Automatic welding enhances production efficiency by consistently delivering precise, high-quality welds with minimal human intervention. This technology reduces errors and increases safety, making it ideal for industries requiring repetitive and complex welding tasks. Discover how automatic welding can transform your manufacturing process by exploring the full article.

Table of Comparison

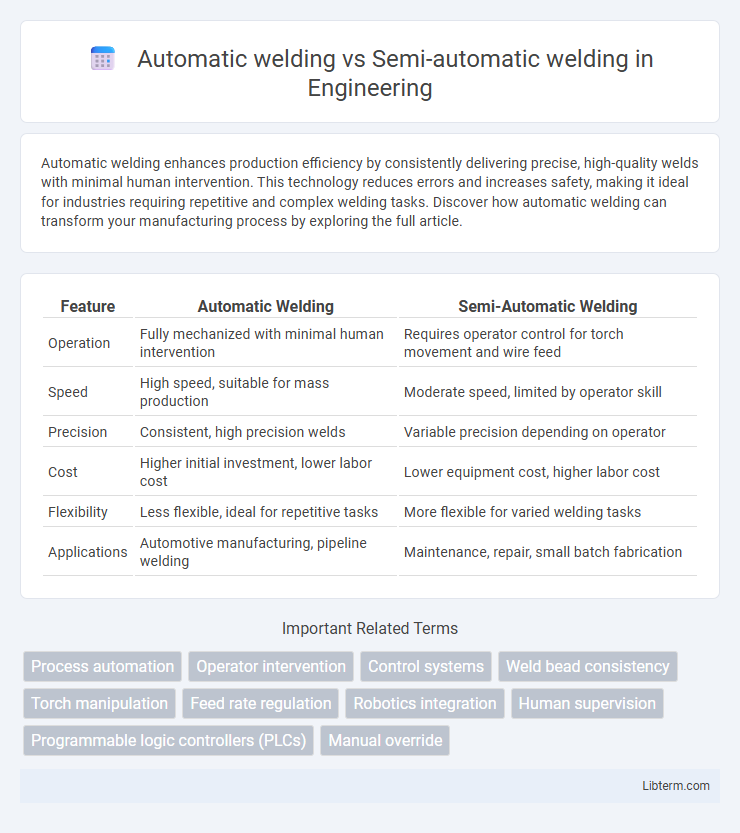

| Feature | Automatic Welding | Semi-Automatic Welding |

|---|---|---|

| Operation | Fully mechanized with minimal human intervention | Requires operator control for torch movement and wire feed |

| Speed | High speed, suitable for mass production | Moderate speed, limited by operator skill |

| Precision | Consistent, high precision welds | Variable precision depending on operator |

| Cost | Higher initial investment, lower labor cost | Lower equipment cost, higher labor cost |

| Flexibility | Less flexible, ideal for repetitive tasks | More flexible for varied welding tasks |

| Applications | Automotive manufacturing, pipeline welding | Maintenance, repair, small batch fabrication |

Introduction to Automatic and Semi-Automatic Welding

Automatic welding utilizes programmable machinery to perform welding tasks with minimal human intervention, enhancing consistency and speed in industrial applications. Semi-automatic welding requires operator control over the welding gun while the wire feed or shielding gas is mechanically regulated, allowing for flexibility and precision in complex jobs. Both methods optimize productivity but differ in the extent of automation and operator involvement.

Defining Automatic Welding

Automatic welding involves a fully mechanized process where the welding machine controls all parameters such as speed, feed, and temperature without human intervention, ensuring consistent weld quality and high production rates. In contrast, semi-automatic welding requires an operator to guide the welding torch while the machine regulates the welding arc and feed, balancing control and automation. Automatic welding systems excel in repetitive, high-volume industrial applications like pipeline construction and automotive manufacturing due to their precision and efficiency.

Explaining Semi-Automatic Welding

Semi-automatic welding involves the use of a welding gun operated manually by the welder, while the welding wire feeder is automatic, providing a steady supply of filler metal for consistent welds. This method offers greater control over the welding process, making it ideal for intricate and precision tasks where contour and penetration need fine adjustments. Semi-automatic welding is commonly used in industries such as automotive and fabrication, balancing efficiency and operator skill to achieve high-quality results.

Key Differences Between Automatic and Semi-Automatic Welding

Automatic welding uses pre-programmed robotic systems to perform welds with minimal human intervention, ensuring consistent precision and higher production rates. Semi-automatic welding requires a skilled operator to manually control the welding gun and feed the filler material, providing greater flexibility for complex or variable welds but at the cost of slower throughput. Key differences include the level of automation, operator involvement, efficiency, and suitability for repetitive versus customized welding tasks.

Equipment and Technology Requirements

Automatic welding requires advanced robotic systems and sophisticated control units capable of performing welding tasks with minimal human intervention, ensuring consistent precision and high production rates. Semi-automatic welding involves handheld equipment such as MIG or TIG welders that rely on operator skill to control the weld pool and electrode movement, offering greater flexibility but lower automation. Equipment costs for automatic welding are significantly higher due to the integration of sensors, actuators, and programmable logic controllers, while semi-automatic setups are more affordable and easier to deploy in diverse work environments.

Process Control and Operator Involvement

Automatic welding offers precise process control through computer-programmed sequences that ensure consistent weld quality with minimal human intervention. Semi-automatic welding requires constant operator input to regulate the welding speed, electrode feed, and positioning, introducing variability based on skill level. The reduced operator involvement in automatic welding results in higher repeatability and efficiency, while semi-automatic processes provide greater flexibility for complex or customized welds.

Applications and Industry Use Cases

Automatic welding is extensively used in high-volume manufacturing sectors such as automotive, aerospace, and pipeline construction due to its ability to deliver consistent, high-quality welds with minimal human intervention. Semi-automatic welding finds broad application in construction, shipbuilding, and maintenance industries where flexibility and operator control are essential for handling complex, variable welding tasks. Both technologies optimize productivity; automatic welding excels in repetitive, large-scale projects, while semi-automatic welding provides adaptability for customized or on-site fabrications.

Advantages of Automatic Welding

Automatic welding offers superior consistency and precision, significantly reducing human error and increasing production efficiency. It enables continuous operation with minimal supervision, cutting labor costs and boosting throughput for large-scale manufacturing. Enhanced quality control through programmable parameters ensures repeatable welds that meet stringent industry standards.

Benefits of Semi-Automatic Welding

Semi-automatic welding offers precise control over the welding process, allowing operators to adjust variables such as speed, angle, and filler material, resulting in higher-quality welds for complex or customized projects. It enhances flexibility by enabling welders to adapt to varying work conditions and materials, reducing waste and rework. This method improves efficiency and reduces fatigue, as operators handle only part of the process while maintaining critical control over weld integrity.

Choosing the Right Welding Method: Key Considerations

Choosing the right welding method depends on factors such as project complexity, production volume, and budget constraints. Automatic welding offers high precision and consistency ideal for large-scale, repetitive tasks, while semi-automatic welding provides greater flexibility and control for varied or smaller projects. Evaluating the material type, welding environment, and operator skill level is essential for optimizing quality and efficiency in manufacturing processes.

Automatic welding Infographic

libterm.com

libterm.com