Edge joint techniques are essential for joining two boards along their edges to create a wider surface, commonly used in woodworking and carpentry projects. Proper alignment, clamping, and adhesive application ensure a strong, seamless bond that enhances the durability and aesthetic of your completed workpiece. Discover the step-by-step process and expert tips to master edge joints in the rest of this article.

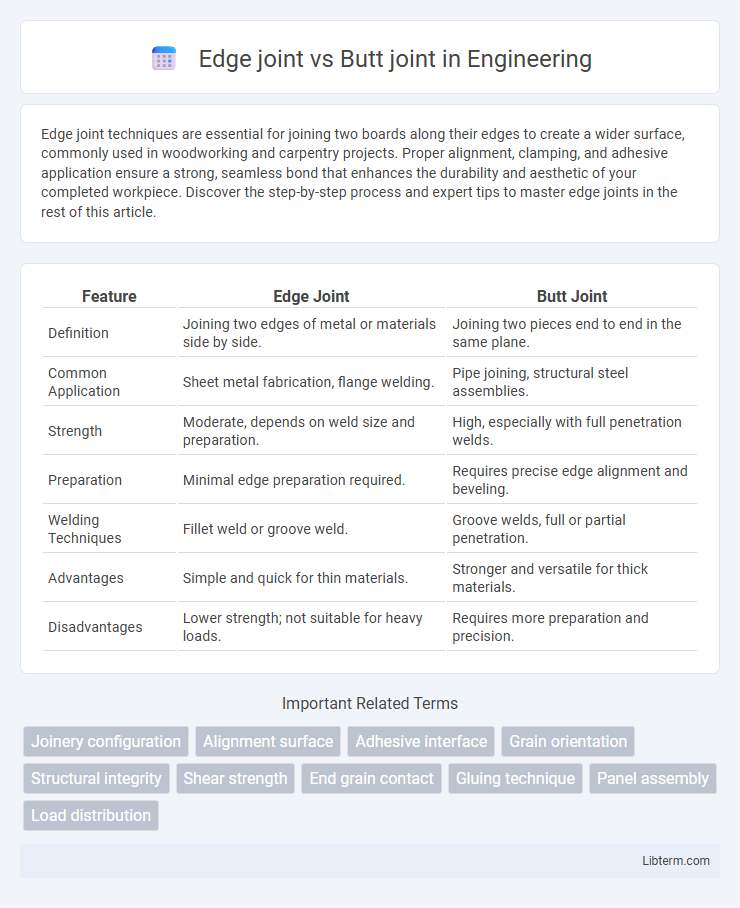

Table of Comparison

| Feature | Edge Joint | Butt Joint |

|---|---|---|

| Definition | Joining two edges of metal or materials side by side. | Joining two pieces end to end in the same plane. |

| Common Application | Sheet metal fabrication, flange welding. | Pipe joining, structural steel assemblies. |

| Strength | Moderate, depends on weld size and preparation. | High, especially with full penetration welds. |

| Preparation | Minimal edge preparation required. | Requires precise edge alignment and beveling. |

| Welding Techniques | Fillet weld or groove weld. | Groove welds, full or partial penetration. |

| Advantages | Simple and quick for thin materials. | Stronger and versatile for thick materials. |

| Disadvantages | Lower strength; not suitable for heavy loads. | Requires more preparation and precision. |

Introduction to Edge Joint and Butt Joint

Edge joint and butt joint are fundamental woodworking and metalworking techniques used to connect two pieces of material. An edge joint involves joining two boards along their edges to create a wider surface, commonly used in panel construction. A butt joint connects two pieces end-to-end or edge-to-face without overlap, often serving as a simple and quick fastening method.

Definition of Edge Joint

An edge joint is a welding or fabrication technique where two metal pieces are aligned side by side, allowing their edges to be joined without overlapping. This joint is commonly used for sheet metals or plates, providing a clean and flush surface ideal for structural or cosmetic purposes. In contrast, a butt joint involves joining two pieces end-to-end, aligning their faces to form a continuous surface.

Definition of Butt Joint

A butt joint is a fundamental woodworking or metalworking joint where two pieces are joined by simply placing their edges together without any special shaping or interlocking. Commonly used in frames, boxes, and basic constructions, butt joints rely heavily on adhesives, fasteners, or welding for strength due to the limited bonding surface. Compared to edge joints, which align long edges to create wider surfaces, butt joints focus on joining end-to-end or side-to-side edges, resulting in quicker assembly but often less structural integrity.

Key Differences Between Edge Joint and Butt Joint

Edge joints involve joining the edges of two boards, typically used to create wider panels by gluing the edges side by side, while butt joints join the end of one board to the face or end of another, forming a simple corner or T-shaped connection. Edge joints require precise alignment and are reinforced with glue, biscuits, or dowels for strength, whereas butt joints rely mainly on mechanical fasteners like nails, screws, or brackets due to their inherently weaker nature. The key difference lies in their structural application and strength: edge joints provide a stronger, flush surface ideal for panel construction, while butt joints are often used for framing and are easier to assemble but less durable without reinforcement.

Strength Comparison: Edge Joint vs Butt Joint

Edge joints provide increased strength by overlapping materials along their edges, creating a larger bonding surface area for adhesives or mechanical fasteners. Butt joints align two pieces end-to-end with minimal contact area, resulting in lower tensile and shear strength compared to edge joints. In applications requiring high load-bearing capacity, edge joints outperform butt joints due to enhanced stress distribution and resistance to separation.

Common Applications of Edge Joints

Edge joints commonly appear in woodworking and metal fabrication where two pieces of the same thickness are joined side by side to create a wider panel or surface, such as tabletops, doors, and panels. This joint type is frequently used in cabinet making and furniture production due to its ability to provide a smooth, continuous surface that can be easily glued or welded. Edge joints also serve in creating structural frames and longer material assemblies, offering enhanced stability and alignment compared to butt joints.

Typical Uses for Butt Joints

Butt joints are commonly used in woodworking, metalworking, and plastic fabrication where two pieces are joined end-to-end or edge-to-edge without overlapping. Typical applications include frame construction, furniture making, and simple box assemblies due to their straightforward alignment and ease of fabrication. While less strong than other joints, butt joints are often reinforced with screws, nails, dowels, or adhesives to enhance durability in everyday construction and repair projects.

Advantages and Disadvantages of Edge Joints

Edge joints provide strong, flush connections ideal for joining sheet metal, plywood, or boards with minimal visible seams, enhancing structural integrity and aesthetic appeal. The key limitations include potential gaps requiring precise alignment and susceptibility to stress concentrations along the joint edge, which may reduce load-bearing capacity under tension or bending. Edge joints are preferred for applications demanding smooth surfaces but may require reinforcement or adhesive bonding for enhanced durability compared to butt joints.

Pros and Cons of Butt Joints

Butt joints are easy to make and require minimal preparation, making them ideal for quick assembly and basic woodworking projects. However, they tend to have lower strength compared to other joints, often necessitating reinforcement with nails, screws, or adhesives to improve durability. Their main disadvantage lies in poor resistance to tension and shear forces, which limits their use in high-stress applications.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on strength requirements and material thickness. Edge joints are ideal for joining two boards side by side, providing a smooth surface for wide panels or tabletops. Butt joints, while simpler to execute, work best for non-structural applications or when reinforced with screws, dowels, or biscuits to enhance stability.

Edge joint Infographic

libterm.com

libterm.com