Chip curling occurs when the edges of a chip lift and curl during the soldering process, leading to poor electrical connections and potential device failure. Factors such as uneven heating, rapid temperature changes, and improper solder paste application contribute to this defect. Discover effective methods to prevent chip curling and ensure the reliability of your electronic assemblies in the rest of this article.

Table of Comparison

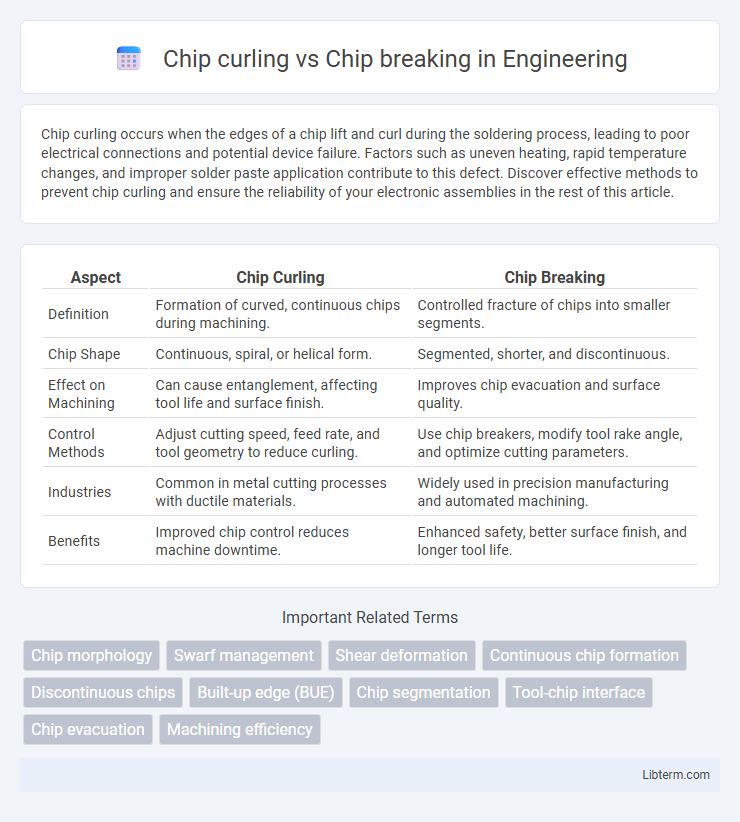

| Aspect | Chip Curling | Chip Breaking |

|---|---|---|

| Definition | Formation of curved, continuous chips during machining. | Controlled fracture of chips into smaller segments. |

| Chip Shape | Continuous, spiral, or helical form. | Segmented, shorter, and discontinuous. |

| Effect on Machining | Can cause entanglement, affecting tool life and surface finish. | Improves chip evacuation and surface quality. |

| Control Methods | Adjust cutting speed, feed rate, and tool geometry to reduce curling. | Use chip breakers, modify tool rake angle, and optimize cutting parameters. |

| Industries | Common in metal cutting processes with ductile materials. | Widely used in precision manufacturing and automated machining. |

| Benefits | Improved chip control reduces machine downtime. | Enhanced safety, better surface finish, and longer tool life. |

Introduction to Chip Curling and Chip Breaking

Chip curling and chip breaking are critical phenomena in metal cutting that influence surface finish and tool life. Chip curling occurs when the cutting edge causes the material to deform plastically, forming a curled chip that helps dissipate heat and reduce cutting forces. In contrast, chip breaking involves intentionally fracturing the chip into smaller segments to prevent entanglement and improve machining efficiency.

Importance of Chip Control in Machining

Effective chip control in machining directly impacts surface finish quality, tool life, and operational safety by preventing chip entanglement and machine damage. Chip curling facilitates manageable chip shapes that eject smoothly, reducing heat buildup and ensuring consistent cutting conditions. Conversely, chip breaking is essential for producing small, segmented chips that minimize tool wear and improve chip evacuation in high-speed machining environments.

How Chip Curling Occurs in Cutting Operations

Chip curling occurs during cutting operations when the shear force causes the metal to plastically deform and bend away from the cutting tool, forming a curved chip shape. This deformation is influenced by cutting speed, tool geometry, and material properties, which determine the chip's stress distribution and thermal conditions. The extent of chip curling directly affects surface finish, tool wear, and machining efficiency in metal cutting processes.

Mechanisms Behind Chip Breaking

Chip breaking occurs when controlled cracks form in the chip during machining, preventing long, continuous chips that can entangle tools and workpieces. The mechanisms behind chip breaking involve inducing stress concentrations through tool geometry, cutting speed, and feed rate adjustments, which create fractures at predefined intervals. In contrast, chip curling focuses on bending the chip to reduce chip-tool contact length, but does not inherently cause chip fragmentation like chip breaking does.

Factors Influencing Chip Curling

Factors influencing chip curling include cutting speed, feed rate, tool geometry, and material properties. Higher cutting speeds and larger feed rates tend to increase chip curling due to greater strain energy and thermal effects. Tool rake angle and workpiece ductility also significantly affect chip deformation behavior during machining.

Tools and Inserts for Optimal Chip Breaking

Tool geometry and insert design critically influence chip curling and chip breaking efficiency in machining processes. Inserts with sharp edges, chip breakers, and optimized rake angles promote controlled chip fragmentation, reducing heat buildup and tool wear. Selecting tools with advanced coatings and precision-ground chip breakers enhances chip control, improving surface finish and operational productivity.

Impacts on Surface Finish and Tool Life

Chip curling improves surface finish by promoting smooth chip evacuation, reducing built-up edge formation that can mar the workpiece. In contrast, chip breaking creates smaller, segmented chips that prevent tool clogging but may increase micro-chatter, potentially compromising surface quality. Tool life benefits from chip curling due to consistent heat dissipation and reduced cutting forces, whereas aggressive chip breaking can accelerate tool wear by introducing abrupt mechanical stresses.

Safety Concerns: Managing Chip Shape

Managing chip shape is critical for ensuring safety in machining processes, as different chip types pose various hazards. Curling chips typically form continuous spirals that can entangle around machinery or operators, increasing the risk of injury or equipment damage. In contrast, breaking chips produce short, segmented pieces that are easier to control and dispose of, reducing the potential for sharp edges or airborne debris that could cause harm.

Applications Favoring Chip Curling vs Chip Breaking

Applications favoring chip curling typically involve materials like aluminum and mild steel where controlled chip formation improves surface finish and tool life by producing manageable, curled chips that reduce heat generation. Chip breaking is preferred in machining brittle or hard materials such as cast iron and hardened steels, where breaking chips into smaller fragments prevents chip entanglement and enhances machining safety. Selecting chip curling or breaking depends heavily on factors like material properties, cutting conditions, and desired machinability to optimize productivity and tool performance.

Future Developments in Chip Control Technology

Future developments in chip control technology will emphasize enhanced precision in differentiating chip curling from chip breaking to improve machining efficiency and tool life. Advanced sensors and AI-driven monitoring systems are expected to enable real-time adaptive controls that optimize cutting parameters based on chip formation patterns. Integration of machine learning algorithms with high-speed cameras will facilitate predictive maintenance and minimize issues related to chip disposal in automated manufacturing environments.

Chip curling Infographic

libterm.com

libterm.com