Stiffness refers to the resistance of an object or material to deformation when subjected to an applied force. It plays a crucial role in engineering, biomechanics, and material science, influencing how structures and components respond under load. Explore the full article to understand how stiffness impacts your designs and applications.

Table of Comparison

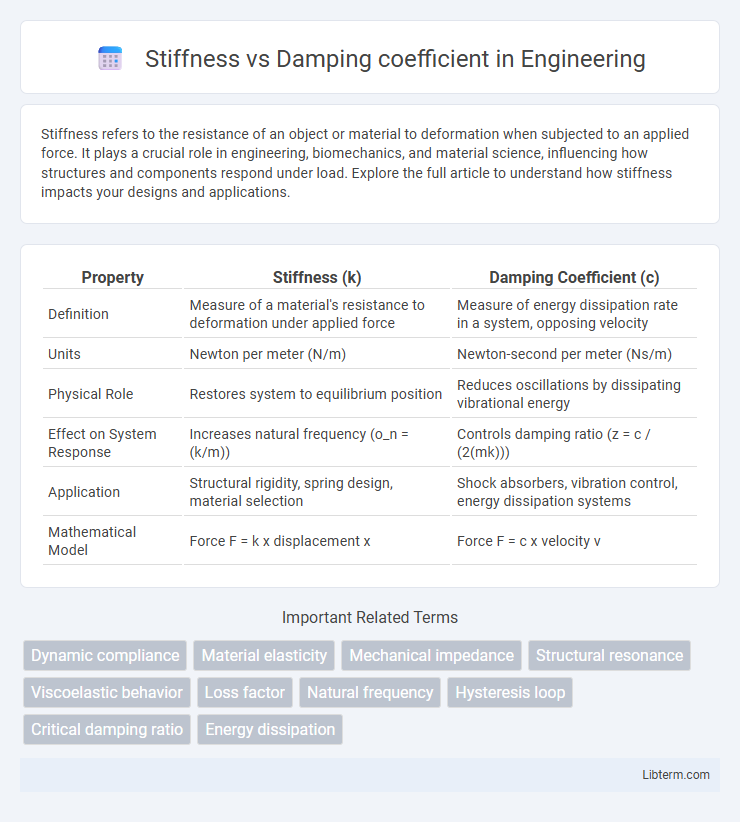

| Property | Stiffness (k) | Damping Coefficient (c) |

|---|---|---|

| Definition | Measure of a material's resistance to deformation under applied force | Measure of energy dissipation rate in a system, opposing velocity |

| Units | Newton per meter (N/m) | Newton-second per meter (Ns/m) |

| Physical Role | Restores system to equilibrium position | Reduces oscillations by dissipating vibrational energy |

| Effect on System Response | Increases natural frequency (o_n = (k/m)) | Controls damping ratio (z = c / (2(mk))) |

| Application | Structural rigidity, spring design, material selection | Shock absorbers, vibration control, energy dissipation systems |

| Mathematical Model | Force F = k x displacement x | Force F = c x velocity v |

Understanding Stiffness and Damping Coefficient

Stiffness represents a material or system's resistance to deformation under applied force, typically measured in units of force per displacement (N/m). The damping coefficient quantifies energy dissipation within a system during motion, expressed in units like Ns/m, and influences oscillation reduction and system stability. Understanding these parameters is crucial for designing mechanical systems with desired dynamic responses and vibration control.

Core Principles: Stiffness in Mechanical Systems

Stiffness in mechanical systems quantifies an object's resistance to deformation when subjected to force, typically represented by the spring constant \( k \) in Hooke's Law \( F = kx \). Higher stiffness values indicate greater force required for a given displacement, directly influencing system stability and vibration frequency. The damping coefficient, in contrast, governs energy dissipation and controls oscillation amplitude without affecting the system's inherent stiffness characteristics.

The Role of Damping Coefficient Explained

The damping coefficient plays a crucial role in controlling the oscillatory motion of mechanical systems by dissipating energy and reducing vibration amplitude over time. Unlike stiffness, which determines the system's resistance to deformation and affects natural frequency, the damping coefficient influences the rate at which oscillations decay, thereby enhancing system stability and comfort. Optimizing the damping coefficient is essential for preventing excessive vibrations and ensuring efficient performance in applications ranging from automotive suspensions to structural engineering.

Mathematical Relationship: Stiffness vs Damping

The mathematical relationship between stiffness (k) and damping coefficient (c) is commonly analyzed through the equation of motion for a damped harmonic oscillator: m*x'' + c*x' + k*x = 0. Stiffness directly relates to the system's restoring force, while the damping coefficient governs energy dissipation and affects system response time and oscillation decay. The critical damping condition occurs when c = 2(mk), representing the threshold between overdamped and underdamped responses.

Real-World Applications of Stiffness and Damping

Stiffness and damping coefficients critically influence the performance of mechanical systems by controlling vibration and stability in real-world applications such as automotive suspension and aerospace structures. High stiffness ensures structural rigidity, minimizing deformation under load, while optimal damping dissipates energy, reducing oscillations and enhancing comfort and safety. Engineering designs balance these parameters to improve durability and dynamic response in products like bridges, machinery, and consumer electronics.

Impact on System Dynamics and Vibration Control

Stiffness directly influences the natural frequency of a system, determining its oscillatory response and resilience to deformation under dynamic loads. The damping coefficient governs energy dissipation, reducing amplitude and controlling vibration decay rates, thereby preventing resonant amplification and promoting system stability. Optimizing the balance between stiffness and damping is crucial for efficient vibration control and enhanced dynamic performance in mechanical and structural systems.

Comparing Effects: Stiffness vs Damping in Design

Stiffness directly influences a system's natural frequency and ability to resist deformation under load, while the damping coefficient controls energy dissipation and reduces oscillations. Higher stiffness increases the system's rigidity and resonance frequency, whereas increased damping minimizes amplitude and stabilizes motion by dissipating vibrational energy. Optimal design balances stiffness and damping to achieve desired dynamic performance, ensuring structural integrity and comfort under operational conditions.

Testing and Measurement Techniques

Stiffness and damping coefficients are critical parameters in dynamic system analysis, typically measured using methods such as modal testing, impact hammer testing, and shaker excitation. Frequency response functions (FRFs) obtained from accelerometer data enable precise calculation of stiffness through natural frequency identification and damping coefficients via logarithmic decrement or half-power bandwidth methods. Advanced techniques like laser Doppler vibrometry and finite element model updating enhance measurement accuracy by providing detailed displacement and velocity data under controlled excitation.

Optimizing Systems: Balancing Stiffness and Damping

Optimizing systems requires a precise balance between stiffness and damping coefficients to enhance performance and durability. Higher stiffness increases system rigidity and natural frequency, reducing deflection under load, while appropriate damping dissipates vibrational energy, minimizing oscillations and preventing resonance. Achieving the optimal ratio improves stability, reduces noise, and extends the lifespan of mechanical and structural components.

Future Trends and Innovations in Stiffness-Damping Analysis

Future trends in stiffness-damping analysis emphasize advanced materials with tunable stiffness and adaptive damping properties, enabling real-time structural health monitoring and optimization. Innovations in machine learning and AI-driven modeling enhance predictive accuracy for complex systems, facilitating smarter designs in aerospace and automotive industries. Integration of nano-engineered composites and metamaterials promises revolutionized vibration control and energy dissipation mechanisms.

Stiffness Infographic

libterm.com

libterm.com