Adaptive control is a dynamic approach that adjusts system parameters in real-time to maintain optimal performance despite changing conditions or uncertainties. This method enhances system stability and responsiveness by continuously learning and adapting to new environments. Explore the rest of the article to understand how adaptive control can improve your system's efficiency and reliability.

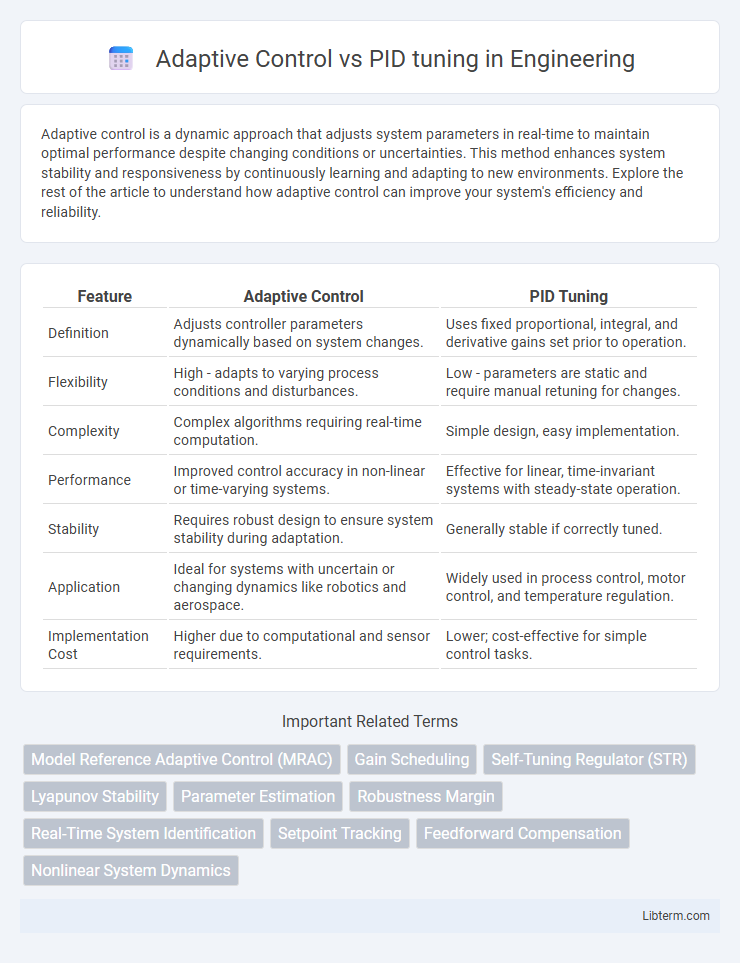

Table of Comparison

| Feature | Adaptive Control | PID Tuning |

|---|---|---|

| Definition | Adjusts controller parameters dynamically based on system changes. | Uses fixed proportional, integral, and derivative gains set prior to operation. |

| Flexibility | High - adapts to varying process conditions and disturbances. | Low - parameters are static and require manual retuning for changes. |

| Complexity | Complex algorithms requiring real-time computation. | Simple design, easy implementation. |

| Performance | Improved control accuracy in non-linear or time-varying systems. | Effective for linear, time-invariant systems with steady-state operation. |

| Stability | Requires robust design to ensure system stability during adaptation. | Generally stable if correctly tuned. |

| Application | Ideal for systems with uncertain or changing dynamics like robotics and aerospace. | Widely used in process control, motor control, and temperature regulation. |

| Implementation Cost | Higher due to computational and sensor requirements. | Lower; cost-effective for simple control tasks. |

Introduction to Adaptive Control and PID Tuning

Adaptive control dynamically adjusts controller parameters in real-time to handle changing system conditions and uncertainties, enhancing performance in complex or nonlinear environments. PID tuning involves setting proportional, integral, and derivative gains based on system response characteristics to stabilize and optimize control loops for steady-state accuracy and transient behavior. Comparing adaptive control with PID tuning highlights how adaptive strategies provide robustness against system variations where fixed-parameter PID controllers may struggle.

