The Stirling cycle refrigeration system operates on the Stirling thermodynamic cycle, using a regenerative process to transfer heat and achieve cooling efficiently. This system employs a closed-cycle mechanism with a working gas, typically helium or hydrogen, which undergoes cyclic compression and expansion, resulting in temperature differentials suitable for refrigeration. Explore the article to understand how your cooling needs can benefit from this innovative and energy-efficient technology.

Table of Comparison

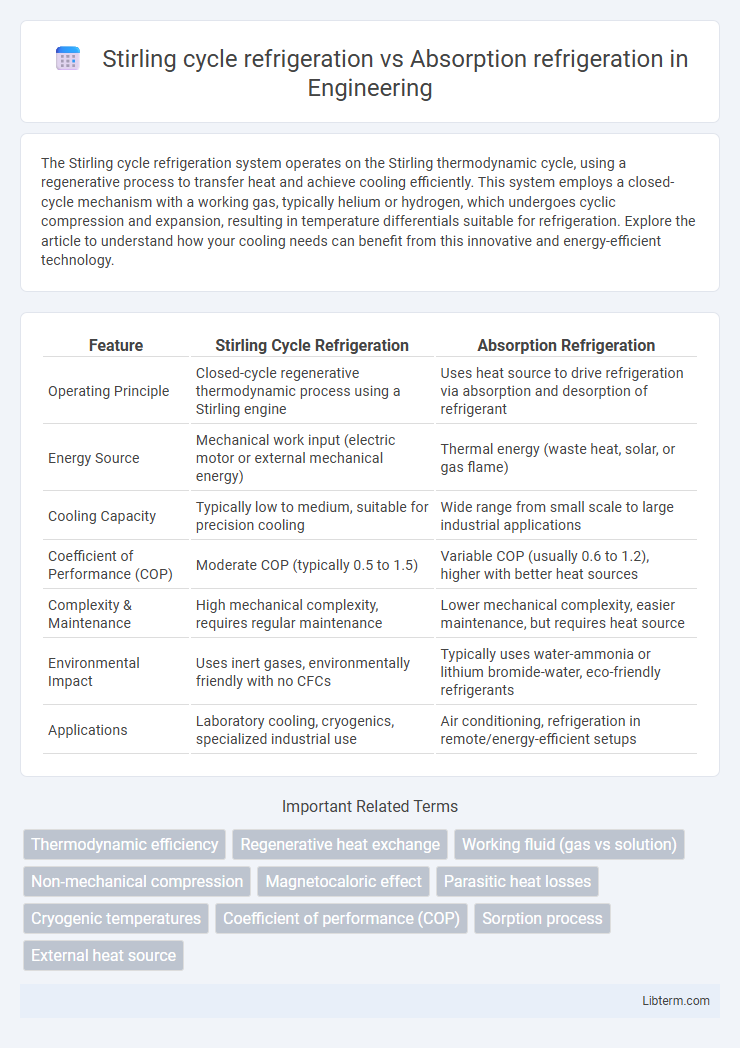

| Feature | Stirling Cycle Refrigeration | Absorption Refrigeration |

|---|---|---|

| Operating Principle | Closed-cycle regenerative thermodynamic process using a Stirling engine | Uses heat source to drive refrigeration via absorption and desorption of refrigerant |

| Energy Source | Mechanical work input (electric motor or external mechanical energy) | Thermal energy (waste heat, solar, or gas flame) |

| Cooling Capacity | Typically low to medium, suitable for precision cooling | Wide range from small scale to large industrial applications |

| Coefficient of Performance (COP) | Moderate COP (typically 0.5 to 1.5) | Variable COP (usually 0.6 to 1.2), higher with better heat sources |

| Complexity & Maintenance | High mechanical complexity, requires regular maintenance | Lower mechanical complexity, easier maintenance, but requires heat source |

| Environmental Impact | Uses inert gases, environmentally friendly with no CFCs | Typically uses water-ammonia or lithium bromide-water, eco-friendly refrigerants |

| Applications | Laboratory cooling, cryogenics, specialized industrial use | Air conditioning, refrigeration in remote/energy-efficient setups |

Introduction to Refrigeration Cycles

Refrigeration cycles are essential for transferring heat from a low-temperature region to a high-temperature region, with the Stirling cycle and absorption refrigeration representing two distinct methods. The Stirling cycle refrigeration utilizes a closed regenerative thermodynamic process involving compression and expansion of a working gas, offering high efficiency and environmental benefits. Absorption refrigeration relies on heat-driven absorption and desorption processes using a refrigerant-absorbent pair, enabling operation without mechanical compressors and often utilizing waste heat or solar energy.

