Ultrasonic peening enhances material strength and fatigue resistance by inducing deep compressive residual stresses using high-frequency ultrasonic vibrations. This process refines the microstructure, reducing surface defects and improving the durability of metals. Explore the full article to learn how ultrasonic peening can extend the life and performance of your components.

Table of Comparison

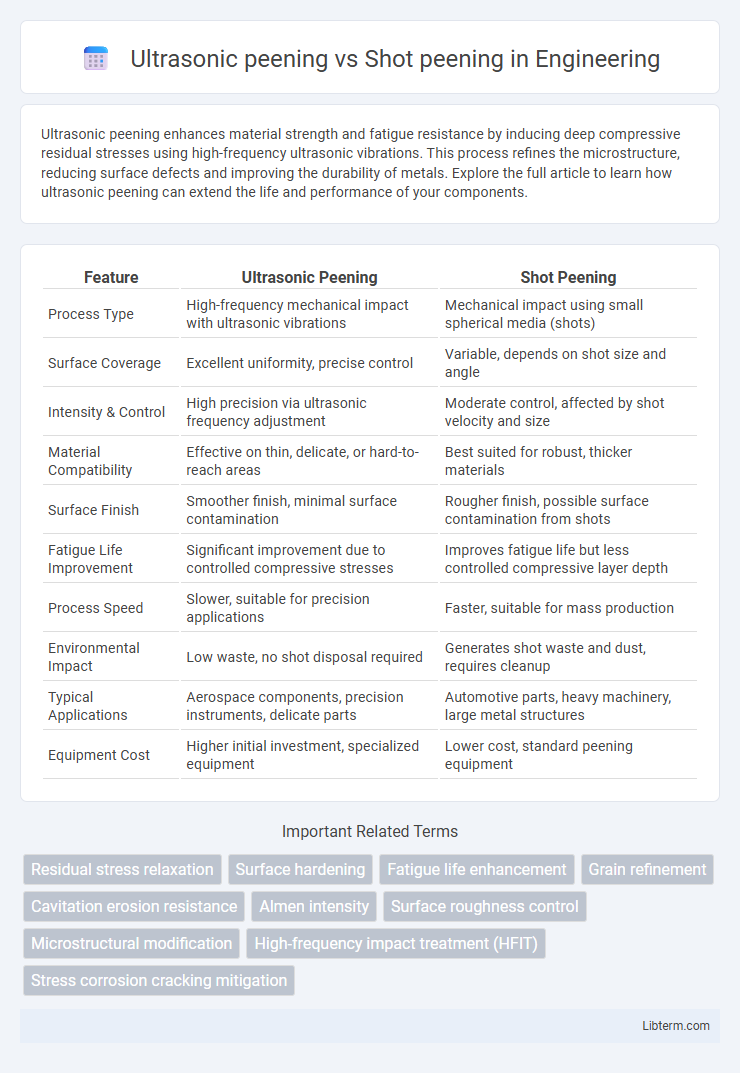

| Feature | Ultrasonic Peening | Shot Peening |

|---|---|---|

| Process Type | High-frequency mechanical impact with ultrasonic vibrations | Mechanical impact using small spherical media (shots) |

| Surface Coverage | Excellent uniformity, precise control | Variable, depends on shot size and angle |

| Intensity & Control | High precision via ultrasonic frequency adjustment | Moderate control, affected by shot velocity and size |

| Material Compatibility | Effective on thin, delicate, or hard-to-reach areas | Best suited for robust, thicker materials |

| Surface Finish | Smoother finish, minimal surface contamination | Rougher finish, possible surface contamination from shots |

| Fatigue Life Improvement | Significant improvement due to controlled compressive stresses | Improves fatigue life but less controlled compressive layer depth |

| Process Speed | Slower, suitable for precision applications | Faster, suitable for mass production |

| Environmental Impact | Low waste, no shot disposal required | Generates shot waste and dust, requires cleanup |

| Typical Applications | Aerospace components, precision instruments, delicate parts | Automotive parts, heavy machinery, large metal structures |

| Equipment Cost | Higher initial investment, specialized equipment | Lower cost, standard peening equipment |

Introduction to Surface Enhancement Techniques

Ultrasonic peening uses high-frequency ultrasonic waves to induce compressive residual stresses on metal surfaces, enhancing fatigue strength and resistance to stress corrosion cracking. Shot peening involves bombarding the surface with small spherical media to create plastic deformation and improve surface hardness and durability. Both techniques serve as critical surface enhancement methods in industries such as aerospace and automotive, with ultrasonic peening offering more precise control and reduced surface roughness compared to traditional shot peening.

