K truss design maximizes structural stability by efficiently distributing loads through its triangular framework, making it ideal for bridges, roofs, and large-span structures. Its unique K-shaped configuration reduces material usage while maintaining high strength, enhancing both durability and cost-effectiveness. Explore the rest of the article to understand how a K truss can optimize Your engineering projects with innovative design principles.

Table of Comparison

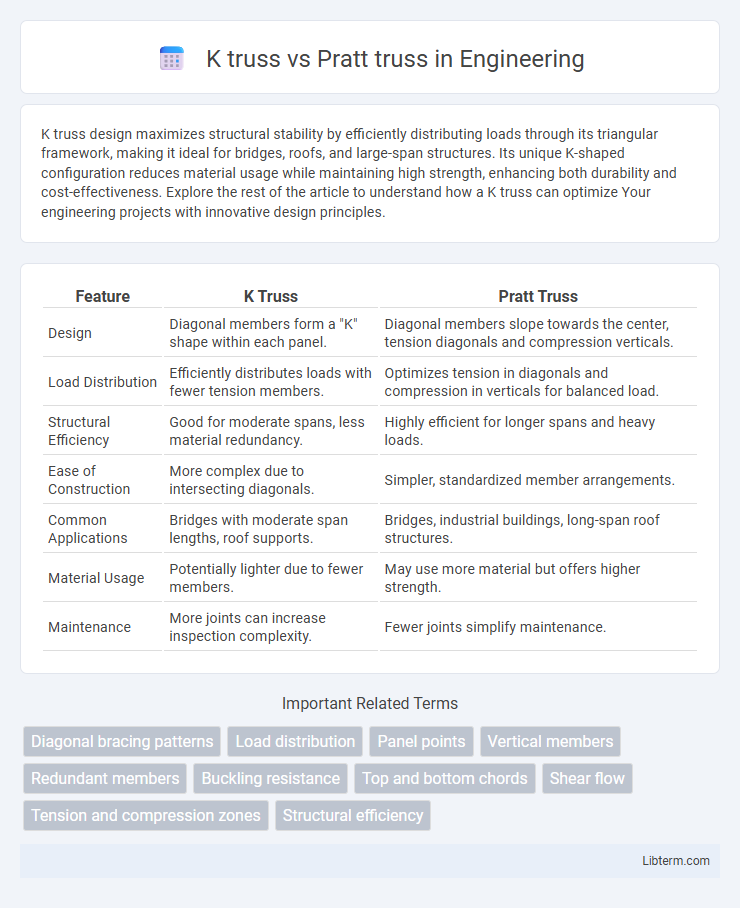

| Feature | K Truss | Pratt Truss |

|---|---|---|

| Design | Diagonal members form a "K" shape within each panel. | Diagonal members slope towards the center, tension diagonals and compression verticals. |

| Load Distribution | Efficiently distributes loads with fewer tension members. | Optimizes tension in diagonals and compression in verticals for balanced load. |

| Structural Efficiency | Good for moderate spans, less material redundancy. | Highly efficient for longer spans and heavy loads. |

| Ease of Construction | More complex due to intersecting diagonals. | Simpler, standardized member arrangements. |

| Common Applications | Bridges with moderate span lengths, roof supports. | Bridges, industrial buildings, long-span roof structures. |

| Material Usage | Potentially lighter due to fewer members. | May use more material but offers higher strength. |

| Maintenance | More joints can increase inspection complexity. | Fewer joints simplify maintenance. |

Introduction to K Truss and Pratt Truss

K Truss features a unique diagonal configuration forming a "K" shape, optimizing load distribution and reducing beam length for efficient material use in bridges and roof systems. Pratt Truss, distinguished by its vertical members and diagonals slanting toward the center, excels in handling compressive forces on verticals and tensile forces on diagonals, providing structural stability in bridges. Both trusses leverage geometric design principles to maximize strength and minimize material usage in architectural and engineering applications.

Historical Background of Truss Designs

K truss and Pratt truss designs emerged during the 19th century as engineers sought efficient structural solutions for bridges. The Pratt truss, patented in 1844 by Thomas and Caleb Pratt, became widely popular due to its effective use of diagonal members under tension and verticals under compression, optimizing material use for railroad bridges. The K truss, developed later in the early 20th century, introduced a more complex web arrangement forming "K" shapes between vertical members, aiming to enhance load distribution and rigidity in long-span bridges.

Structural Overview: K Truss

The K truss features a distinctive web of diagonal members forming a "K" shape between the top and bottom chords, enhancing load distribution and reducing member lengths, which improves structural efficiency under compressive forces. Its design allows for better handling of both bending moments and shear forces compared to traditional trusses, making it suitable for bridges and long-span roof structures. The unique geometry minimizes deflection and optimizes material usage, contributing to increased stability and durability in various construction applications.

Structural Overview: Pratt Truss

The Pratt truss features diagonal members that slope towards the center of the span under tension, while vertical members handle compression, optimizing material efficiency for longer spans. Its design distributes loads effectively, making it a popular choice for bridges and roof supports where dynamic loads are common. Compared to the K truss, the Pratt truss offers simpler geometry and easier construction, enhancing its structural efficiency in various engineering applications.

Material Efficiency Comparison

K truss designs exhibit higher material efficiency compared to Pratt trusses due to their shorter diagonal members which reduce bending moments and allow the use of lighter materials. Pratt trusses typically require stronger, heavier diagonal elements to resist tension, increasing overall material consumption. Studies indicate K trusses can achieve up to 15-20% material savings in steel usage while maintaining comparable load-bearing capacities in bridge and roof structures.

Load Distribution and Performance

K truss design offers superior load distribution by dividing loads more evenly through its diagonal and vertical members, reducing stress concentrations and improving structural efficiency. Pratt truss, characterized by diagonal members slanting towards the center under tension, excels in handling dynamic and variable loads, optimizing performance in bridges and frameworks subjected to fluctuating forces. The K truss typically provides enhanced rigidity and stability for heavy loads, while the Pratt truss delivers greater adaptability for longer spans and lighter materials.

Applications in Modern Construction

K truss and Pratt truss designs offer distinct advantages in modern construction applications, with K trusses commonly used for long-span bridges and roof structures due to their efficient load distribution and reduced material usage. Pratt trusses are favored in building frameworks and shorter span bridges for their simplicity, ease of fabrication, and effective tension-compression member arrangement. Both truss types contribute to optimizing structural stability and cost-effectiveness in contemporary engineering projects.

Advantages of K Truss

The K Truss design offers superior distribution of loads by dividing compression and tension forces more efficiently, reducing the length of compression members and minimizing buckling risks. Its configuration provides enhanced stability and rigidity, especially useful in longer span bridges, leading to improved structural performance under heavy loads. The design also optimizes material use, resulting in lower weight without compromising strength, making it both cost-effective and durable compared to the Pratt Truss.

Advantages of Pratt Truss

The Pratt truss offers superior efficiency in handling both tension and compression forces, making it ideal for longer spans with heavy loads. Its diagonal members primarily experience tension, which reduces material fatigue and enhances durability compared to the K truss design. This optimized force distribution results in easier construction, lower material costs, and increased structural stability for bridges and roof systems.

Selection Criteria: Which Truss to Choose?

K truss offers better load distribution and reduced bending moments, making it ideal for longer spans and heavier loads. Pratt truss provides economical construction with simpler diagonal members under tension, suitable for shorter spans and lighter loads. Selection depends on span length, load requirements, and cost efficiency, where K truss excels in structural performance and Pratt truss favors material savings.

K truss Infographic

libterm.com

libterm.com