Cross flow refers to the movement of air or fluid perpendicular to a surface or through a system, commonly used in HVAC, automotive radiators, and industrial processes to enhance heat exchange efficiency. This method ensures optimal temperature regulation by maximizing contact between the medium and the surface, reducing energy consumption and improving performance. Discover how cross flow technology can benefit your applications by exploring the detailed insights in the rest of this article.

Table of Comparison

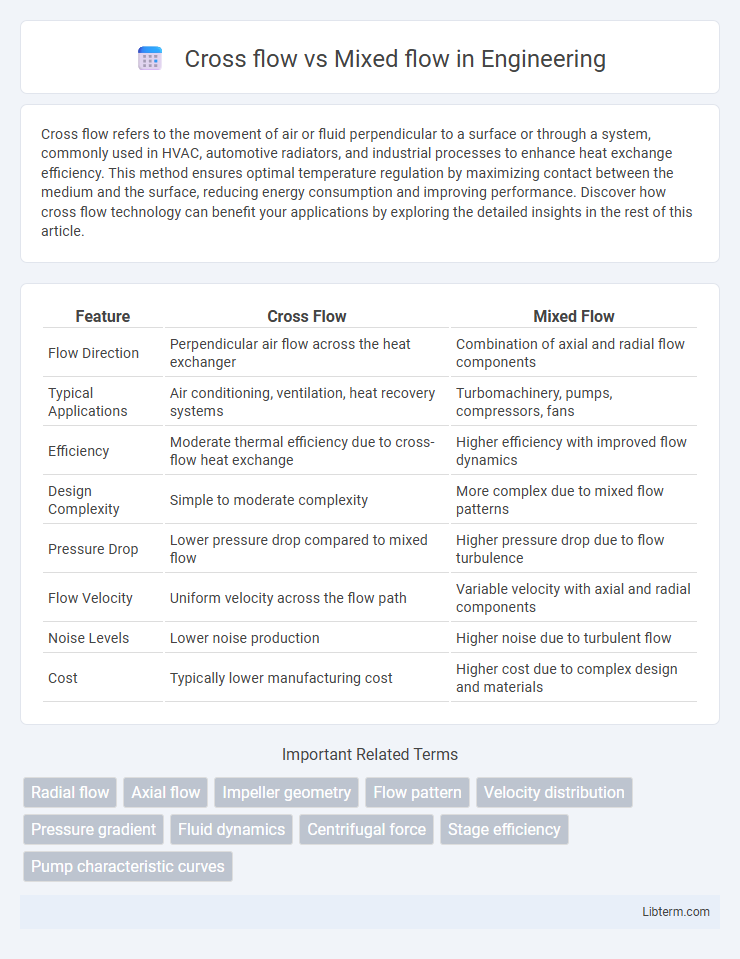

| Feature | Cross Flow | Mixed Flow |

|---|---|---|

| Flow Direction | Perpendicular air flow across the heat exchanger | Combination of axial and radial flow components |

| Typical Applications | Air conditioning, ventilation, heat recovery systems | Turbomachinery, pumps, compressors, fans |

| Efficiency | Moderate thermal efficiency due to cross-flow heat exchange | Higher efficiency with improved flow dynamics |

| Design Complexity | Simple to moderate complexity | More complex due to mixed flow patterns |

| Pressure Drop | Lower pressure drop compared to mixed flow | Higher pressure drop due to flow turbulence |

| Flow Velocity | Uniform velocity across the flow path | Variable velocity with axial and radial components |

| Noise Levels | Lower noise production | Higher noise due to turbulent flow |

| Cost | Typically lower manufacturing cost | Higher cost due to complex design and materials |

Introduction to Cross Flow and Mixed Flow

Cross flow and mixed flow refer to distinct fluid dynamics patterns in engineering applications. Cross flow involves fluid moving perpendicular to a reference surface, optimizing heat exchange and filtration processes by maintaining consistent fluid distribution. Mixed flow combines axial and radial movement, enhancing fluid velocity and pressure management in pumps and turbines for improved efficiency.

