Binder jetting revolutionizes 3D printing by using a liquid binding agent to fuse powder materials layer by layer, creating complex parts with high precision and speed. This technology allows for cost-effective production of metal, sand, or ceramic components, ideal for rapid prototyping and small batch manufacturing. Explore the rest of the article to discover how binder jetting can enhance your manufacturing processes.

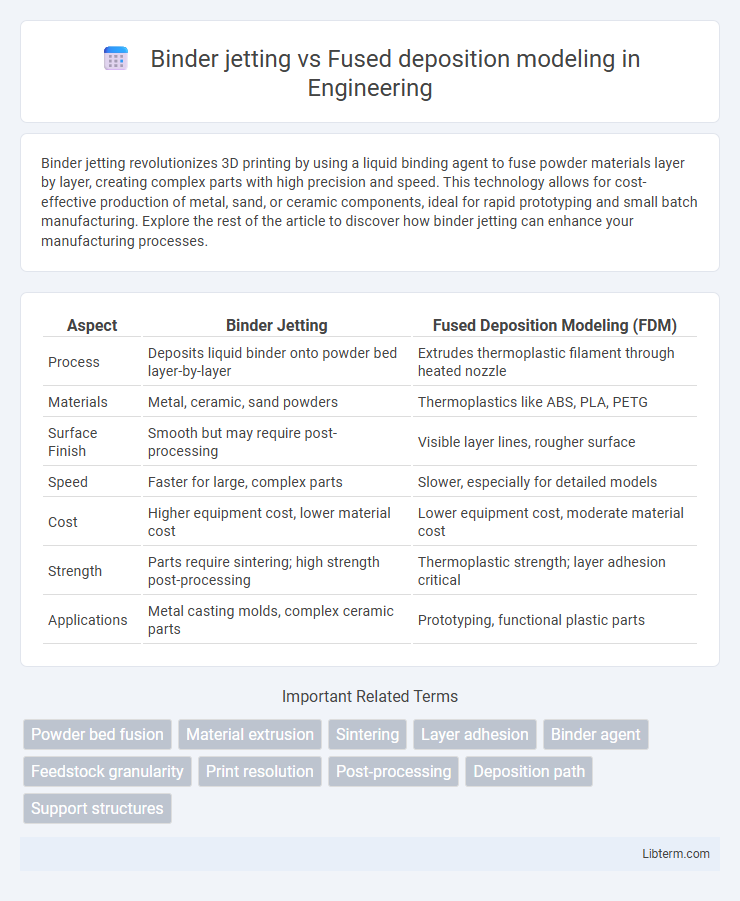

Table of Comparison

| Aspect | Binder Jetting | Fused Deposition Modeling (FDM) |

|---|---|---|

| Process | Deposits liquid binder onto powder bed layer-by-layer | Extrudes thermoplastic filament through heated nozzle |

| Materials | Metal, ceramic, sand powders | Thermoplastics like ABS, PLA, PETG |

| Surface Finish | Smooth but may require post-processing | Visible layer lines, rougher surface |

| Speed | Faster for large, complex parts | Slower, especially for detailed models |

| Cost | Higher equipment cost, lower material cost | Lower equipment cost, moderate material cost |

| Strength | Parts require sintering; high strength post-processing | Thermoplastic strength; layer adhesion critical |

| Applications | Metal casting molds, complex ceramic parts | Prototyping, functional plastic parts |

Introduction to Binder Jetting and Fused Deposition Modeling

Binder Jetting utilizes a liquid binding agent selectively deposited to bond powder particles layer-by-layer, enabling the production of complex geometries without the need for support structures. Fused Deposition Modeling (FDM) extrudes thermoplastic filaments through a heated nozzle, solidifying layers to build parts with high strength and durability. Both additive manufacturing techniques offer unique advantages in material variety and production speed, with Binder Jetting favoring metal and sand applications, while FDM excels in plastic prototyping and functional components.

