Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. The process involves heating the material to a specific temperature, maintaining that temperature, and then cooling it slowly to remove internal stresses and improve its structural uniformity. Explore the rest of the article to understand how annealing can optimize your materials and applications.

Table of Comparison

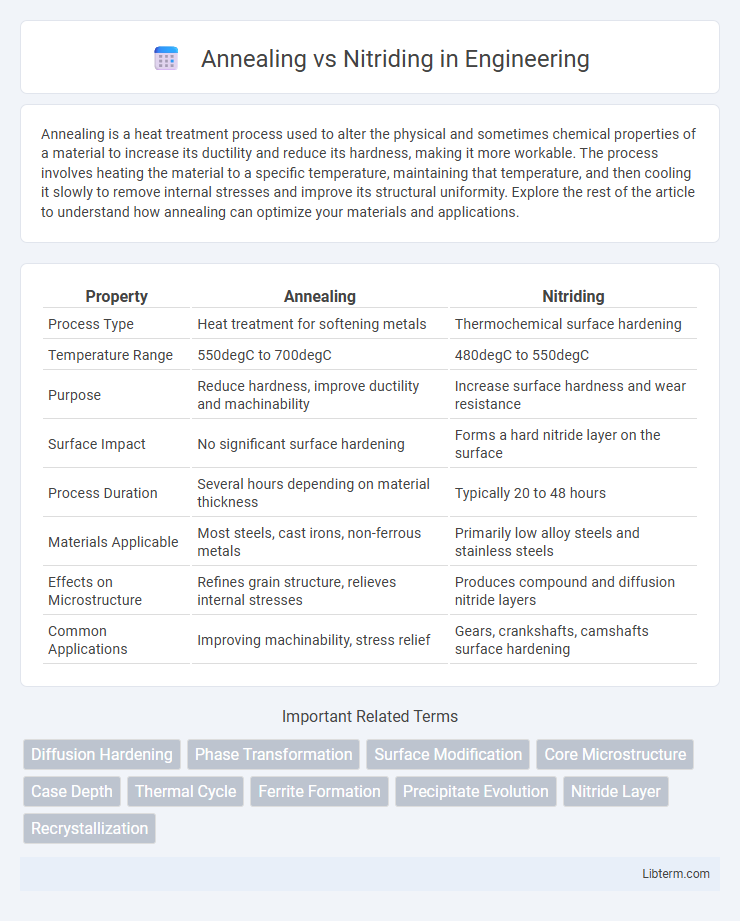

| Property | Annealing | Nitriding |

|---|---|---|

| Process Type | Heat treatment for softening metals | Thermochemical surface hardening |

| Temperature Range | 550degC to 700degC | 480degC to 550degC |

| Purpose | Reduce hardness, improve ductility and machinability | Increase surface hardness and wear resistance |

| Surface Impact | No significant surface hardening | Forms a hard nitride layer on the surface |

| Process Duration | Several hours depending on material thickness | Typically 20 to 48 hours |

| Materials Applicable | Most steels, cast irons, non-ferrous metals | Primarily low alloy steels and stainless steels |

| Effects on Microstructure | Refines grain structure, relieves internal stresses | Produces compound and diffusion nitride layers |

| Common Applications | Improving machinability, stress relief | Gears, crankshafts, camshafts surface hardening |

Introduction to Annealing and Nitriding

Annealing is a heat treatment process that softens metal by heating it to a specific temperature and then cooling it slowly, enhancing ductility and reducing hardness. Nitriding involves diffusing nitrogen into the surface of steel at elevated temperatures, improving hardness, wear resistance, and fatigue strength without altering the core properties. Both processes optimize metal performance, with annealing focusing on internal structure refinement and nitriding targeting surface enhancement.

Definition and Process Overview

Annealing is a heat treatment process in which a metal is heated to a specific temperature and then slowly cooled to soften the material, improve ductility, and relieve internal stresses. Nitriding is a surface-hardening process that introduces nitrogen into the surface layer of a metal at elevated temperatures, forming hard nitrides to enhance wear resistance and fatigue strength. The annealing process involves controlled heating and gradual cooling, while nitriding requires a nitrogen-rich environment, often performed in gas, plasma, or salt bath mediums.

