In-situ testing offers real-time evaluation of materials and structures directly at their location, providing accurate data that lab tests might miss. This method helps identify potential issues early, ensuring the integrity and safety of construction projects. Discover how in-situ testing can improve your project's reliability by continuing to read the rest of the article.

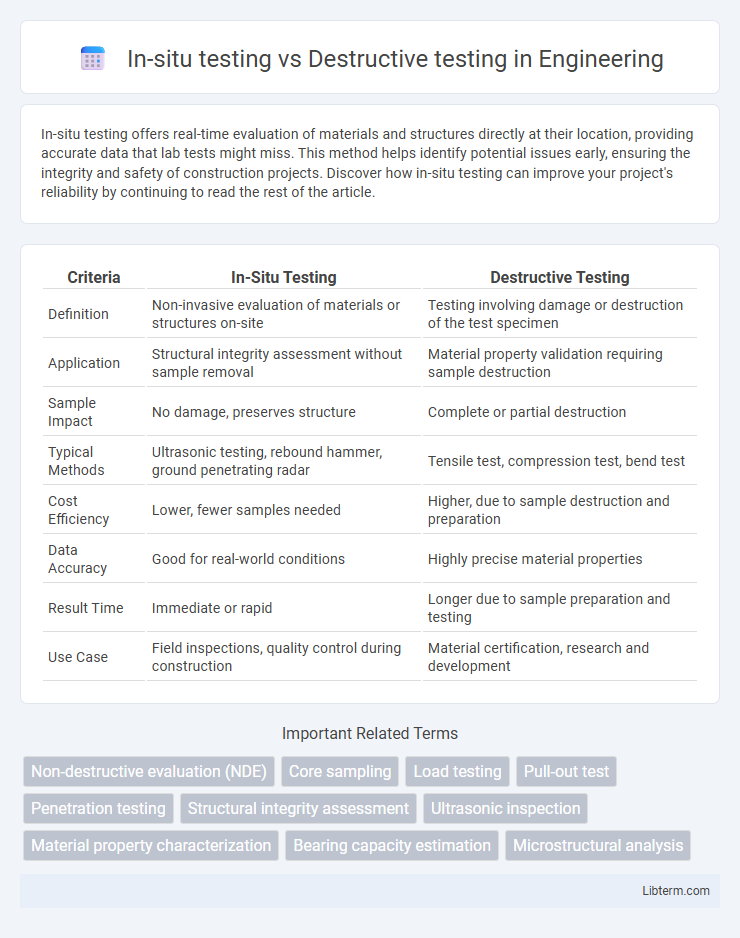

Table of Comparison

| Criteria | In-Situ Testing | Destructive Testing |

|---|---|---|

| Definition | Non-invasive evaluation of materials or structures on-site | Testing involving damage or destruction of the test specimen |

| Application | Structural integrity assessment without sample removal | Material property validation requiring sample destruction |

| Sample Impact | No damage, preserves structure | Complete or partial destruction |

| Typical Methods | Ultrasonic testing, rebound hammer, ground penetrating radar | Tensile test, compression test, bend test |

| Cost Efficiency | Lower, fewer samples needed | Higher, due to sample destruction and preparation |

| Data Accuracy | Good for real-world conditions | Highly precise material properties |

| Result Time | Immediate or rapid | Longer due to sample preparation and testing |

| Use Case | Field inspections, quality control during construction | Material certification, research and development |

Introduction to In-Situ and Destructive Testing

In-situ testing evaluates material properties or structural integrity directly at the site without causing damage, providing real-time data crucial for immediate decision-making. Destructive testing involves subjecting samples to controlled conditions until failure, offering detailed insights into mechanical properties such as tensile strength and ductility through methods like tensile, impact, and hardness tests. These contrasting approaches balance the need for non-invasive assessment with comprehensive material characterization in engineering and quality control.

Fundamental Principles of In-Situ Testing

In-situ testing evaluates material properties and soil conditions directly at the site without causing permanent damage, enabling real-time assessment under natural conditions. These tests rely on fundamental principles such as measuring soil resistance, deformation, and strength by applying controlled forces through probes, cones, or plates inserted into the ground. The non-destructive nature of in-situ testing offers accurate representation of subsurface conditions, contrasting with destructive testing which requires sample extraction and laboratory analysis, potentially altering material characteristics.

Key Concepts in Destructive Testing

Destructive testing involves physically altering or damaging materials to evaluate their mechanical properties, such as tensile strength, hardness, and impact resistance. Key concepts include sample preparation, controlled loading conditions, and failure analysis to determine material behavior under stress. This testing method provides accurate data for quality control and material performance but results in the loss of the tested specimen.

Types of In-Situ Testing Methods

In-situ testing methods include Standard Penetration Test (SPT), Cone Penetration Test (CPT), and Plate Load Test, each providing real-time soil properties assessment without damaging the site. These tests measure parameters such as soil resistance, bearing capacity, and deformation characteristics essential for geotechnical engineering. Unlike destructive testing, in-situ methods preserve site integrity while offering accurate soil behavior data under natural conditions.

Common Destructive Testing Techniques

Common destructive testing techniques include tensile testing, impact testing, and hardness testing, which evaluate material properties by purposely damaging samples to assess strength, ductility, and toughness. These methods provide precise data on mechanical behavior under different stresses, essential for quality control and safety assurance in manufacturing and construction. In contrast, in-situ testing measures material performance directly within structures without causing irreversible damage, offering real-time condition assessments.

Comparative Analysis: Accuracy and Reliability

In-situ testing provides real-time data on material or structural integrity without causing damage, ensuring high reliability in operational conditions. Destructive testing offers precise measurement of material properties through sample failure, delivering highly accurate but non-repeatable results due to specimen destruction. The comparative accuracy of in-situ testing hinges on environmental variables and sensor quality, while destructive testing maintains consistent accuracy by directly assessing material limits under controlled conditions.

Impact on Structural Integrity and Safety

In-situ testing preserves structural integrity by evaluating materials and components without causing damage, ensuring safety through real-time condition assessment and reducing the risk of weakening critical elements. Destructive testing, though highly accurate for understanding material limits and failure modes, compromises structural safety by physically damaging or destroying samples, making it unsuitable for assessing in-service structures. Balancing these approaches enables engineers to maintain structural integrity while gaining comprehensive safety data critical for maintenance and design decisions.

Cost and Time Considerations

In-situ testing typically offers lower costs and faster results compared to destructive testing, as it avoids the need for sample extraction and extensive laboratory analysis. Destructive testing, while more expensive and time-consuming due to specimen preparation and post-test restoration, provides higher accuracy and detailed material properties. Project budgets and deadlines often influence the choice, with in-situ testing preferred for preliminary assessments and destructive testing for critical structural evaluations.

Practical Applications in Industry

In-situ testing offers real-time evaluation of materials or structures on-site, minimizing downtime and preserving integrity, making it ideal for quality control in construction, aerospace, and civil engineering projects. Destructive testing, involving material sample failure, provides detailed insights into mechanical properties and structural limits, crucial for product certification and safety validation in automotive manufacturing and metallurgy. Industries often combine both methods to optimize performance assessment, balancing immediate operational feedback with comprehensive lab-based data.

Choosing the Right Testing Method

In-situ testing offers real-time assessment of material properties and structural integrity without damaging the specimen, making it ideal for ongoing monitoring and preservation efforts. Destructive testing provides comprehensive data on material limits and failure modes through controlled damage, crucial for understanding performance under extreme conditions. Selecting the appropriate method depends on project goals, budget constraints, and whether preserving the tested item is essential.

In-situ testing Infographic

libterm.com

libterm.com