Elasticity measures how much a product's demand or supply responds to changes in price or other factors, reflecting market sensitivity. Understanding elasticity helps businesses set optimal prices and predict consumer behavior under varying economic conditions. Discover how mastering elasticity can enhance your strategic decisions in the full article ahead.

Table of Comparison

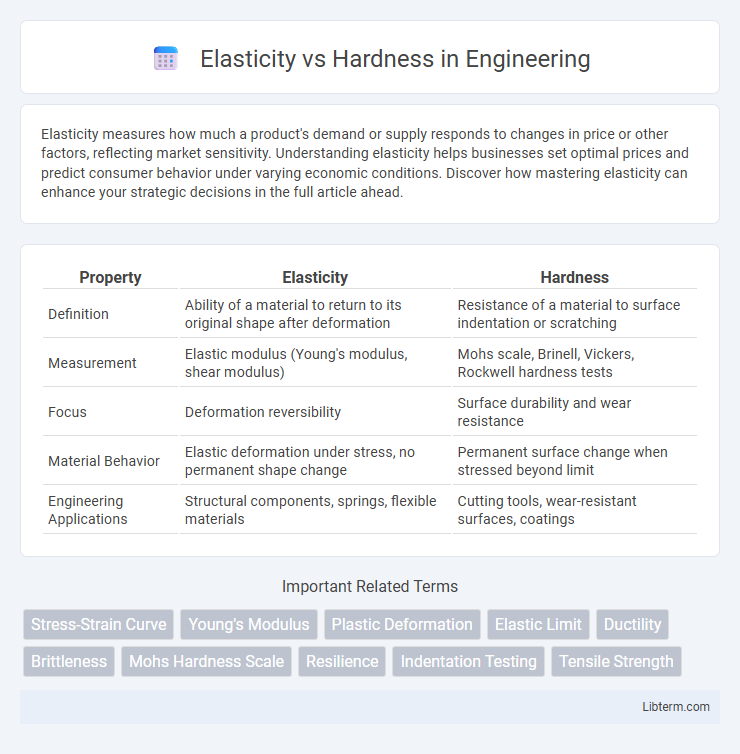

| Property | Elasticity | Hardness |

|---|---|---|

| Definition | Ability of a material to return to its original shape after deformation | Resistance of a material to surface indentation or scratching |

| Measurement | Elastic modulus (Young's modulus, shear modulus) | Mohs scale, Brinell, Vickers, Rockwell hardness tests |

| Focus | Deformation reversibility | Surface durability and wear resistance |

| Material Behavior | Elastic deformation under stress, no permanent shape change | Permanent surface change when stressed beyond limit |

| Engineering Applications | Structural components, springs, flexible materials | Cutting tools, wear-resistant surfaces, coatings |

Introduction to Elasticity and Hardness

Elasticity measures a material's ability to return to its original shape after deformation, quantified by the modulus of elasticity or Young's modulus. Hardness indicates a material's resistance to permanent surface indentation or scratching, commonly assessed by tests such as Mohs hardness, Rockwell, or Vickers hardness. Understanding both properties is critical for selecting materials in engineering applications based on flexibility or durability requirements.

Defining Elasticity

Elasticity refers to a material's ability to return to its original shape and size after the removal of applied stress, characterized by the elastic modulus or Young's modulus. It quantifies how much a material can deform elastically without permanent deformation, crucial in engineering and physics for designing resilient structures. Hardness measures resistance to permanent surface indentation or abrasion, indicating a material's durability rather than its ability to deform and recover.

Understanding Hardness

Hardness measures a material's resistance to permanent shape change or deformation under applied force, often quantified using scales like Mohs, Vickers, or Rockwell. Unlike elasticity, which describes a material's ability to return to its original shape after stress removal, hardness directly relates to surface durability and wear resistance. Understanding hardness is essential in selecting materials for applications requiring abrasion resistance, indentation resistance, and structural integrity.

Key Differences Between Elasticity and Hardness

Elasticity measures a material's ability to return to its original shape after deformation, quantifying reversible strain under applied stress. Hardness indicates a material's resistance to permanent surface deformation or indentation, reflecting its strength and wear resistance. While elasticity is related to flexibility and recovery, hardness focuses on durability and resistance to external mechanical forces.

Measurement Methods for Elasticity

Measurement methods for elasticity primarily involve techniques such as tensile testing, dynamic mechanical analysis (DMA), and ultrasonic pulse velocity testing, which assess a material's ability to deform and return to its original shape under stress. Tensile testing measures the stress-strain relationship, providing precise data on Young's modulus, a fundamental indicator of elasticity. Dynamic mechanical analysis and ultrasonic methods offer insights into viscoelastic properties and stiffness by evaluating material responses to oscillatory forces or sound waves, respectively.

Hardness Testing Techniques

Hardness testing techniques measure a material's resistance to deformation, abrasion, or indentation, providing critical data for evaluating wear resistance and durability. Common methods include Brinell, Rockwell, Vickers, and Mohs hardness tests, each applying different scales and types of forces, such as indentation load or scratch resistance. These standardized procedures enable precise characterization of materials in manufacturing, quality control, and material science applications.

Applications of Elastic Materials

Elastic materials are widely used in industries requiring vibration damping, flexible connectors, and impact absorption due to their ability to return to original shape after deformation. Applications include automotive suspension systems, medical devices like prosthetics, and consumer products such as elastic textiles and wearable technology. Their energy-storing capacity makes them essential in mechanical springs, seals, and flexible electronics.

Uses of Hard Materials

Hard materials are essential in manufacturing cutting tools, abrasives, and wear-resistant surfaces due to their high resistance to deformation and scratching. They are widely used in construction for structural components such as steel beams and concrete reinforcements to ensure durability and safety. Industrial applications leverage the hardness of ceramics and carbides to extend the lifespan of machine parts exposed to extreme pressure and friction.

Factors Influencing Elasticity and Hardness

Elasticity and hardness are influenced by atomic structure and bonding forces; materials with strong ionic or covalent bonds exhibit high hardness, while those with flexible metallic or van der Waals bonds display greater elasticity. Temperature significantly affects elasticity, as increased thermal energy can reduce intermolecular forces, leading to decreased elasticity and altered hardness. Microstructural factors such as grain size, dislocations, and phase composition also determine the balance between elasticity and hardness in metals and polymers.

Conclusion: Choosing Between Elasticity and Hardness

Selecting between elasticity and hardness depends on the specific application requirements; elasticity is ideal for materials needing flexibility and the ability to return to original shape after deformation, while hardness suits environments demanding resistance to surface wear and indentation. For components subjected to dynamic loads or frequent deformation, materials with high elasticity ensure durability and performance. Conversely, hardness is critical in tools and protective coatings where surface durability is paramount.

Elasticity Infographic

libterm.com

libterm.com