Critical damping occurs when a system returns to equilibrium as quickly as possible without oscillating, providing the fastest stabilization in mechanical or electrical systems. This precise damping level prevents overshooting and ensures optimal system performance in applications like shock absorbers and circuit design. Explore the article to understand how critical damping can enhance your system's efficiency and stability.

Table of Comparison

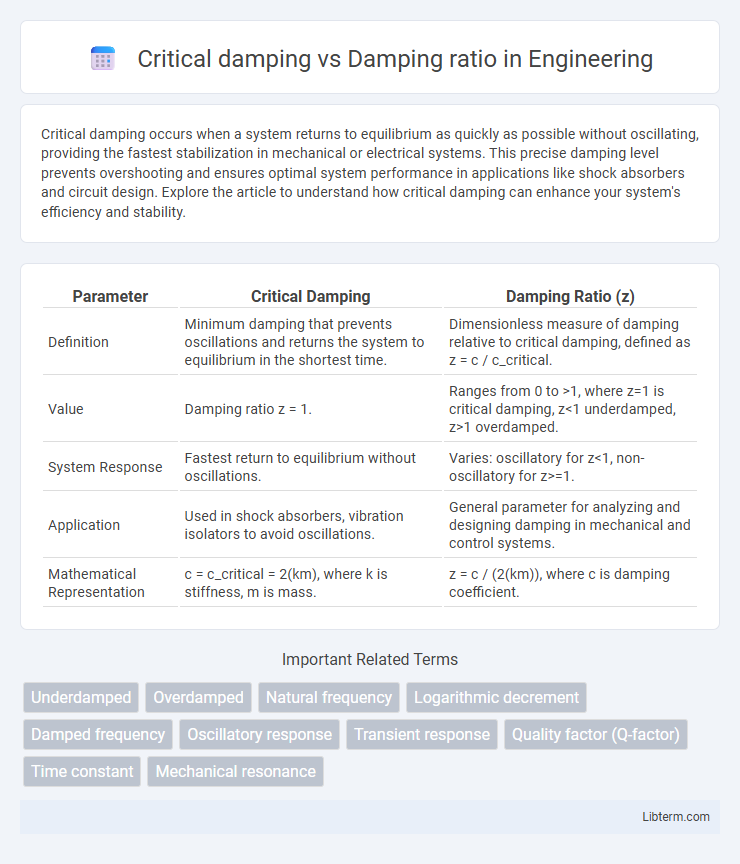

| Parameter | Critical Damping | Damping Ratio (z) |

|---|---|---|

| Definition | Minimum damping that prevents oscillations and returns the system to equilibrium in the shortest time. | Dimensionless measure of damping relative to critical damping, defined as z = c / c_critical. |

| Value | Damping ratio z = 1. | Ranges from 0 to >1, where z=1 is critical damping, z<1 underdamped, z>1 overdamped. |

| System Response | Fastest return to equilibrium without oscillations. | Varies: oscillatory for z<1, non-oscillatory for z>=1. |

| Application | Used in shock absorbers, vibration isolators to avoid oscillations. | General parameter for analyzing and designing damping in mechanical and control systems. |

| Mathematical Representation | c = c_critical = 2(km), where k is stiffness, m is mass. | z = c / (2(km)), where c is damping coefficient. |

Introduction to Damping in Mechanical Systems

Damping in mechanical systems controls oscillations by dissipating energy, with the damping ratio quantifying this effect relative to critical damping. Critical damping represents the precise point where a system returns to equilibrium without oscillating, occurring when the damping ratio equals one. Understanding the distinction between critical damping and other damping ratios is essential for optimizing system stability and response time.

What is Critical Damping?

Critical damping occurs when a system returns to equilibrium as quickly as possible without oscillating, corresponding to a damping ratio of exactly 1. It represents the boundary between underdamped (damping ratio less than 1) and overdamped (damping ratio greater than 1) systems, ensuring the fastest possible stabilization without overshoot. Achieving critical damping is essential in engineering applications such as shock absorbers and vibration control systems to prevent prolonged oscillations and ensure rapid system response.