Fundamentals of PID Control Systems

PID control systems rely on proportional, integral, and derivative terms to regulate process variables by minimizing error and providing stability. Adaptive control dynamically adjusts PID parameters in real-time to accommodate system changes and non-linearities, enhancing performance where fixed PID tuning may fail. Understanding the fundamentals of PID control is essential for implementing adaptive algorithms that optimize system response under varying operating conditions.

What is Adaptive Control?

Adaptive Control is a dynamic control strategy that continuously adjusts controller parameters in real-time to maintain optimal system performance amid varying process conditions and uncertainties. Unlike traditional PID tuning, which relies on fixed parameters set during initial calibration, Adaptive Control uses algorithms such as model reference adaptive systems (MRAS) or self-tuning regulators to respond to changes in system behavior automatically. This approach enhances system stability and responsiveness in applications with nonlinearities or time-varying dynamics.

Key Differences Between Adaptive and PID Control

Adaptive control dynamically adjusts controller parameters in real-time to accommodate system changes and uncertainties, whereas PID tuning relies on fixed parameter settings optimized for steady-state performance. Adaptive control excels in handling nonlinearities and varying operating conditions without manual retuning, while PID controllers may require frequent manual adjustments to maintain optimal performance. The key difference lies in adaptive control's feedback mechanism that continuously modifies control laws, contrasting with the static gain nature of traditional PID tuning.

Advantages of PID Tuning

PID tuning offers straightforward implementation and reliable control for a wide range of industrial processes, making it a preferred choice for systems with stable dynamics. It provides predictable performance and ease of maintenance, reducing downtime and operational costs. The well-established tuning methods and extensive industry experience ensure effective control without the complexity of adaptive algorithms.

Benefits of Adaptive Control

Adaptive control offers significant advantages over traditional PID tuning by continuously adjusting controller parameters in real time to accommodate changes in system dynamics and external disturbances. This ability enhances system performance, stability, and robustness in uncertain or time-varying environments, reducing the need for manual retuning. The increased flexibility of adaptive control leads to improved precision and efficiency in complex industrial applications such as robotics, aerospace, and chemical process control.

Use Cases: When to Prefer PID or Adaptive Control

PID tuning is ideal for systems with stable, predictable dynamics and well-defined setpoints, such as temperature control in HVAC systems or motor speed regulation, where simplicity and reliability are paramount. Adaptive control excels in environments with significant variability or uncertainty, like aerospace flight control or chemical reactors with fluctuating parameters, where real-time adjustment improves performance and robustness. Choosing between PID and adaptive control depends on the system's complexity, variability, and the need for continuous parameter adjustment to maintain optimal operation.

Implementation Challenges and Solutions

Adaptive control systems face implementation challenges such as model uncertainties, time-varying parameters, and real-time computational demands, which complicate controller design and stability assurance. PID tuning struggles with non-linearities and changing process dynamics, often requiring manual retuning and heuristic approaches that lack robustness under variable conditions. Solutions to these challenges include employing self-tuning algorithms, robust adaptive laws, and combining adaptive techniques with observer-based estimation to enhance performance and reliability in complex control environments.

Performance Comparison in Real-World Applications

Adaptive control systems dynamically adjust parameters in real time to maintain optimal performance under varying conditions, outperforming traditional PID tuning in complex, nonlinear, or time-varying processes. PID controllers require manual retuning or gain scheduling for changes in system dynamics, often leading to slower response and reduced accuracy in real-world applications such as robotics, aerospace, and industrial automation. Studies show adaptive control improves stability, reduces overshoot, and enhances disturbance rejection, making it more effective for processes with significant uncertainty or changing operating environments.

Future Trends in Control System Technologies

Adaptive control is increasingly integrated with machine learning algorithms to enhance real-time system response and robustness, surpassing traditional PID tuning limitations. Future trends emphasize leveraging AI-driven adaptive controllers for complex, nonlinear, and time-varying systems, enabling improved self-optimization and fault tolerance. Advances in sensor technology and IoT connectivity further facilitate data-rich environments, allowing continuous refinement of control parameters beyond static PID tuning methods.

Adaptive Control Infographic

libterm.com

libterm.com