Key Differences Between Annealing and Nitriding

Annealing is a heat treatment process that softens metal by heating it to a specific temperature and then slowly cooling to improve ductility and reduce hardness, while nitriding is a surface hardening technique that diffuses nitrogen into the metal's surface at lower temperatures without altering the core properties. Annealing primarily alters the internal microstructure to relieve stresses and improve machinability, whereas nitriding enhances surface hardness, wear resistance, and fatigue strength through the formation of hard nitrides. The key difference lies in annealing's bulk softening effect versus nitriding's focused surface hardening and improved corrosion resistance.

Materials Suitable for Annealing vs Nitriding

Annealing is suitable for a wide range of metals including steel, aluminum, copper, and brass, as it primarily softens the material and improves ductility by relieving internal stresses. Nitriding is specifically applied to high-alloy steels such as chromium, molybdenum, and aluminum steels, enhancing surface hardness through nitrogen diffusion without altering the core properties. Materials for nitriding require a compatible alloy composition for effective nitrogen absorption, whereas annealing accommodates various metals for improving machinability and mechanical performance.

Process Temperatures and Atmospheres

Annealing typically occurs at temperatures ranging from 500degC to 850degC in controlled atmospheres such as inert gases, vacuum, or reducing environments to prevent oxidation and achieve uniform softening. Nitriding operates at lower temperatures, usually between 500degC and 580degC, within nitrogen-rich atmospheres or ammonia gas to enable nitrogen diffusion into the metal surface, enhancing hardness and wear resistance. The precise control of temperature and atmosphere during both processes is critical to optimizing microstructural transformations and surface properties in steel components.

Mechanical Properties Achieved

Annealing improves ductility and reduces hardness by softening the metal's microstructure, enhancing machinability and stress relief without significantly increasing tensile strength. Nitriding significantly enhances surface hardness and wear resistance through the formation of hard nitrides, leading to improved fatigue strength and corrosion resistance while maintaining core toughness. Both processes tailor mechanical properties: annealing optimizes ductility and formability, whereas nitriding enhances surface mechanical performance and longevity.

Surface Hardness and Core Toughness

Annealing softens the metal by heating and slow cooling, enhancing core toughness but reducing surface hardness. Nitriding introduces nitrogen into the metal surface, significantly increasing surface hardness while maintaining core toughness without altering the bulk material properties. This makes nitriding ideal for applications requiring wear resistance and fatigue strength along with a tough core.

Typical Applications in Industry

Annealing is widely employed in the automotive and aerospace industries to improve ductility and reduce hardness in steel components, enhancing machinability and stress relief during manufacturing processes. Nitriding is typically used in the tooling and gear manufacturing sectors, providing surface hardening and wear resistance for parts such as crankshafts, camshafts, and dies without affecting the core material's toughness. Both processes are critical in extending the service life of industrial parts under high stress and mechanical load conditions.

Advantages and Limitations of Each Process

Annealing enhances ductility and reduces internal stresses in metals, improving machinability and making it ideal for refining microstructure, though it may soften the material and reduce hardness. Nitriding significantly increases surface hardness and wear resistance by diffusing nitrogen into the steel, prolonging component life under high stress, but it requires precise control of temperature and time and is limited to materials with sufficient nitrogen affinity. Each process offers specific benefits: annealing improves overall material workability while nitriding excels in surface durability, with their selection dependent on the desired mechanical properties and application requirements.

Choosing the Right Heat Treatment Technique

Choosing the right heat treatment technique depends on the desired material properties and application requirements. Annealing is ideal for improving ductility, reducing hardness, and relieving internal stresses in metals, making it suitable for forming and machining processes. Nitriding enhances surface hardness and wear resistance by diffusing nitrogen into the steel surface, making it preferable for components subjected to high fatigue and wear conditions.

Annealing Infographic

libterm.com

libterm.com