Location tolerance refers to the allowable deviation between the intended and actual position of a component or feature in manufacturing and engineering. Precise location tolerance ensures parts fit and function correctly within assemblies, preventing misalignments that could lead to mechanical failure or decreased performance. Discover how understanding and applying location tolerance can improve Your design accuracy and manufacturing quality by reading the rest of this article.

Table of Comparison

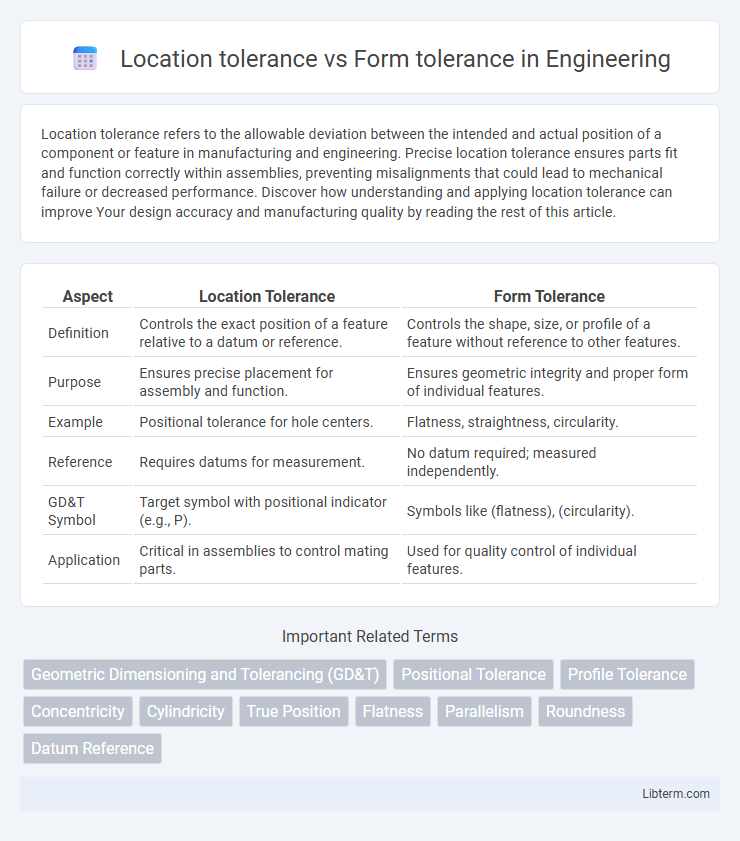

| Aspect | Location Tolerance | Form Tolerance |

|---|---|---|

| Definition | Controls the exact position of a feature relative to a datum or reference. | Controls the shape, size, or profile of a feature without reference to other features. |

| Purpose | Ensures precise placement for assembly and function. | Ensures geometric integrity and proper form of individual features. |

| Example | Positional tolerance for hole centers. | Flatness, straightness, circularity. |

| Reference | Requires datums for measurement. | No datum required; measured independently. |

| GD&T Symbol | Target symbol with positional indicator (e.g., P). | Symbols like (flatness), (circularity). |

| Application | Critical in assemblies to control mating parts. | Used for quality control of individual features. |

Introduction to Geometric Dimensioning and Tolerancing (GD&T)

Location tolerance controls the positional accuracy of features relative to a datums, ensuring parts fit and assemble correctly. Form tolerance governs the shape, such as flatness or straightness, without referring to other features, maintaining functional surface quality. Understanding both is crucial in Geometric Dimensioning and Tolerancing (GD&T) to achieve precise manufacturing and quality control.

Defining Location Tolerance

Location tolerance specifies the permissible variation in the exact position of a feature relative to its true or nominal location, ensuring that parts fit and function correctly within an assembly. It controls the spatial accuracy of features such as holes or slots by defining a boundary zone within which the feature's axis or center must lie. Unlike form tolerance, which governs the shape or surface irregularities of a feature, location tolerance targets the precise placement critical for mating and alignment of components.

Understanding Form Tolerance

Form tolerance controls the shape of individual features without considering their orientation or position, ensuring parts meet geometric criteria like flatness, straightness, or circularity. It focuses on the uniformity and consistency of the feature's surface, essential for proper fit and function in assemblies. Understanding form tolerance is crucial for maintaining the part's intended geometry independent of its location or alignment.

Key Differences Between Location and Form Tolerance

Location tolerance specifies the allowable deviation in the position of a feature relative to a true coordinate or datum, ensuring parts fit and function correctly in assembly. Form tolerance controls the shape of a feature, such as straightness, flatness, or roundness, without regard to its position. Key differences include location tolerance's emphasis on spatial placement accuracy, while form tolerance focuses solely on geometric shape consistency.

Importance of Location Tolerance in Manufacturing

Location tolerance is critical in manufacturing for ensuring precise placement of features, which directly affects the assembly fit and functional performance of a product. Unlike form tolerance that controls the shape of a single feature, location tolerance governs the exact position relative to other features, reducing errors during assembly and increasing product reliability. Maintaining strict location tolerance helps in minimizing rework costs, enhancing interchangeability, and meeting stringent industry standards such as ISO and ASME.

Role of Form Tolerance in Quality Control

Form tolerance plays a crucial role in quality control by ensuring the geometric accuracy of individual features, such as flatness, straightness, roundness, and cylindricity, independent of their location. This precision in shape directly impacts the functionality and aesthetics of the final product, reducing defects caused by form deviations. Strict enforcement of form tolerance helps maintain consistent manufacturing processes and enhances product reliability by minimizing variability in component geometry.

Common Symbols for Location and Form Tolerances

Location tolerance and form tolerance use distinct sets of symbols to specify geometric requirements on engineering drawings. Common location tolerance symbols include position ( with a crosshair), concentricity (two concentric circles), and symmetry (two parallel lines with a centerline), while form tolerance symbols feature straightness (a straight line), flatness (a parallelogram), circularity (a circle), and cylindricity (a cylinder). Understanding these symbols ensures precise control over part geometry by distinguishing between allowable deviations in feature location versus feature form.

Impact on Assembly and Functionality

Location tolerance directly influences the precise positioning of components, ensuring proper alignment and fit during assembly, which is critical for maintaining the intended functionality of mechanical systems. Form tolerance controls the shape and surface quality of individual parts, affecting how components interact and move relative to each other, which can prevent assembly issues such as binding or excessive wear. Both tolerances impact the overall product performance, but location tolerance primarily governs assembly accuracy, while form tolerance ensures component integrity and smooth operation.

Practical Examples: Location vs Form Tolerance

Location tolerance controls the position, orientation, or path of a feature relative to a datum, ensuring parts fit and function properly in assembly, such as locating holes on a flange to match mating components. Form tolerance governs the shape of individual features, like straightness or flatness, maintaining surface quality and mechanical function without reference to other parts, for example, ensuring a shaft's cylindrical form to prevent wear and vibration. Practical applications show location tolerance is critical when multiple parts interact, while form tolerance is essential for single-part functionality and manufacturing precision.

Best Practices for Applying Tolerances in Design

Location tolerance controls the exact position of features to ensure proper assembly and function, while form tolerance governs the shape, straightness, or flatness for part integrity. Best practices for applying tolerances in design emphasize specifying the loosest tolerance that still guarantees performance, reducing manufacturing costs and inspection complexity. Prioritizing critical features with tighter location tolerances and less critical ones with form tolerances optimizes both precision and cost efficiency.

Location tolerance Infographic

libterm.com

libterm.com