Drawing enhances your creativity and improves hand-eye coordination by allowing you to express ideas visually. It fosters mindfulness and reduces stress through focused practice. Explore the rest of the article to discover essential drawing techniques and tips to elevate your skills.

Table of Comparison

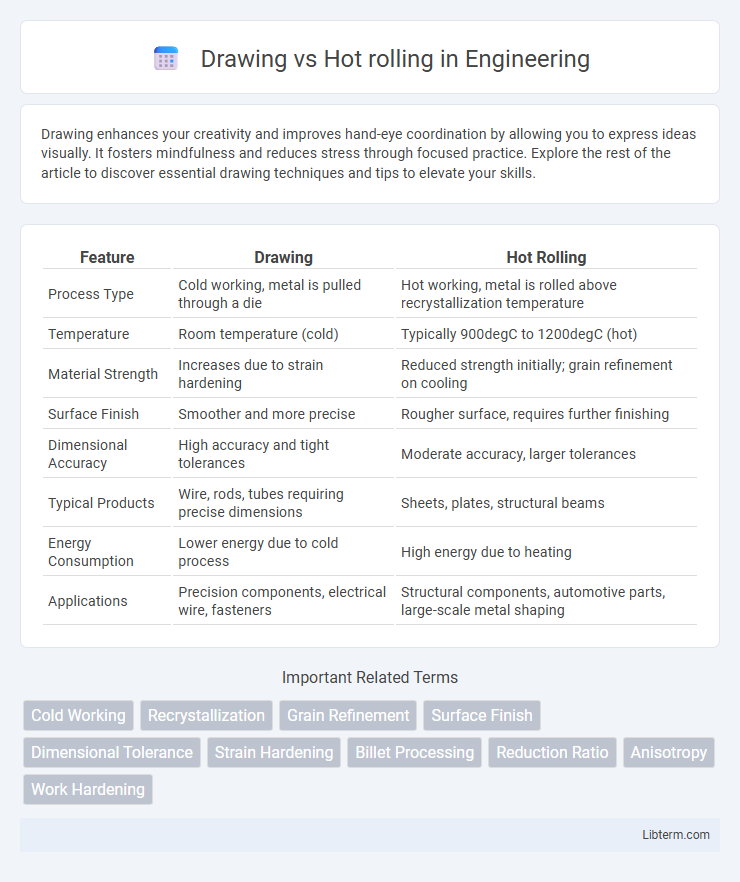

| Feature | Drawing | Hot Rolling |

|---|---|---|

| Process Type | Cold working, metal is pulled through a die | Hot working, metal is rolled above recrystallization temperature |

| Temperature | Room temperature (cold) | Typically 900degC to 1200degC (hot) |

| Material Strength | Increases due to strain hardening | Reduced strength initially; grain refinement on cooling |

| Surface Finish | Smoother and more precise | Rougher surface, requires further finishing |

| Dimensional Accuracy | High accuracy and tight tolerances | Moderate accuracy, larger tolerances |

| Typical Products | Wire, rods, tubes requiring precise dimensions | Sheets, plates, structural beams |

| Energy Consumption | Lower energy due to cold process | High energy due to heating |

| Applications | Precision components, electrical wire, fasteners | Structural components, automotive parts, large-scale metal shaping |

Introduction to Metal Forming Techniques

Drawing and hot rolling are fundamental metal forming techniques used to shape metals by plastic deformation. Drawing involves pulling a metal through a die to reduce its cross-sectional area with high precision, typically used for wires and tubes, while hot rolling processes metal above its recrystallization temperature to produce large sheets or structural shapes efficiently. These methods balance material properties like strength, ductility, and surface finish, critical in applications ranging from automotive components to construction materials.

