Fatigue can significantly impair your daily functioning, resulting in decreased concentration, reduced motivation, and weakened physical performance. Recognizing the underlying causes, such as sleep disorders, nutritional deficiencies, or chronic illness, is crucial for effective management. Explore the article to uncover practical strategies and lifestyle adjustments to combat fatigue and restore your vitality.

Table of Comparison

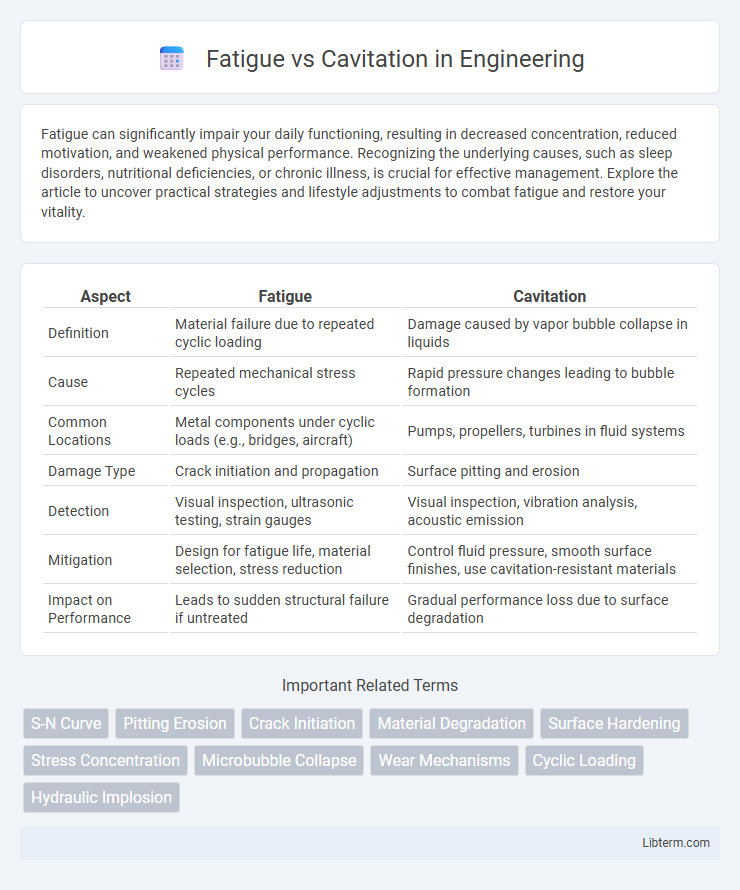

| Aspect | Fatigue | Cavitation |

|---|---|---|

| Definition | Material failure due to repeated cyclic loading | Damage caused by vapor bubble collapse in liquids |

| Cause | Repeated mechanical stress cycles | Rapid pressure changes leading to bubble formation |

| Common Locations | Metal components under cyclic loads (e.g., bridges, aircraft) | Pumps, propellers, turbines in fluid systems |

| Damage Type | Crack initiation and propagation | Surface pitting and erosion |

| Detection | Visual inspection, ultrasonic testing, strain gauges | Visual inspection, vibration analysis, acoustic emission |

| Mitigation | Design for fatigue life, material selection, stress reduction | Control fluid pressure, smooth surface finishes, use cavitation-resistant materials |

| Impact on Performance | Leads to sudden structural failure if untreated | Gradual performance loss due to surface degradation |

Understanding Fatigue and Cavitation

Fatigue refers to the progressive and localized structural damage that occurs when a material undergoes repeated loading cycles, leading to crack initiation and eventual failure. Cavitation is the formation and collapse of vapor bubbles in a liquid near a solid surface, causing shock waves that can erode materials. Understanding fatigue involves analyzing stress concentration, load frequency, and material properties, while understanding cavitation requires studying fluid dynamics, vapor pressure, and bubble collapse effects on surfaces.

Definitions: What Are Fatigue and Cavitation?

