Concrete is a durable and versatile construction material composed of cement, water, and aggregates like sand and gravel, forming a strong foundation for buildings, roads, and infrastructure. Proper mixing and curing of concrete ensure its longevity and resistance to weathering, making it essential for various construction projects. Discover how to optimize concrete use and maintenance to enhance the strength and lifespan of your structures by reading the full article.

Table of Comparison

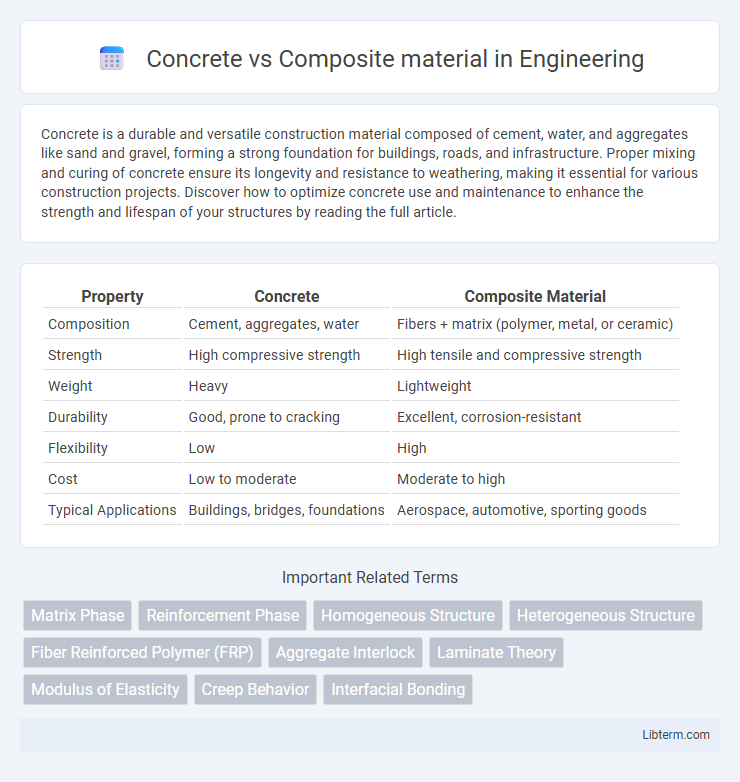

| Property | Concrete | Composite Material |

|---|---|---|

| Composition | Cement, aggregates, water | Fibers + matrix (polymer, metal, or ceramic) |

| Strength | High compressive strength | High tensile and compressive strength |

| Weight | Heavy | Lightweight |

| Durability | Good, prone to cracking | Excellent, corrosion-resistant |

| Flexibility | Low | High |

| Cost | Low to moderate | Moderate to high |

| Typical Applications | Buildings, bridges, foundations | Aerospace, automotive, sporting goods |

Introduction to Concrete and Composite Materials

Concrete is a widely used construction material known for its high compressive strength, durability, and versatility in forming structural elements. Composite materials combine two or more distinct constituents, such as fibers and matrices, to achieve enhanced mechanical properties like increased strength, stiffness, and toughness compared to traditional materials. The introduction of composite materials in construction offers improved performance characteristics and weight reduction, providing alternatives to conventional concrete in various engineering applications.

Composition and Structure Differences

Concrete consists primarily of cement, water, and aggregates such as sand and gravel, forming a rigid, homogeneous structure through hydration and curing. Composite materials combine two or more distinct constituents, typically a matrix and reinforcement (e.g., fibers or particles), resulting in a heterogeneous structure designed for enhanced mechanical properties. The fundamental difference lies in concrete's uniform matrix versus composites' engineered phase distributions tailored to optimize strength, durability, and weight.

Mechanical Properties Comparison

Concrete exhibits high compressive strength but relatively low tensile strength and brittleness, limiting its ability to withstand dynamic loads and impact. Composite materials, such as fiber-reinforced polymers, combine materials with different mechanical properties to achieve superior tensile strength, toughness, and fatigue resistance compared to concrete. The tailored anisotropy and improved strain capacity of composites enable enhanced performance in structural applications requiring both strength and flexibility.

Durability and Longevity

Concrete offers high durability due to its resistance to weathering, corrosion, and fire, making it ideal for long-lasting infrastructure. Composite materials combine various substances like fibers and resins, resulting in enhanced strength-to-weight ratios and superior resistance to fatigue and environmental degradation. While concrete endures harsh conditions over decades, composites provide extended longevity in applications requiring flexibility and reduced maintenance.

Weight and Density Considerations

Concrete typically has a density ranging from 2,200 to 2,400 kg/m3, making it significantly heavier than most composite materials, which often range between 1,200 and 1,800 kg/m3 depending on the fiber and matrix used. The lower density of composite materials translates to reduced structural weight, improving fuel efficiency and load capacity in applications such as aerospace and automotive engineering. Weight savings achieved through composites enhance performance and reduce transportation costs, making density a critical factor in material selection.

Cost and Economic Factors

Concrete offers lower initial material and labor costs compared to composite materials, making it a cost-effective choice for large-scale construction projects. Composite materials, while having higher upfront expenses, provide superior durability and reduced maintenance costs over time, leading to better long-term economic value. Lifecycle cost analysis often favors composites in applications requiring high strength-to-weight ratios and resistance to environmental degradation.

Environmental Impact and Sustainability

Concrete production generates significant CO2 emissions due to cement manufacturing, contributing to environmental concerns such as global warming and resource depletion. Composite materials, often incorporating recycled fibers and resins, offer enhanced durability and lower carbon footprints, making them more sustainable alternatives in construction. The adoption of composites can reduce waste and improve energy efficiency throughout the lifecycle of infrastructure projects.

Common Applications in Construction

Concrete is widely used in foundations, bridges, highways, and high-rise buildings due to its strength, durability, and cost-effectiveness. Composite materials, combining fibers with a resin matrix, are favored for lightweight structural panels, roofing, facades, and reinforcing elements in modern construction, offering high strength-to-weight ratios and corrosion resistance. The choice between concrete and composite materials depends on specific project needs such as load-bearing capacity, environmental exposure, and design flexibility.

Maintenance and Lifecycle Performance

Concrete requires regular sealing and crack repair to prevent water infiltration and freeze-thaw damage, which can increase maintenance efforts over its lifespan. Composite materials exhibit superior durability with minimal maintenance since they resist corrosion, rot, and chemical exposure, extending their lifecycle performance. Lifecycle cost analysis often favors composites for long-term projects due to reduced repair frequency and enhanced structural longevity.

Choosing the Right Material: Key Factors to Consider

Choosing between concrete and composite materials depends on key factors such as strength-to-weight ratio, durability, and environmental conditions of the project. Concrete offers excellent compressive strength and fire resistance, making it ideal for heavy load-bearing structures, while composites provide superior tensile strength and corrosion resistance, suited for lightweight and flexible applications. Cost-effectiveness, maintenance requirements, and long-term performance under specific environmental stresses also play critical roles in material selection.

Concrete Infographic

libterm.com

libterm.com