Core Principles of Binder Jetting

Binder jetting operates by selectively depositing a liquid binding agent onto layers of powdered material, creating a solid part layer by layer without the need for high temperatures. This process contrasts with fused deposition modeling (FDM), which melts and extrudes thermoplastic filaments to build parts. Binder jetting allows for faster production speeds and can handle a wider range of materials, including metals, ceramics, and sand, enabling complex geometries and reduced thermal distortion.

Fundamentals of Fused Deposition Modeling

Fused Deposition Modeling (FDM) operates by extruding thermoplastic filaments through a heated nozzle, layer by layer, to build three-dimensional objects based on CAD designs. Unlike Binder Jetting, which uses a liquid binding agent to adhere powder particles, FDM relies on the precise melting and solidification of materials such as ABS, PLA, and PETG to create durable parts with strong mechanical properties. The controlled deposition and cooling process in FDM enables high accuracy and repeatability, making it ideal for prototyping and functional component manufacturing.

Materials Used in Binder Jetting vs FDM

Binder jetting primarily uses powdered materials such as metals, ceramics, and sand, allowing for high-density, full-color prints without requiring high-temperature processing. In contrast, Fused Deposition Modeling (FDM) utilizes thermoplastic filaments like ABS, PLA, and PETG, which are melted and extruded layer by layer to build parts. The material versatility in binder jetting supports complex geometries and multi-material composites, while FDM emphasizes accessibility and a broad range of plastic options for prototyping and functional parts.

Printing Speed and Efficiency Comparison

Binder jetting offers significantly higher printing speeds compared to fused deposition modeling (FDM) due to its layer-by-layer powder deposition and selective binding process, allowing rapid production of complex geometries without the need for support structures. FDM involves slower extrusion of thermoplastic filaments, resulting in longer build times, especially for intricate or large-scale parts. Efficiency in binder jetting also benefits from minimal post-processing and reduced material waste, whereas FDM frequently requires additional support removal and finishing steps, impacting overall production time.

Surface Quality and Resolution Differences

Binder jetting offers superior surface finish with smoother textures and finer details due to its liquid binding agent, enabling higher resolution in complex geometries. Fused deposition modeling (FDM) typically produces rougher surfaces with visible layer lines and lower resolution because it extrudes thermoplastic filaments in thicker layers. The difference in surface quality and resolution significantly impacts post-processing requirements and application suitability for detailed prototypes or functional parts.

Mechanical Properties of Printed Parts

Binder jetting produces parts with lower density and mechanical strength due to its layer-by-layer powder bonding process, resulting in higher porosity and reduced tensile strength compared to fused deposition modeling (FDM). FDM uses thermoplastic extrusion, creating stronger interlayer bonding and better impact resistance, yielding parts with superior tensile and flexural strength. However, binder jetting enables faster printing of complex geometries with post-processing infiltration to improve mechanical properties, while FDM offers more consistent mechanical performance in functional prototypes.

Cost Analysis: Binder Jetting vs FDM

Binder jetting generally involves higher initial equipment costs compared to Fused Deposition Modeling (FDM), but it offers faster production speeds and lower material expenses for large-volume runs. FDM printers are more affordable and accessible for prototyping and small batch manufacturing, yet material costs can increase significantly with high-detail or multi-material prints. Evaluating total cost of ownership requires considering build volume, part complexity, material consumption, and post-processing requirements for both technologies.

Ideal Applications for Each Technology

Binder jetting excels in producing complex metal parts and large-scale prototypes with intricate geometries, making it ideal for aerospace, automotive, and industrial tooling applications. Fused deposition modeling (FDM) is best suited for rapid prototyping, functional testing, and small-scale production using thermoplastic materials, frequently applied in consumer product development and educational models. Each technology's suitability depends on factors such as material compatibility, resolution requirements, and production volume.

Future Trends in Additive Manufacturing

Binder jetting is advancing toward higher-speed production and multi-material capabilities, enabling complex geometries and large-scale manufacturing with metal and ceramic parts. Fused deposition modeling is evolving through enhanced material formulations and improved printer precision, expanding applications in customized prototyping and functional end-use components. Both technologies are increasingly integrating AI-driven process optimization and sustainable, recyclable materials to accelerate innovation and reduce environmental impact in additive manufacturing.

Binder jetting Infographic

libterm.com

libterm.com