What is Ultrasonic Peening?

Ultrasonic peening is a surface enhancement technique that uses high-frequency ultrasonic vibrations combined with small spherical media to induce compressive residual stresses on metal surfaces, improving fatigue strength and resistance to stress corrosion cracking. Unlike shot peening, which relies on traditional mechanical impact, ultrasonic peening operates at ultrasonic frequencies, allowing precise control and deeper stress layer penetration. This process is commonly applied in aerospace, automotive, and power generation industries for enhancing critical components.

What is Shot Peening?

Shot peening is a metal surface treatment process that involves bombarding the material with small spherical media called shots to induce compressive residual stresses and improve fatigue strength. This technique enhances resistance to stress corrosion cracking and surface wear by creating a uniform layer of micro-deformations on the metal. Compared to ultrasonic peening, shot peening uses mechanical impact from high-velocity shots rather than ultrasonic vibrations for surface enhancement.

Mechanisms of Action: Ultrasonic vs Shot Peening

Ultrasonic peening employs high-frequency mechanical vibrations transmitted via a sonotrode to induce plastic deformation and compressive residual stresses on metal surfaces, enhancing fatigue resistance and reducing crack initiation. Shot peening utilizes high-velocity impact of small spherical media, creating numerous dimples that plastically deform the surface and generate compressive stresses to improve surface hardness and durability. Both methods differ fundamentally in energy delivery: ultrasonic peening relies on vibrational energy for precise, localized treatment, while shot peening uses kinetic energy for widespread surface coverage.

Key Applications in Industry

Ultrasonic peening is widely used in aerospace and automotive industries for enhancing fatigue resistance and reducing residual stress in critical engine components and structural parts. Shot peening dominates in heavy industries such as shipbuilding, construction, and manufacturing, where it improves durability and prevents stress corrosion cracking in large-scale metal parts like gears, springs, and turbines. Both methods extend service life, but ultrasonic peening is preferred for precision applications requiring minimal surface damage, while shot peening suits broader applications needing robust surface strengthening.

Comparative Analysis of Process Efficiency

Ultrasonic peening utilizes high-frequency ultrasonic waves to induce surface compressive stresses, providing faster coverage with lower energy consumption compared to shot peening, which relies on high-velocity metallic shots impacting the surface. The precision of ultrasonic peening results in reduced material waste and minimal surface damage, enhancing overall process efficiency. Shot peening, while effective for large-scale applications, often requires longer processing times and more maintenance due to shot contamination and equipment wear.

Surface Finish and Residual Stress Comparison

Ultrasonic peening provides a finer and more uniform surface finish compared to shot peening due to its high-frequency mechanical vibrations that produce controlled impacts on the material surface. Residual stress profiles generated by ultrasonic peening tend to be deeper and more compressive, enhancing fatigue resistance more effectively than the typically shallower and less uniform residual stresses from shot peening. The precise energy input in ultrasonic peening enables superior control over stress distribution and surface morphology, crucial for high-performance metal components.

Advantages and Disadvantages of Each Method

Ultrasonic peening offers precise control, deeper compressive residual stresses, and minimal surface contamination, making it ideal for high-strength alloys and delicate geometries; however, it requires specialized equipment and higher operational costs. Shot peening provides widespread applicability, cost-effectiveness, and ease of use for large or complex components but may lead to surface roughness and inconsistent coverage if not properly controlled. Each method's advantages and disadvantages depend on specific material properties, component design, and the required fatigue performance improvements.

Cost and Operational Considerations

Ultrasonic peening typically incurs higher initial equipment costs compared to shot peening due to its advanced technology and precision components. Operationally, ultrasonic peening offers lower maintenance and reduces consumable use, leading to decreased long-term expenses. Shot peening requires ongoing media replacement and cleaning processes, increasing labor and material costs over time.

Choosing the Right Peening Technique for Your Needs

Ultrasonic peening offers precise control over intensity and coverage, making it ideal for delicate or complex components requiring minimal surface distortion, while shot peening provides a more aggressive treatment suitable for larger, robust parts needing enhanced fatigue strength. Selecting the right peening technique depends on factors such as material type, desired residual stress profile, component geometry, and surface finish requirements. Understanding these parameters ensures optimized performance and longevity in applications ranging from aerospace and automotive to medical devices.

Ultrasonic peening Infographic

libterm.com

libterm.com