A scarf joint is a woodworking technique used to join two pieces of wood end-to-end by tapering or beveling their ends for a larger gluing surface, ensuring a strong and seamless connection. This joint is commonly employed in carpentry and boat building to extend the length of materials while maintaining structural integrity. Discover how mastering the scarf joint can enhance Your woodworking projects by reading the rest of this article.

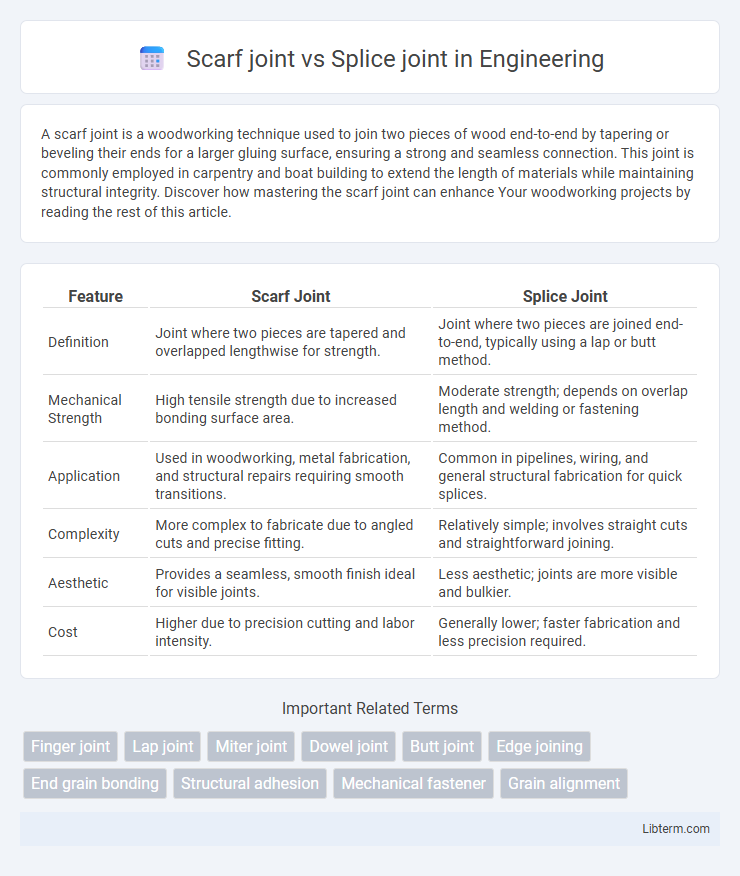

Table of Comparison

| Feature | Scarf Joint | Splice Joint |

|---|---|---|

| Definition | Joint where two pieces are tapered and overlapped lengthwise for strength. | Joint where two pieces are joined end-to-end, typically using a lap or butt method. |

| Mechanical Strength | High tensile strength due to increased bonding surface area. | Moderate strength; depends on overlap length and welding or fastening method. |

| Application | Used in woodworking, metal fabrication, and structural repairs requiring smooth transitions. | Common in pipelines, wiring, and general structural fabrication for quick splices. |

| Complexity | More complex to fabricate due to angled cuts and precise fitting. | Relatively simple; involves straight cuts and straightforward joining. |

| Aesthetic | Provides a seamless, smooth finish ideal for visible joints. | Less aesthetic; joints are more visible and bulkier. |

| Cost | Higher due to precision cutting and labor intensity. | Generally lower; faster fabrication and less precision required. |

Introduction to Scarf Joint and Splice Joint

A scarf joint is a woodworking technique that joins two pieces of wood end-to-end by tapering or beveling their ends to create a longer, seamless surface often used in structural and decorative applications. A splice joint, commonly used in carpentry and metalwork, connects two members by overlapping or inserting their ends together and securing them with adhesives, nails, or bolts for enhanced strength in beams or frameworks. Both joints serve to extend material length but differ in their construction and load distribution characteristics.

