Direct Metal Laser Sintering (DMLS) is an advanced additive manufacturing technique that uses a high-powered laser to fuse metal powders layer by layer, creating complex and precise metal parts. This technology offers exceptional design flexibility and material efficiency, making it ideal for aerospace, medical, and automotive applications. Explore the rest of the article to discover how DMLS can transform Your manufacturing process with its innovative capabilities.

Table of Comparison

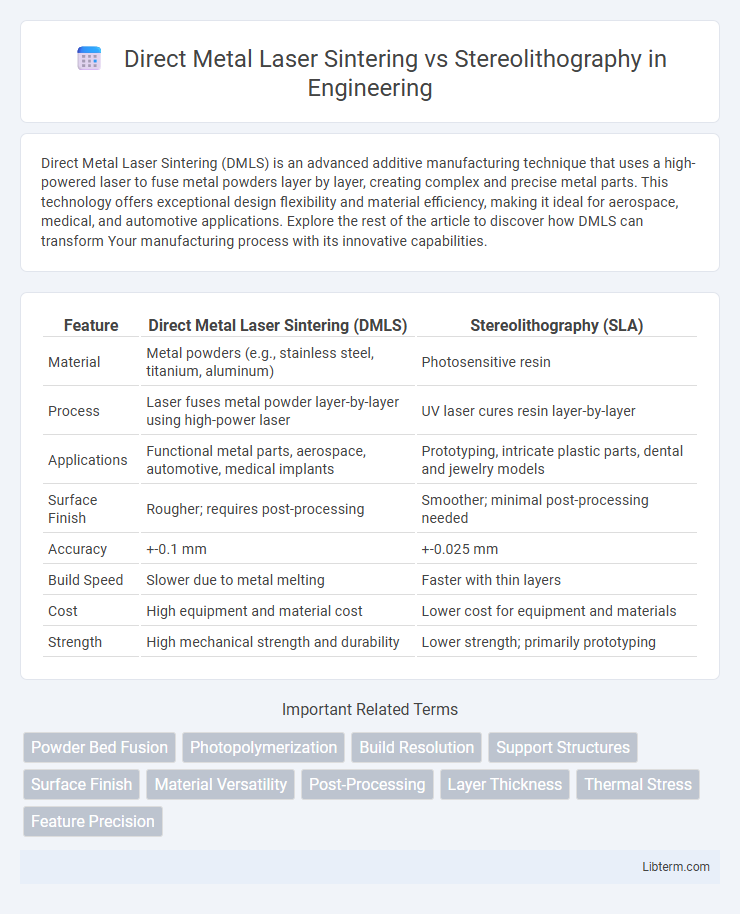

| Feature | Direct Metal Laser Sintering (DMLS) | Stereolithography (SLA) |

|---|---|---|

| Material | Metal powders (e.g., stainless steel, titanium, aluminum) | Photosensitive resin |

| Process | Laser fuses metal powder layer-by-layer using high-power laser | UV laser cures resin layer-by-layer |

| Applications | Functional metal parts, aerospace, automotive, medical implants | Prototyping, intricate plastic parts, dental and jewelry models |

| Surface Finish | Rougher; requires post-processing | Smoother; minimal post-processing needed |

| Accuracy | +-0.1 mm | +-0.025 mm |

| Build Speed | Slower due to metal melting | Faster with thin layers |

| Cost | High equipment and material cost | Lower cost for equipment and materials |

| Strength | High mechanical strength and durability | Lower strength; primarily prototyping |

Introduction to Direct Metal Laser Sintering and Stereolithography

Direct Metal Laser Sintering (DMLS) is an additive manufacturing process that uses a high-powered laser to fuse fine metal powders layer by layer, producing complex and high-strength metal parts ideal for aerospace, automotive, and medical industries. Stereolithography (SLA) employs a UV laser to cure liquid resin into solid plastic components with exceptional surface finish and detail, commonly used for prototyping, dental models, and intricate design parts. Both technologies offer precision and customization but differ significantly in materials, mechanics, and typical applications.

Core Principles of DMLS Technology

Direct Metal Laser Sintering (DMLS) utilizes a high-powered laser to selectively fuse fine metal powders layer by layer, creating complex, fully dense metal parts with high mechanical strength. The process relies on precise control of laser parameters, powder bed temperature, and scan strategies to ensure metallurgical bonding and minimize residual stresses. Unlike Stereolithography (SLA), which cures photopolymer resins using ultraviolet light, DMLS directly processes metal powders, enabling production of functional metal components with intricate geometries and material properties suitable for aerospace and medical applications.