Fatigue refers to the progressive structural damage that occurs in materials subjected to cyclic loading, leading to the initiation and growth of cracks over time. Cavitation is the formation and collapse of vapor bubbles in a liquid when local pressure drops below the vapor pressure, causing shock waves that can erode material surfaces. Both phenomena result in material degradation but stem from different physical mechanisms--fatigue arises from repeated mechanical stress, while cavitation is driven by fluid dynamic pressure fluctuations.

Causes of Fatigue in Engineering Materials

Fatigue in engineering materials primarily stems from cyclic loading, causing microscopic cracks to initiate and propagate under repeated stress variations below the material's ultimate tensile strength. Surface imperfections, corrosion, and residual stresses intensify crack growth, leading to eventual structural failure. Unlike cavitation, which involves vapor bubble collapse in fluids causing localized damage, fatigue originates intrinsically within the solid material due to mechanical stress cycles.

Mechanisms Behind Cavitation Damage

Cavitation damage occurs when vapor bubbles form and collapse rapidly on a material surface, causing intense localized shock waves and microjets that erode the material. The mechanism involves cyclic pressure fluctuations leading to nucleation, growth, and violent implosion of bubbles, generating high stress concentrations that exceed the material's strength. This dynamic process differs from fatigue, which results from repeated mechanical loading causing crack initiation and propagation over time without the involvement of vapor bubble collapse.

Key Differences Between Fatigue and Cavitation

Fatigue refers to the progressive structural damage caused by cyclic loading and repeated stress over time, whereas cavitation results from vapor bubble formation and collapse in a fluid, causing localized surface damage. Fatigue damage typically manifests as crack initiation and propagation due to mechanical stress, while cavitation damage appears as pitting and material erosion on submerged surfaces. The primary distinction lies in fatigue being driven by mechanical stress cycles, whereas cavitation is a fluid dynamic phenomenon causing impact erosion.

Common Signs and Symptoms of Fatigue Failure

Fatigue failure typically manifests through common signs such as the appearance of surface cracks, which propagate over time under cyclic loading, leading to eventual fracture. Early symptoms include microscopic fissures, localized deformation, and rough, irregular fracture surfaces often displaying striations. Recognizing these indicators is essential for differentiating fatigue failure from cavitation damage, which generally involves pitting and material loss due to vapor bubble collapse rather than crack propagation.

How Cavitation Affects Material Surfaces

Cavitation produces intense localized pressure fluctuations that cause repeated formation and collapse of vapor bubbles, leading to surface pitting and micro-cracks on materials. This process accelerates surface degradation by removing protective coatings and creating stress concentrations that promote fatigue failure. Continuous cavitation exposure results in significant loss of material integrity and reduced lifespan of components.

Prevention and Mitigation Strategies

Fatigue in mechanical components can be mitigated through proper material selection, regular inspections, and stress-relief treatments to prevent crack initiation and propagation. Cavitation prevention involves optimizing fluid flow conditions, maintaining proper pressure levels, and using cavitation-resistant materials such as stainless steel or specialized coatings. Implementing vibration damping, controlling operational loads, and ensuring hydraulic system cleanliness also significantly reduce the risk and impact of both fatigue and cavitation damage.

Industries Most Affected by Fatigue and Cavitation

Fatigue predominantly impacts aerospace, automotive, and structural engineering industries where cyclic stresses cause material degradation over time, leading to cracks and potential failure. Cavitation severely affects marine, hydraulic, and pump industries by causing vapor bubble collapse that erodes metal surfaces, reducing equipment lifespan and efficiency. Both phenomena demand rigorous monitoring and maintenance protocols to prevent costly downtimes and ensure operational safety.

Future Research Directions and Innovations

Future research directions in fatigue vs cavitation emphasize the development of advanced materials with enhanced resistance to mechanical and acoustic stresses to improve durability. Innovations in real-time monitoring technologies using AI-driven sensors enable early detection and differentiation of fatigue cracks from cavitation damage in critical structures. Exploring nanostructured coatings and surface treatments shows significant potential for minimizing cavitation erosion while simultaneously increasing fatigue life in marine and hydraulic machinery components.

Fatigue Infographic

libterm.com

libterm.com