Stress impacts both mental and physical health by triggering the release of hormones that affect body functions and emotional well-being. Managing stress effectively involves techniques such as mindfulness, exercise, and proper sleep habits that can improve resilience and reduce symptoms. Discover practical strategies to regain control and enhance Your overall quality of life by reading the rest of the article.

Table of Comparison

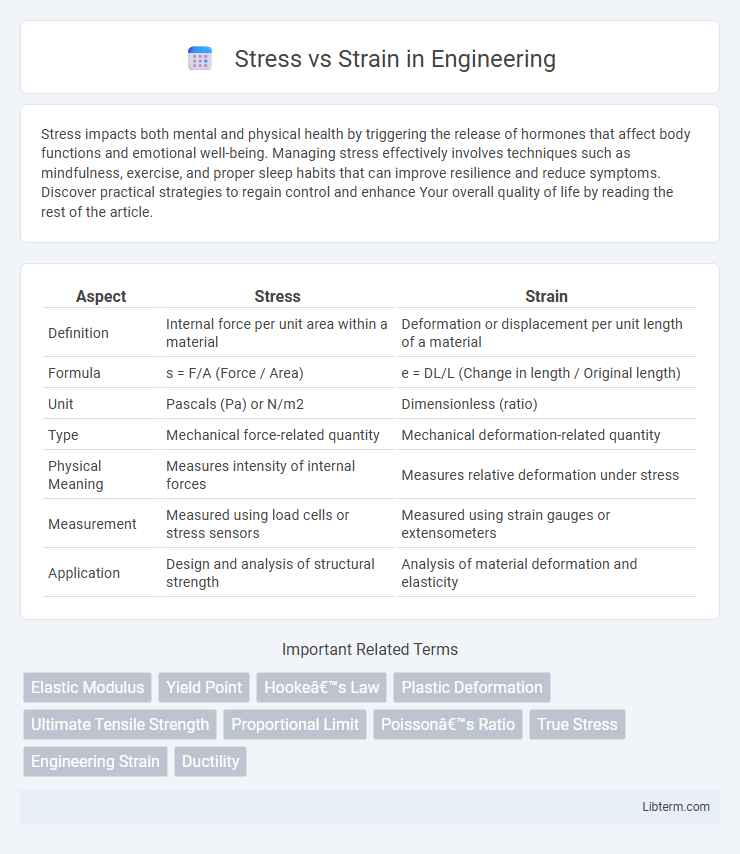

| Aspect | Stress | Strain |

|---|---|---|

| Definition | Internal force per unit area within a material | Deformation or displacement per unit length of a material |

| Formula | s = F/A (Force / Area) | e = DL/L (Change in length / Original length) |

| Unit | Pascals (Pa) or N/m2 | Dimensionless (ratio) |

| Type | Mechanical force-related quantity | Mechanical deformation-related quantity |

| Physical Meaning | Measures intensity of internal forces | Measures relative deformation under stress |

| Measurement | Measured using load cells or stress sensors | Measured using strain gauges or extensometers |

| Application | Design and analysis of structural strength | Analysis of material deformation and elasticity |

Understanding Stress and Strain: Core Definitions

Stress represents the internal force per unit area within materials that arises from externally applied forces, expressed in Pascals (Pa). Strain measures the deformation or displacement of a material relative to its original length, defined as a dimensionless ratio or percentage. Understanding these core definitions is essential for analyzing material behavior under load conditions in engineering and physics.

The Science Behind Stress: Types and Causes

Stress in materials refers to the internal force per unit area arising from external loads, categorized into tensile, compressive, and shear stress based on the direction of the applied force. Causes of stress include mechanical forces such as tension, compression, torsion, and bending, as well as thermal expansion and contraction leading to residual stress within structures. Understanding the microscopic behavior of atoms and dislocations under stress elucidates material deformation and failure mechanisms essential for engineering applications.

Strain Explained: Deformation and Its Measurement

Strain measures the deformation of a material relative to its original length, expressed as a dimensionless ratio or percentage. It quantifies how much a material stretches, compresses, or twists under applied stress, indicating changes in shape or size. Accurate strain measurement techniques include extensometers, strain gauges, and digital image correlation, essential for material testing and structural analysis.

Key Differences Between Stress and Strain

Stress measures the internal force per unit area within a material caused by externally applied loads, expressed in units like pascals (Pa). Strain quantifies the deformation or displacement of the material relative to its original length, a dimensionless ratio often represented as e. The key difference lies in stress being a force-related physical quantity, while strain is a measure of the resultant change in shape or size of the material.

Types of Stress in Materials

Normal stress occurs when a force is applied perpendicular to the surface of a material, causing either tensile or compressive deformation. Shear stress acts parallel to the surface, leading to sliding or distortion within the material's structure. Understanding these stress types is crucial for analyzing how materials respond under various loading conditions and ensuring structural integrity.

Varieties of Strain: Elastic vs Plastic

Elastic strain occurs when a material deforms under stress but returns to its original shape once the load is removed, demonstrating reversible deformation. Plastic strain, in contrast, involves permanent deformation where the material changes shape irreversibly after exceeding its elastic limit. Understanding the distinction between elastic and plastic strain is crucial for predicting material behavior under various stress conditions and designing structures that can withstand specific loads without failure.

Stress-Strain Curve: What It Reveals

The stress-strain curve reveals critical material properties such as elastic limit, yield strength, tensile strength, and ductility. This graphical representation shows how a material deforms under applied stress, distinguishing between elastic deformation, which is reversible, and plastic deformation, which is permanent. Key points on the curve include the proportional limit, yield point, ultimate tensile strength, and fracture point, providing essential data for engineering design and failure analysis.

Factors Influencing Stress and Strain Behavior

Material properties such as elasticity, ductility, and hardness significantly influence stress and strain behavior under load conditions. Environmental factors including temperature and loading rate alter the internal microstructure, affecting how materials deform or resist deformation. Geometrical factors like cross-sectional area and shape determine stress distribution and strain localization within the material.

Real-World Applications: Stress and Strain in Engineering

Stress and strain are critical factors in engineering used to analyze material behavior under load, ensuring structural integrity in bridges, buildings, and aircraft. Engineers calculate stress as force per unit area and measure strain as the deformation from the original shape, allowing precise predictions of failure points. Real-world applications include designing materials that withstand high stress levels while maintaining minimal strain to prevent catastrophic failures in infrastructure and machinery.

Summary Table: Stress vs Strain Comparison

Stress quantifies the internal force per unit area within materials, measured in pascals (Pa), indicating how much load a material can withstand before failure. Strain represents the relative deformation or displacement per unit length, a dimensionless measure showing material elongation or compression under stress. The summary table emphasizes stress as an external cause and strain as the resulting effect, distinguishing their roles in material mechanics and structural analysis.

Stress Infographic

libterm.com

libterm.com