Fundamentals of Stereolithography (SLA)

Stereolithography (SLA) uses a UV laser to cure liquid photopolymer resin layer-by-layer, achieving high precision and smooth surface finishes ideal for detailed prototypes. Unlike Direct Metal Laser Sintering (DMLS), which fuses metal powder using a laser, SLA operates exclusively with photosensitive resins, enabling complex geometries at a lower cost and faster speed. The curing process in SLA hinges on photopolymerization, where the ultraviolet laser solidifies resin selectively, offering exceptional accuracy for complex, non-metallic parts.

Material Capabilities: Metals vs. Photopolymers

Direct Metal Laser Sintering (DMLS) enables high-precision fabrication using a wide range of metal alloys, including titanium, stainless steel, and aluminum, offering superior mechanical properties and thermal resistance for industrial applications. Stereolithography (SLA) primarily utilizes photopolymer resins, delivering intricate detail and smooth surface finishes but with limited strength and heat resistance compared to metals. Material capabilities in DMLS support robust, load-bearing components, whereas SLA materials excel in prototyping and aesthetic applications where metal strength is not critical.

Precision and Surface Finish Comparison

Direct Metal Laser Sintering (DMLS) offers exceptional precision for complex metal parts, achieving layer thicknesses as fine as 20-40 microns, ideal for functional prototypes and end-use components. Stereolithography (SLA) excels in producing ultra-smooth surface finishes with resolutions up to 25 microns, making it preferable for detailed visual models and patterns requiring fine detail. While DMLS provides superior mechanical strength with moderately smooth surfaces, SLA delivers higher surface quality but lacks the material robustness of metal sintered parts.

Applications Across Industries

Direct Metal Laser Sintering (DMLS) excels in aerospace, automotive, and medical industries by producing complex metal parts with high strength and thermal resistance. Stereolithography (SLA) is widely used in prototyping, dental, and jewelry sectors for creating detailed, high-resolution plastic models with smooth surface finishes. Both technologies enable rapid product development but serve distinct purposes based on material properties and application requirements.

Production Speed and Scalability

Direct Metal Laser Sintering (DMLS) offers faster production speeds for complex metal parts due to its layer-by-layer sintering process, making it ideal for functional prototypes and low-volume manufacturing. Stereolithography (SLA) excels in producing high-detail plastic parts with smoother surfaces but generally requires longer post-processing times, which can slow overall production speed. Scalability in DMLS is enhanced by its ability to build multiple metal parts simultaneously on a larger build platform, whereas SLA scalability is limited by resin vat size and slower cure times, affecting batch production efficiency.

Cost Analysis: DMLS vs. SLA

Direct Metal Laser Sintering (DMLS) incurs higher initial and operational costs due to expensive metal powders, complex machinery, and longer post-processing compared to Stereolithography (SLA), which primarily uses photopolymer resins and simpler equipment. DMLS offers superior mechanical properties and metal part production, justifying its cost for aerospace and medical industries despite higher expenses. SLA remains more cost-effective for prototyping and low-volume plastic parts requiring fine detail and surface finish.

Advantages and Limitations of Each Method

Direct Metal Laser Sintering (DMLS) offers advantages such as high strength and durability due to its ability to produce fully dense metal parts with complex geometries, but it is limited by higher costs and longer post-processing times. Stereolithography (SLA) excels in producing high-resolution, smooth surface finishes with faster build speeds and lower material costs, yet it faces limitations in mechanical strength and thermal resistance compared to metal-based methods. Choosing between DMLS and SLA depends on the application requirements for material properties, precision, and production scale.

Choosing the Right 3D Printing Technology

Direct Metal Laser Sintering (DMLS) excels in producing durable, functional metal parts with complex geometries by fusing metal powder layer by layer using a laser, making it ideal for aerospace and automotive industries requiring high strength and heat resistance. Stereolithography (SLA) utilizes a UV laser to cure photopolymer resin, delivering highly detailed, smooth prototypes and parts suitable for applications demanding fine surface finishes and intricate designs such as jewelry and medical models. Choosing the right 3D printing technology depends on material requirements, mechanical properties, detail resolution, and end-use application, where DMLS is preferred for metal strength and durability, while SLA suits precision and aesthetic quality.

Direct Metal Laser Sintering Infographic

libterm.com

libterm.com