Principles of Cross Flow Design

Cross flow design operates on the principle where fluid flows perpendicular to the surface, enabling efficient heat or mass transfer through a consistent movement across channels. This design maximizes surface area exposure and maintains steady temperature gradients, making it ideal for cooling towers, heat exchangers, and filtration systems. The key advantage lies in its ability to handle variable flow rates with lower pressure drops compared to mixed flow, which combines axial and radial components for enhanced velocity but higher energy consumption.

Principles of Mixed Flow Design

Mixed flow design combines radial and axial flow principles to optimize fluid movement and increase pump efficiency by using a diagonal impeller that directs fluid both outward and along the shaft axis. This design achieves higher pressure heads than pure axial flow and greater flow rates than radial flow, making it suitable for applications requiring moderate head and high flow. The impeller shape and channel geometry are critical in controlling the velocity components, minimizing energy loss, and improving aerodynamic performance in mixed flow pumps.

Key Differences: Cross Flow vs Mixed Flow

Cross flow and mixed flow fans differ primarily in airflow direction and blade design. Cross flow fans move air perpendicular to the axis of rotation, creating a wide, uniform airflow ideal for ventilation and cooling applications. Mixed flow fans combine axial and centrifugal flow principles, producing higher pressure and airflow efficiency suitable for HVAC systems and industrial processes.

Efficiency Comparison

Cross flow fans exhibit moderate efficiency by directing air perpendicular to the impeller, creating uniform airflow patterns suitable for low-pressure applications, whereas mixed flow fans combine axial and radial flow characteristics to achieve higher static pressure and improved efficiency in medium to high-pressure systems. Mixed flow fans typically outperform cross flow fans in energy efficiency due to their optimized aerodynamic design, which reduces turbulence and power consumption. Efficiency metrics for mixed flow fans often reach above 70%, compared to the 50-60% range commonly observed in cross flow fan applications.

Applications in Industry

Cross flow and mixed flow fans serve distinct industrial applications based on airflow patterns and efficiency requirements. Cross flow fans, known for uniform airflow across their length, are widely used in HVAC systems, cooling electronic equipment, and air curtains where consistent air distribution is critical. Mixed flow fans combine axial and centrifugal flow principles, offering higher pressure and flow rates, making them ideal for industrial ventilation, dust collection, and process cooling in manufacturing plants and chemical industries.

Performance Under Various Conditions

Cross flow fans deliver consistent airflow and pressure, making them suitable for applications requiring uniform cooling or ventilation across wide areas. Mixed flow fans combine axial and centrifugal designs to achieve higher pressure and flow rates, excelling in environments with variable static pressure demands. Performance under diverse conditions shows cross flow fans maintain steady operation at low noise levels, while mixed flow fans provide enhanced efficiency and adaptability in industrial settings with fluctuating airflow requirements.

Advantages of Cross Flow Systems

Cross flow systems offer superior heat transfer efficiency due to the perpendicular arrangement of fluid streams, enabling effective temperature gradients and consistent performance. These systems typically require less maintenance and exhibit lower clogging risks compared to mixed flow designs because fluid paths remain more streamlined. Enhanced durability and energy savings result from reduced pressure drops, making cross flow heat exchangers ideal for industrial cooling and air handling applications.

Benefits of Mixed Flow Systems

Mixed flow systems offer enhanced energy efficiency by combining axial and radial flow characteristics, resulting in improved pressure recovery and reduced power consumption. These systems provide greater versatility in handling varying flow rates and pressures, making them ideal for industrial applications requiring consistent performance. The ability to maintain stable flow with reduced turbulence also leads to longer equipment lifespan and lower maintenance costs.

Choosing the Right Flow Type for Your Needs

Selecting between cross flow and mixed flow fans depends on specific airflow requirements and space constraints. Cross flow fans provide uniform airflow across a wide area, ideal for evenly cooling electronics or HVAC systems, while mixed flow fans combine axial and centrifugal features, delivering higher pressure and efficiency for ventilation in confined spaces. Evaluating factors such as airflow volume, static pressure needs, noise levels, and installation space ensures the optimal fan type aligns with your ventilation or cooling application.

Cross flow Infographic

libterm.com

libterm.com