Overview of Drawing and Hot Rolling Processes

Drawing is a metal forming process where a metal blank is pulled through a die to reduce its diameter and increase its length, commonly used for producing wires, rods, and tubes with improved surface finish and dimensional accuracy. Hot rolling involves deforming metal above its recrystallization temperature by passing it through rollers, which refines the grain structure, enhances mechanical properties, and allows large-scale shaping of metal slabs or billets into sheets, plates, or structural shapes. Both processes play crucial roles in metal manufacturing, with drawing specializing in precise dimensional control and hot rolling enabling bulk shaping and microstructural improvements.

Key Differences Between Drawing and Hot Rolling

Drawing involves pulling a metal stock through a die to reduce its diameter, producing precise dimensions and smooth surface finishes, whereas hot rolling processes metal above recrystallization temperature to shape and thicken it, resulting in coarser surface textures and less dimensional accuracy. Drawing typically enhances material strength through work hardening, while hot rolling improves ductility by refining the grain structure at elevated temperatures. The key differences also include temperature usage--cold temperatures for drawing and high temperatures for hot rolling--which affect mechanical properties and dimensional tolerances distinctly.

Material Suitability: When to Choose Drawing or Hot Rolling

Drawing is ideal for materials with high tensile strength and requires precise dimensional control, commonly used for metals like copper, aluminum, and stainless steel. Hot rolling suits ductile materials such as carbon steel and low alloy steels, facilitating large-scale deformation at elevated temperatures for improved grain structure. Choose drawing for intricate shapes and thin cross-sections, while hot rolling is preferable for bulkier forms and enhanced mechanical properties.

Equipment and Tooling Required

Drawing processes require precise dies and drawing benches or presses designed to pull metal through a die, emphasizing high tensile strength tools to maintain shape accuracy. Hot rolling utilizes heavy-duty rollers and furnaces to heat metals before deformation, necessitating robust rolling mills and temperature control systems to handle material expansion and achieve desired thickness. Tooling in hot rolling is subject to extreme thermal stress, requiring durable materials resistant to high temperatures, whereas drawing tools focus on wear resistance and precision shaping.

Surface Finish and Dimensional Accuracy

Drawing provides a superior surface finish due to its controlled deformation process, resulting in smoother and cleaner surfaces compared to hot rolling. The dimensional accuracy in drawing is significantly higher as it allows precise control over the final dimensions and tighter tolerances. Hot rolling, by contrast, often yields rougher surfaces and less exact dimensions owing to thermal expansion and scale formation during the high-temperature process.

Mechanical Properties Achieved

Drawing enhances tensile strength and surface finish by inducing strain hardening through plastic deformation, resulting in improved dimensional accuracy and hardness. Hot rolling produces components with refined grain structures, offering good ductility and toughness due to recrystallization at elevated temperatures. While drawing yields superior mechanical strength, hot rolling provides better formability and resistance to cracking under impact.

Typical Industrial Applications

Drawing is commonly used in the production of wires, cables, and precision metal components requiring tight tolerances and smooth surface finishes. Hot rolling is favored for manufacturing large structural steel shapes, such as beams, rails, and plates used in construction and heavy machinery. Industries relying on high-strength materials, like automotive and aerospace, often combine both processes to optimize mechanical properties and dimensional accuracy.

Cost and Efficiency Considerations

Hot rolling generally offers lower production costs due to higher throughput and less energy-intensive processing compared to drawing. Drawing processes, while more precise for producing complex shapes and tighter tolerances, incur higher operational costs from slower speeds and additional finishing steps. Efficiency in hot rolling benefits from continuous operation and bulk material handling, whereas drawing may require multiple passes, increasing labor and energy consumption.

Summary: Selecting the Right Process

Drawing offers precise dimensional control and improved surface finish, ideal for applications requiring tight tolerances and fine details. Hot rolling provides enhanced ductility and reduced residual stress, making it suitable for large-scale production of billets, sheets, and structural components. Choosing between drawing and hot rolling depends on the required mechanical properties, surface quality, and production volume.

Drawing Infographic

libterm.com

libterm.com