Surface texture significantly influences the performance and aesthetics of materials by affecting friction, wear resistance, and visual appeal. Understanding the key parameters such as roughness, waviness, and lay helps in optimizing manufacturing processes and quality control. Explore the rest of the article to learn how to enhance your products with precise surface texture management.

Table of Comparison

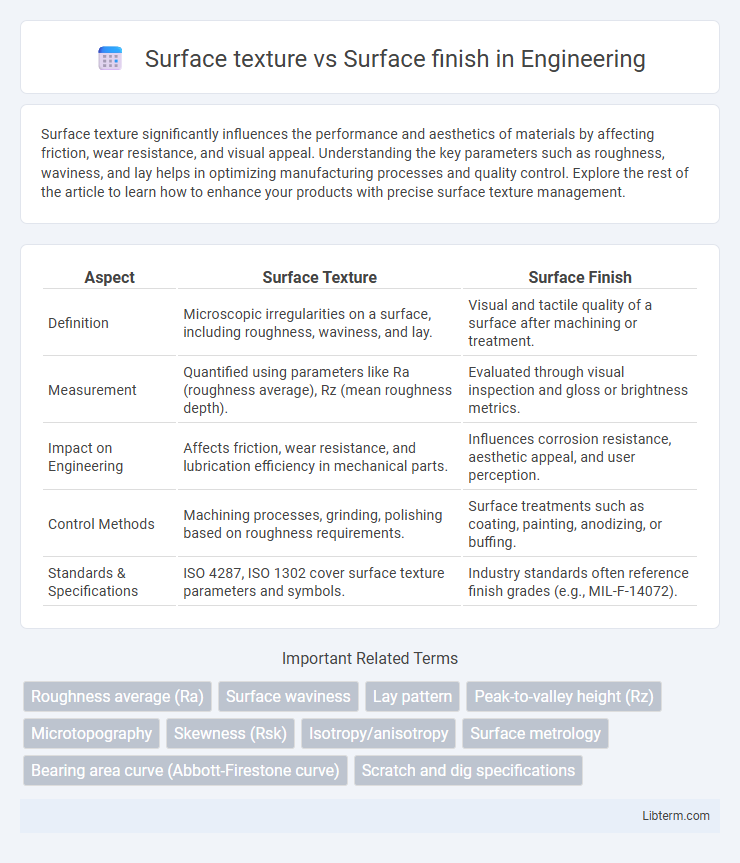

| Aspect | Surface Texture | Surface Finish |

|---|---|---|

| Definition | Microscopic irregularities on a surface, including roughness, waviness, and lay. | Visual and tactile quality of a surface after machining or treatment. |

| Measurement | Quantified using parameters like Ra (roughness average), Rz (mean roughness depth). | Evaluated through visual inspection and gloss or brightness metrics. |

| Impact on Engineering | Affects friction, wear resistance, and lubrication efficiency in mechanical parts. | Influences corrosion resistance, aesthetic appeal, and user perception. |

| Control Methods | Machining processes, grinding, polishing based on roughness requirements. | Surface treatments such as coating, painting, anodizing, or buffing. |

| Standards & Specifications | ISO 4287, ISO 1302 cover surface texture parameters and symbols. | Industry standards often reference finish grades (e.g., MIL-F-14072). |

Introduction to Surface Texture and Surface Finish

Surface texture describes the micro-geometric deviations on a material's surface, including roughness, waviness, and lay patterns. Surface finish refers to the measurable qualities of texture, often quantified by parameters such as Ra (average roughness) and Rz (maximum height). These characteristics influence the performance, wear resistance, and aesthetic quality of machined or treated surfaces.

Defining Surface Texture: Key Characteristics

Surface texture refers to the three-dimensional topographical features of a surface, encompassing roughness, waviness, and lay, which collectively define its micro-geometric characteristics. Key parameters in surface texture include amplitude measurements like Ra (average roughness) and Rz (mean peak-to-valley height), along with spatial features such as wavelength and direction. Understanding these characteristics is essential for predicting a component's functional performance, including friction, wear, and lubrication behavior.

