to prevent wear and tear, ensuring consistent performance and reducing downtime. In contrast, hydraulic systems depend on fluid power, which necessitates regular fluid checks, filter replacements, and leak inspections to maintain system pressure and avoid contamination-related failures. Reliability in mechanical systems is often increased through robust design and preventive maintenance, while hydraulic systems demand vigilance in fluid quality and seal integrity to prevent costly breakdowns.

Cost Considerations and Lifespan

Mechanical systems typically have lower upfront costs compared to hydraulic systems due to simpler components and fewer specialized parts. Hydraulic systems often incur higher maintenance expenses over time because of fluid leaks and seal replacements but offer longer lifespan under heavy load conditions. Evaluating total cost of ownership requires balancing initial investment, maintenance frequency, and the durability demands of the specific application.

Common Applications and Industries

Mechanical systems dominate in automotive manufacturing and heavy machinery due to their robustness and easy maintenance, while hydraulics excel in construction, aerospace, and agricultural industries for tasks requiring precise control and high force density. Hydraulic systems are preferred in excavators, aircraft control surfaces, and industrial presses because they provide smooth, powerful motion in compact spaces. Mechanical systems are commonly found in conveyor belts, gear drives, and engine components, benefiting industries focused on reliability and cost-efficiency.

Performance Factors: Speed, Force, Precision

Mechanical systems typically offer high speed but are limited in force output and precision due to friction and wear. Hydraulic systems deliver greater force and smooth, precise control at variable speeds, benefiting heavy-load applications and fine adjustments. The choice depends on balancing speed requirements with force capacity and the desired level of operational precision.

Choosing the Right System for Your Needs

Mechanical systems offer precise control and durability ideal for applications requiring consistent, repetitive motion with minimal maintenance. Hydraulics provide exceptional power density and smooth force control, making them suitable for heavy lifting and variable load conditions. Evaluating factors such as load capacity, environmental conditions, maintenance frequency, and cost efficiency ensures selecting the optimal system tailored to specific operational requirements.

Mechanical Systems Infographic

libterm.com

libterm.com