Steady flow refers to a fluid motion where the velocity at each point remains constant over time, ensuring predictable and uniform behavior in systems like pipelines and airflows. This condition is crucial for efficient design and analysis in engineering disciplines to maintain consistent performance and avoid turbulence. Explore the rest of the article to understand how steady flow impacts various applications and your projects.

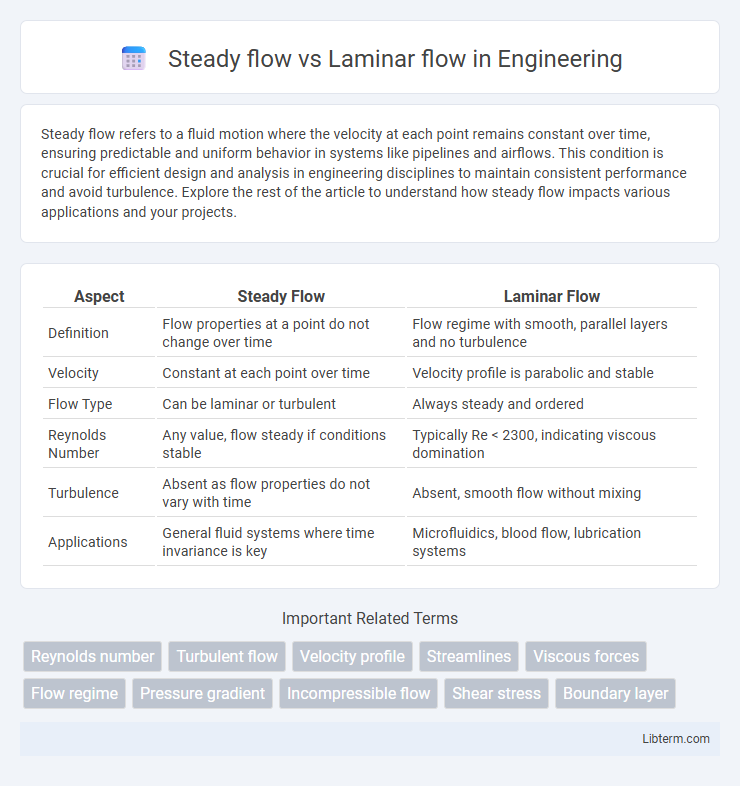

Table of Comparison

| Aspect | Steady Flow | Laminar Flow |

|---|---|---|

| Definition | Flow properties at a point do not change over time | Flow regime with smooth, parallel layers and no turbulence |

| Velocity | Constant at each point over time | Velocity profile is parabolic and stable |

| Flow Type | Can be laminar or turbulent | Always steady and ordered |

| Reynolds Number | Any value, flow steady if conditions stable | Typically Re < 2300, indicating viscous domination |

| Turbulence | Absent as flow properties do not vary with time | Absent, smooth flow without mixing |

| Applications | General fluid systems where time invariance is key | Microfluidics, blood flow, lubrication systems |

Introduction to Fluid Flow Types

Steady flow refers to fluid motion where velocity at any given point remains constant over time, exemplified by consistent flow in pipelines. Laminar flow is characterized by smooth, orderly layers of fluid sliding past each other with minimal mixing, typically occurring at low Reynolds numbers below 2,300. Both flow types are fundamental in analyzing fluid dynamics for engineering applications, impacting pressure drop and heat transfer rates.

Definition of Steady Flow

Steady flow is characterized by fluid properties such as velocity, pressure, and density remaining constant at any given point over time, ensuring predictable and consistent behavior. This definition contrasts with laminar flow, which describes a flow regime where fluid moves in smooth, orderly layers without turbulence. Understanding steady flow is essential for applications in fluid dynamics, hydraulic systems, and engineering design where stability and uniformity of flow conditions are critical.

Definition of Laminar Flow

Laminar flow is characterized by smooth, parallel layers of fluid that move in a steady, orderly manner without disruption between the layers. This flow type is defined by low Reynolds numbers, typically below 2,000, indicating minimal mixing and turbulence within the fluid. Steady flow, on the other hand, refers to a flow regime where fluid properties at any point remain constant over time but can be either laminar or turbulent depending on the specific conditions.

Key Differences Between Steady and Laminar Flow

Steady flow refers to fluid motion where velocity at any point remains constant over time, whereas laminar flow describes a smooth, orderly fluid motion characterized by parallel layers with no disruption between them. Steady flow can be either laminar or turbulent, but laminar flow specifically involves low Reynolds numbers (typically below 2000), resulting in minimal mixing and predictable fluid behavior. In contrast, steady flow emphasizes temporal constancy, while laminar flow focuses on spatial fluid organization and flow regime stability.

Characteristics of Steady Flow

Steady flow is characterized by fluid properties such as velocity, pressure, and density remaining constant at any given point over time, ensuring predictable behavior in fluid mechanics. This contrasts with laminar flow, where fluid moves in smooth layers but can be unsteady if properties fluctuate with time. The predictability of steady flow simplifies analysis in engineering applications like pipe flow and aerodynamics.

Characteristics of Laminar Flow

Laminar flow is characterized by smooth, parallel layers of fluid that flow in an orderly fashion with minimal mixing between layers, resulting in a constant velocity profile at any given cross-section. It typically occurs at low Reynolds numbers, where viscous forces dominate over inertial forces, maintaining stability and predictability in the flow pattern. The flow exhibits low turbulence, low energy loss, and a linear velocity gradient across the channel or pipe.

Factors Affecting Steady and Laminar Flow

Steady flow occurs when fluid velocity at a point remains constant over time, influenced by factors like constant pressure gradients and stable boundary conditions. Laminar flow is characterized by smooth, parallel fluid layers with minimal mixing, affected by low Reynolds numbers, fluid viscosity, and flow velocity. Surface roughness, pipe diameter, and temperature also significantly impact the transition between steady and laminar flow regimes.

Practical Examples of Each Flow Type

Steady flow occurs in rivers where water velocity and direction remain constant, such as in irrigation channels ensuring consistent water delivery. Laminar flow is observed in medical applications like intravenous drip systems, where smooth, orderly fluid motion prevents turbulence and allows precise medication dosing. Both flow types are critical in engineering design, influencing efficiency and safety in hydraulic and biomedical systems.

Applications in Engineering and Industry

Steady flow ensures consistent fluid velocity and pressure over time, making it essential for accurate performance in hydraulic systems, pipeline transport, and HVAC design where predictability improves efficiency and control. Laminar flow, characterized by smooth, layered fluid movement, is critical in microfluidics, chemical reactors, and aerodynamics to minimize turbulence, reduce energy loss, and enhance precision in mixing and heat transfer. Engineering applications benefit from steady laminar flow conditions to optimize system stability, reduce wear, and improve process reliability across various industrial sectors.

Summary and Conclusion

Steady flow maintains constant velocity and pressure at any given point over time, while laminar flow features smooth, orderly fluid motion with parallel layers and minimal mixing. Steady flow can be laminar or turbulent depending on factors like velocity and viscosity, but laminar flow specifically refers to the flow regime characterized by low Reynolds numbers where viscous forces dominate. Understanding these distinctions is essential for optimizing fluid dynamics in engineering applications such as pipeline design, aerodynamics, and chemical processes.

Steady flow Infographic

libterm.com

libterm.com