Understanding Surface Finish: What It Means

Surface finish refers to the topographical features of a surface, including its roughness, waviness, and lay, which directly impact product performance and aesthetics. It quantifies how smooth or textured a surface is, influencing factors like friction, wear, and paint adhesion in manufacturing and engineering. Understanding surface finish is essential for ensuring component functionality, durability, and quality control in various industrial applications.

Surface Texture vs Surface Finish: Core Differences

Surface texture refers to the three-dimensional topography of a surface, including its roughness, waviness, and lay, which are critical for functional performance and tribological properties. Surface finish, on the other hand, focuses on the final appearance and quality of the surface after manufacturing processes, often measured by parameters like Ra (average roughness) and visual smoothness. The core difference lies in surface texture describing the inherent microscopic geometric features, while surface finish emphasizes the overall aesthetic and tactile quality achieved through finishing techniques.

Importance of Surface Texture in Engineering Applications

Surface texture directly influences the performance, durability, and functionality of engineering components by affecting friction, wear, and lubrication properties. Precise control of surface texture enhances fatigue resistance and corrosion behavior, critical in aerospace, automotive, and medical device manufacturing. Advanced measurement techniques like profilometry ensure optimal surface characteristics, improving reliability and operational efficiency in high-precision engineering applications.

Role of Surface Finish in Product Performance

Surface finish plays a critical role in product performance by directly influencing friction, wear resistance, and sealing capabilities, which ultimately affect the durability and efficiency of mechanical components. A finely controlled surface finish can enhance lubrication retention, reduce stress concentrators, and improve corrosion resistance, leading to longer service life and better operational reliability. Unlike surface texture, which describes the geometric features of a surface, surface finish encompasses the overall quality and smoothness that determine functional performance in engineering applications.

Measurement Techniques for Surface Texture

Surface texture measurement techniques include profilometry, where contact or non-contact instruments trace the surface to capture roughness, waviness, and lay parameters with high precision. Optical methods such as laser scanning confocal microscopy and white light interferometry provide non-destructive, high-resolution surface topography data ideal for analyzing microscale texture variations. These advanced measurement tools enhance surface characterization beyond traditional surface finish assessments by detailing surface irregularities critical to performance and functionality.

Methods for Achieving Optimal Surface Finish

Surface texture and surface finish are distinct yet interconnected aspects of a material's surface, where surface texture involves the micro-scale variations and surface finish refers to the overall smoothness or appearance achieved through finishing processes. Methods for achieving optimal surface finish include precision machining, abrasive polishing, and chemical etching, which refine surface irregularities and improve functional performance. Advanced techniques such as laser surface texturing and superfinishing further enhance surface quality by providing controlled modification at micro and nano levels, critical for applications in aerospace, automotive, and medical devices.

Impact of Material Choice on Texture and Finish

Material choice significantly affects surface texture and finish, as harder materials typically resist deformation, resulting in smoother surfaces. Softer materials may exhibit rougher textures due to increased tool marks and material displacement during machining. The intrinsic properties of materials--such as hardness, ductility, and grain structure--directly influence the achievable finish quality and functional characteristics of the final product.

Choosing the Right Surface Quality for Your Application

Surface texture refers to the micro-scale variations in the surface profile, including roughness, waviness, and lay, while surface finish encompasses the overall appearance and tactile quality of a surface. Choosing the right surface quality for your application requires understanding specific functional requirements such as wear resistance, friction, and aesthetic appeal, which are directly influenced by surface texture parameters like Ra (roughness average) and Rz (mean roughness depth). Optimizing surface finish ensures enhanced performance, durability, and manufacturability in industries ranging from aerospace to medical devices, where precise control over texture is critical.

Surface texture Infographic

libterm.com

libterm.com