Understanding the Damping Ratio

The damping ratio quantifies the extent of damping in a system relative to critical damping, with a ratio of 1 indicating critical damping where the system returns to equilibrium in the shortest time without oscillating. Values less than 1 represent underdamping, causing oscillatory behavior, while values greater than 1 indicate overdamping, where the system returns to equilibrium slowly without oscillations. Understanding the damping ratio is essential for designing systems with desired transient responses and stability characteristics.

Mathematical Representation of Damping

Critical damping occurs when the damping ratio (z) equals 1, indicating the system returns to equilibrium as quickly as possible without oscillating. The damping ratio is mathematically defined as z = c / (2(mk)), where c is the damping coefficient, m is the mass, and k is the stiffness. This dimensionless parameter quantifies the level of damping relative to the critical damping value c_critical = 2(mk).

Types of Damping: Underdamped, Critically Damped, Overdamped

Critical damping occurs at a damping ratio of exactly 1, representing the threshold between oscillatory and non-oscillatory system responses. Underdamped systems have a damping ratio less than 1, resulting in oscillations that gradually decay over time, while overdamped systems have a damping ratio greater than 1, causing the system to return to equilibrium without oscillations but more slowly than in the critically damped case. These damping types are crucial in engineering for predicting the dynamic behavior of mechanical and control systems.

Critical Damping vs Damping Ratio: Key Differences

Critical damping occurs when the damping ratio equals 1, representing the threshold at which a system returns to equilibrium in the shortest time without oscillating. The damping ratio is a dimensionless measure describing how oscillations in a system decay after a disturbance, with values less than 1 indicating underdamping, greater than 1 indicating overdamping, and exactly 1 indicating critical damping. Key differences lie in their definitions and effects: critical damping is a specific condition characterized by a precise damping ratio value, while the damping ratio itself is a parameter that quantifies overall damping behavior across a range of conditions.

Practical Examples of Critical Damping

Critical damping occurs when the damping ratio equals 1, providing the fastest return to equilibrium without oscillation, as seen in automotive shock absorbers designed to quickly stabilize vehicle suspension after a bump. In Precision instruments like galvanometers, critical damping prevents needle oscillation, allowing accurate and rapid readings. Understanding critical damping helps engineers design systems like building sway dampers, which minimize oscillations during earthquakes for structural safety.

The Role of Damping Ratio in System Behavior

The damping ratio is a dimensionless measure that quantifies the level of damping in a system relative to its critical damping, directly influencing the system's oscillatory response and stability. When the damping ratio equals one, the system experiences critical damping, returning to equilibrium without oscillating, which is ideal for avoiding overshoot and minimizing settling time. Values below one lead to underdamped behavior with oscillations, while values above one result in overdamped behavior with slower response times, making the damping ratio essential for predicting and controlling dynamic system behavior.

Applications of Damping in Engineering and Design

Critical damping occurs at a damping ratio of exactly 1, where a system returns to equilibrium as quickly as possible without oscillating, ideal for applications like automotive suspension and earthquake-resistant structures requiring rapid stability. Systems with damping ratios less than 1 experience underdamping, useful in vibration isolation and dynamic systems where some oscillation is acceptable or beneficial. Engineering design leverages precise control of damping ratios to optimize performance, noise reduction, and longevity in mechanical components, civil structures, and aerospace systems.

Conclusion: Choosing the Right Damping for Your System

Critical damping occurs when the damping ratio equals one, providing the fastest return to equilibrium without oscillations, ideal for systems requiring quick stabilization. Selecting a damping ratio less than one results in underdamping, causing oscillations but faster response, while a ratio greater than one leads to overdamping, yielding slower response without oscillations. The optimal damping choice depends on the specific application needs, balancing speed and stability to achieve desired system performance.

Critical damping Infographic

libterm.com

libterm.com