A check valve is a crucial component designed to allow fluid to flow in one direction while preventing backflow, thereby protecting your system from potential damage. It operates automatically, opening with forward flow and closing tightly when flow reverses, ensuring efficient operation and safety. Explore the rest of the article to discover the types, applications, and maintenance tips for check valves.

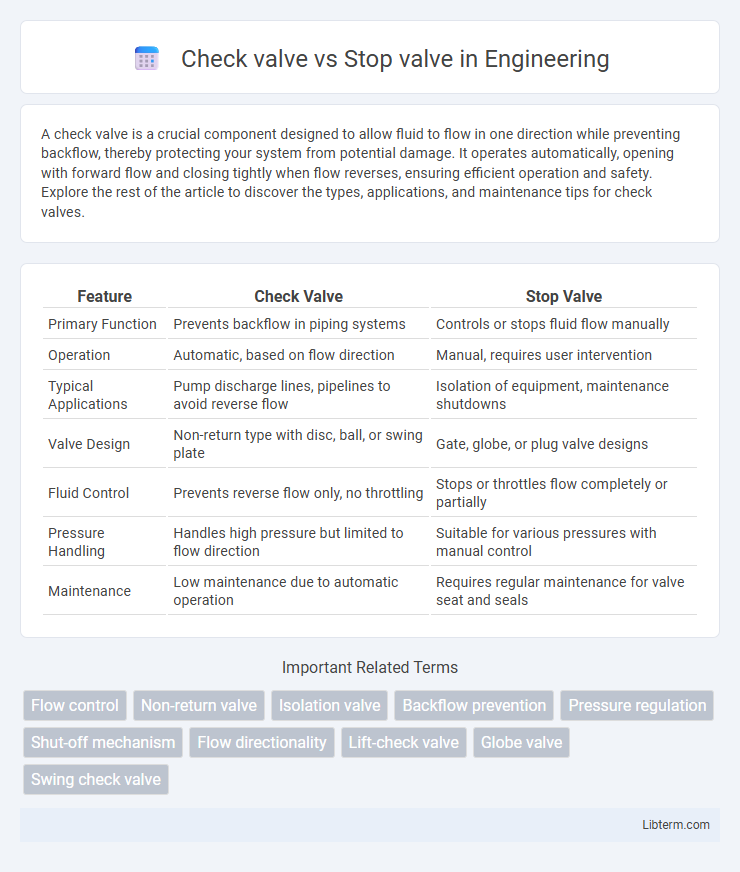

Table of Comparison

| Feature | Check Valve | Stop Valve |

|---|---|---|

| Primary Function | Prevents backflow in piping systems | Controls or stops fluid flow manually |

| Operation | Automatic, based on flow direction | Manual, requires user intervention |

| Typical Applications | Pump discharge lines, pipelines to avoid reverse flow | Isolation of equipment, maintenance shutdowns |

| Valve Design | Non-return type with disc, ball, or swing plate | Gate, globe, or plug valve designs |

| Fluid Control | Prevents reverse flow only, no throttling | Stops or throttles flow completely or partially |

| Pressure Handling | Handles high pressure but limited to flow direction | Suitable for various pressures with manual control |

| Maintenance | Low maintenance due to automatic operation | Requires regular maintenance for valve seat and seals |

Introduction to Check Valves and Stop Valves

Check valves are mechanical devices designed to allow fluid flow in one direction, preventing backflow and protecting pumps and compressors in pipelines. Stop valves, also known as shut-off valves, are used to completely stop or regulate the flow of fluid in a pipeline, providing precise control over system operation. Both valves are essential in fluid control systems but serve distinct functions based on flow direction and control requirements.

Fundamental Differences Between Check and Stop Valves

Check valves allow fluid to flow in one direction only, preventing backflow and protecting equipment from damage. Stop valves, on the other hand, control the flow by opening or closing completely or partially to regulate or shut off fluid movement. The fundamental difference lies in functionality: check valves provide automatic flow control based on pressure differences, whereas stop valves require manual or mechanical operation for flow management.

How Check Valves Work: Principle and Applications

Check valves operate on the principle of allowing fluid to flow in one direction while preventing backflow, using a mechanical disc or ball that closes when reverse flow occurs. These valves are commonly applied in water and wastewater systems, pumps, and compressors to protect equipment and maintain unidirectional flow. Their automatic operation without manual intervention makes them essential in ensuring system safety and efficiency in various industrial and domestic applications.

Stop Valves Explained: Operation and Uses

Stop valves control fluid flow by completely stopping or allowing passage, operated through a rotating or linear movement of a valve stem that presses a disc or plug against a seat. Commonly used in plumbing and industrial systems, stop valves provide precise shut-off capabilities for maintenance or emergency situations, ensuring system isolation without pressure drops. Their robust design supports diverse applications, including water supply lines, gas systems, and HVAC setups, facilitating reliable operation under varying pressure and temperature conditions.

Key Advantages of Check Valves

Check valves prevent backflow by allowing fluid to flow in only one direction, reducing the risk of contamination and equipment damage. They operate automatically without requiring manual intervention or external power, ensuring reliable protection and minimal maintenance. Their key advantages include safeguarding pumps and compressors, maintaining system pressure, and enhancing overall operational safety in fluid handling systems.

Main Benefits of Stop Valves

Stop valves offer precise flow control and quick shutoff capabilities, making them ideal for applications requiring reliable isolation of fluid lines. Their robust design ensures minimal leakage and enhanced durability under high pressure and temperature conditions. Compared to check valves, stop valves provide manual operation flexibility, allowing users to start, stop, or regulate flow as needed for maintenance or safety purposes.

Common Applications: Where to Use Each Valve

Check valves are primarily used in piping systems to prevent backflow and protect pumps and compressors in water treatment, chemical processing, and HVAC systems. Stop valves, designed for flow control and shutdown, are commonly found in residential plumbing, gas lines, and industrial equipment where manual flow interruption is required. Selecting between check and stop valves depends on the need for automatic flow prevention versus manual flow isolation in applications.

Installation and Maintenance Considerations

Check valves require installation in the correct flow direction to prevent backflow, ensuring system protection without manual operation. Maintenance involves periodic inspection for debris buildup and valve wear, often requiring less frequent service due to their automatic function. Stop valves, installed to control flow manually, demand regular operation and sealing checks to prevent leaks and ensure reliable shutoff during maintenance or emergencies.

Cost Comparison: Check Valve vs Stop Valve

Check valves generally cost less upfront due to their simpler design and automatic operation, requiring minimal maintenance and no external power or manual control. Stop valves tend to have higher initial costs because of their manual control mechanism and more complex construction, but they offer precise flow regulation and complete shutoff capabilities. Over time, maintenance expenses for stop valves can increase, whereas check valves often provide cost savings in long-term operational efficiency and lower labor requirements.

Choosing the Right Valve: Factors to Consider

Choosing the right valve depends on the specific function required in the piping system; check valves are ideal for preventing backflow by automatically allowing fluid flow in one direction, while stop valves offer manual control to start or stop flow entirely. Key factors to consider include the need for flow control versus flow prevention, pressure ratings, and maintenance requirements. Material compatibility with the fluid and system operational conditions also plays a critical role in selecting either valve type.

Check valve Infographic

libterm.com

libterm.com