Definition and Basic Concepts

A scarf joint is a woodworking or metalworking joint where two pieces are tapered and overlapped to create a longer length, providing increased surface area for gluing or fastening. A splice joint joins two members end-to-end with a straight or stepped cut, often reinforced with plates or dowels to maintain alignment and strength. Both joints are commonly used to extend materials but differ in the shape and method of the cut and the mechanical performance they offer.

Structural Differences Between Scarf and Splice Joints

Scarf joints involve overlapping angled cuts on two wood pieces, creating a longer surface area for adhesive bonding that enhances tensile strength and resists bending forces effectively. Splice joints typically use straight or square cuts and are designed primarily for end-to-end joining, relying heavily on mechanical fasteners or reinforcement to achieve structural stability under shear stress. The scarf joint's angled profile distributes load across a larger gluing surface, improving joint durability compared to the more localized bonding area of splice joints.

Typical Applications and Use Cases

Scarf joints are commonly used in woodworking and timber framing to repair or extend beams by creating a long, strong bond with increased surface area, ideal for curved or angled connections. Splice joints are typically employed in structural engineering and metalwork to join two pieces end-to-end, supporting linear extensions such as in bridge construction or pipeline assembly. Both joints are essential for maintaining structural integrity while allowing for customized lengths and configurations in construction and manufacturing projects.

Advantages of Scarf Joints

Scarf joints offer superior strength and improved load distribution compared to splice joints by increasing the bonded surface area, which enhances structural integrity. These joints provide better resistance to bending and shear forces, making them ideal for applications requiring durability and stability. Additionally, scarf joints allow for a more seamless and aesthetically pleasing connection in woodworking and timber framing.

Advantages of Splice Joints

Splice joints offer superior structural strength and scalability compared to scarf joints, making them ideal for longer wooden components and heavy load applications. Their design allows for easier alignment and more efficient use of materials, resulting in enhanced durability and reduced risk of joint failure. Splice joints also facilitate faster and more accurate assembly in both woodworking and construction projects, improving overall productivity and cost-effectiveness.

Strength and Durability Comparison

Scarf joints provide superior strength and durability compared to splice joints due to their larger glue surface area and interlocking tapered design, which better resists shear and bending forces. Splice joints tend to be weaker under tension and impact stresses because they rely mostly on end-to-end bonding with less surface area for adhesive distribution. In structural applications requiring long-lasting joints under dynamic loads, scarf joints are preferred for their enhanced load transfer capabilities and resistance to joint failure.

Installation Techniques and Tools Required

Scarf joint installation involves precise angled cuts using woodworking tools such as a miter saw, plane, and clamps to ensure tight alignment of the two joining surfaces, often requiring adhesive or fasteners for structural integrity. Splice joint installation typically requires straight cuts with power saws, and tools like biscuits or dowels for alignment, along with clamps and wood glue to secure the joint. Both techniques demand accuracy in cutting and clamping, but scarf joints often require more meticulous shaping and fitting compared to the relatively straightforward splice joint assembly.

Cost and Material Efficiency

Scarf joints offer superior material efficiency by requiring less overlap and reducing waste compared to splice joints, making them ideal for conserving wood or metal. Cost-wise, scarf joints tend to be more labor-intensive due to precise cutting and fitting, potentially increasing labor expenses, while splice joints are simpler and quicker to produce, lowering overall installation costs. Choosing between the two depends on balancing the need for material conservation with labor and fabrication budget constraints.

Choosing the Right Joint for Your Project

Selecting between a scarf joint and a splice joint depends on the structural requirements and aesthetic goals of your woodworking or construction project. Scarf joints provide a tapered overlap ideal for lengthening wood pieces with enhanced strength and smooth transitions, making them suitable for visible, load-bearing applications like beams and trim. Splice joints, featuring straight cuts with flat mating surfaces, offer straightforward alignment and ease of assembly, often preferred in framing or situations prioritizing quick installation over seamless appearance.

Scarf joint Infographic

libterm.com

libterm.com