Overview of Stirling Cycle Refrigeration

Stirling cycle refrigeration operates on the Stirling engine principle, utilizing cyclic compression and expansion of a working gas to transfer heat for cooling purposes. It achieves high efficiency through precise temperature control and reversible thermodynamic processes, making it suitable for applications requiring quiet and vibration-free operation. In contrast, absorption refrigeration relies on a heat source to drive a refrigerant-absorbent cycle, typically offering lower mechanical complexity but reduced efficiency compared to Stirling cycle systems.

Fundamentals of Absorption Refrigeration

Absorption refrigeration relies on a heat source to drive the refrigeration cycle, utilizing a refrigerant-absorbent pair such as water and lithium bromide, rather than mechanical compression found in Stirling cycle refrigeration. The process involves evaporation of the refrigerant at low pressure to absorb heat, followed by absorption into the absorbent and subsequent desorption using thermal energy, enabling continuous cooling without moving parts. This fundamental reliance on thermal energy makes absorption refrigeration suitable for waste heat recovery and solar-powered applications, contrasting with the mechanically driven Stirling cycle refrigeration system.

Working Principle: Stirling vs Absorption

The Stirling cycle refrigeration operates based on cyclic compression and expansion of a working gas, typically helium or hydrogen, to transfer heat by exploiting temperature differences generated through a regenerator. Absorption refrigeration utilizes a heat-driven process where a refrigerant is absorbed by a liquid absorbent, separated by heat input in a generator, then condensed and evaporated to produce cooling. Stirling systems rely on mechanical pistons and regenerator efficiency, while absorption systems depend on thermochemical properties and heat for operation.

Energy Efficiency Comparison

Stirling cycle refrigeration systems typically achieve higher energy efficiency with coefficients of performance (COP) ranging from 0.4 to 0.6, relying on external heat sources and regenerative heat exchange to minimize energy losses. Absorption refrigeration cycles generally have lower COP values, around 0.5 to 0.7, but can utilize waste heat or solar thermal energy, offering better overall system efficiency in specific applications despite higher thermal input requirements. The Stirling cycle excels in mechanical energy input efficiency, while absorption refrigeration benefits from flexible heat source utilization, impacting their comparative energy efficiency depending on operational context.

Environmental Impact Analysis

Stirling cycle refrigeration systems utilize non-toxic working fluids and operate on external combustion, resulting in lower greenhouse gas emissions compared to traditional vapor compression systems. Absorption refrigeration employs refrigerants like ammonia or water-lithium bromide solutions, offering reduced environmental harm due to non-CFC/HCFC refrigerants but can emit ammonia, posing toxicity concerns. Life cycle assessments reveal Stirling cycle units have higher energy efficiency, minimizing fossil fuel consumption and carbon footprint, while absorption systems benefit from waste heat utilization, enhancing sustainability in specific industrial applications.

Applications and Industry Usage

Stirling cycle refrigeration is commonly used in cryogenics, aerospace, and specialized cooling systems due to its high efficiency and capability for precise temperature control. Absorption refrigeration finds widespread application in industrial settings such as chemical processing, gas liquefaction, and HVAC systems, especially where waste heat or solar energy can be utilized. Both systems serve niche markets, with Stirling units favored for low-temperature requirements and absorption units preferred for large-scale, low-maintenance cooling solutions.

Maintenance and Operational Considerations

Stirling cycle refrigeration systems require precise mechanical maintenance due to moving parts like pistons and seals, necessitating regular inspections to prevent wear and maintain efficiency. Absorption refrigeration systems have fewer moving components, resulting in lower mechanical maintenance but demand careful monitoring of the solution concentration and heat source stability to ensure optimal operation. Operational costs favor absorption units in settings with waste heat availability, while Stirling systems offer more precise temperature control but may incur higher maintenance expenses over time.

Cost Effectiveness and Economic Factors

Stirling cycle refrigeration systems generally feature higher initial capital costs due to precision engineering and advanced materials, but offer lower operational expenses through superior energy efficiency and reduced maintenance requirements. Absorption refrigeration systems demand less electrical energy by utilizing heat sources such as waste heat or solar energy, yielding cost savings in specific applications, though they often incur higher installation and material costs. Economic factors favor Stirling systems in environments with expensive electricity and where reliability minimizes downtime, whereas absorption units excel in settings with abundant low-cost thermal energy and where electricity costs are prohibitive.

Choosing the Right Refrigeration System

Choosing the right refrigeration system depends on application demands, energy sources, and efficiency requirements. Stirling cycle refrigeration offers high efficiency and precise temperature control, ideal for low-temperature applications but requires a consistent mechanical power supply. Absorption refrigeration excels in utilizing waste heat or solar energy with low electrical consumption, making it suitable for environments with limited electricity or where sustainability is prioritized.

Stirling cycle refrigeration Infographic

libterm.com

libterm.com