A four-bar is a concise musical phrase often used to establish rhythm, melody, or harmony within a composition. This fundamental structure forms the backbone of many genres, providing a recognizable and repeatable segment that drives the music forward. Explore the rest of the article to uncover how four-bar patterns can enhance your music production and creativity.

Table of Comparison

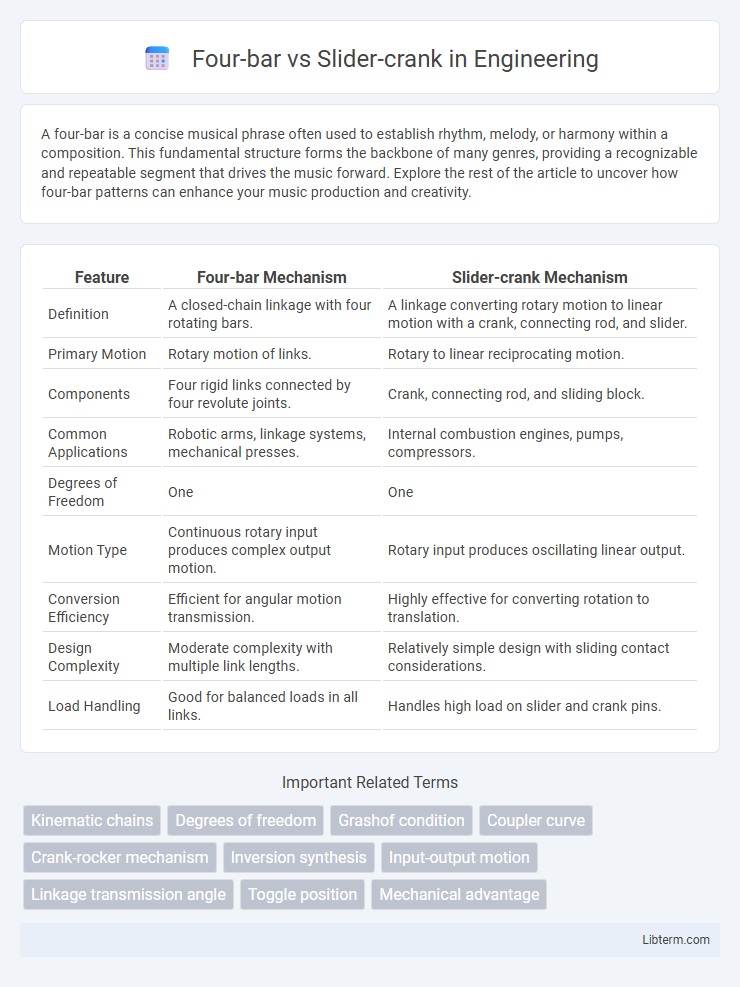

| Feature | Four-bar Mechanism | Slider-crank Mechanism |

|---|---|---|

| Definition | A closed-chain linkage with four rotating bars. | A linkage converting rotary motion to linear motion with a crank, connecting rod, and slider. |

| Primary Motion | Rotary motion of links. | Rotary to linear reciprocating motion. |

| Components | Four rigid links connected by four revolute joints. | Crank, connecting rod, and sliding block. |

| Common Applications | Robotic arms, linkage systems, mechanical presses. | Internal combustion engines, pumps, compressors. |

| Degrees of Freedom | One | One |

| Motion Type | Continuous rotary input produces complex output motion. | Rotary input produces oscillating linear output. |

| Conversion Efficiency | Efficient for angular motion transmission. | Highly effective for converting rotation to translation. |

| Design Complexity | Moderate complexity with multiple link lengths. | Relatively simple design with sliding contact considerations. |

| Load Handling | Good for balanced loads in all links. | Handles high load on slider and crank pins. |

Introduction to Four-Bar and Slider-Crank Mechanisms

Four-bar and slider-crank mechanisms are fundamental components in mechanical systems, widely used for converting motion and force. The four-bar mechanism consists of four rigid bars connected by pivot joints in a closed loop, enabling complex rotary and oscillatory motions. The slider-crank mechanism combines rotational and linear movements by linking a crank, connecting rod, and a sliding element, often used in engines and pumps for efficient motion transfer.

Fundamental Concepts and Definitions

The four-bar mechanism consists of four rigid links connected by four rotating pairs forming a closed loop, used widely for motion transfer and synthesis in mechanical systems. The slider-crank mechanism, a specific type of four-bar linkage, includes one sliding pair replacing a rotating pair, converting rotational motion into linear reciprocating motion or vice versa. Fundamental to understanding these mechanisms is grasping their link classifications, pair types, and degrees of freedom, which determine their motion capabilities and applications in engines, pumps, and robotic arms.

Structural Differences Between Four-Bar and Slider-Crank

The four-bar mechanism consists of four rigid links connected by four rotary pairs, forming a closed loop with purely rotational motion at each joint. In contrast, the slider-crank mechanism replaces one rotary pair with a prismatic pair, allowing linear sliding motion of the slider link. This key structural difference enables the slider-crank to convert rotational motion into linear motion, while the four-bar mechanism primarily produces complex rotational output paths.

Kinematic Analysis of Four-Bar Mechanisms

Four-bar mechanisms consist of four rigid links connected by rotary pairs, enabling complex planar motion and force transmission, essential for robotic arms and automotive suspensions. Kinematic analysis of four-bar linkages involves determining angular displacement, velocity, and acceleration of each link using loop-closure equations and vector algebra, providing precise motion prediction. Compared to slider-crank mechanisms, four-bars offer diverse path generation and smoother transmission angles, making them favorable in applications requiring variable motion profiles and load distribution.

Kinematic Analysis of Slider-Crank Mechanisms

Kinematic analysis of slider-crank mechanisms involves studying the motion relationships between rotating and sliding components to determine displacement, velocity, and acceleration of the piston or slider. Unlike four-bar linkages, which consist of four rigid links connected by revolute joints creating complex coupler curves, slider-crank mechanisms convert rotary motion into linear motion through a crank, connecting rod, and piston arrangement. Key parameters such as crank angle, angular velocity, and length ratios are critical for accurately modeling the piston trajectory and dynamic behavior in applications like internal combustion engines and compressors.

Applications in Engineering and Industry

The four-bar mechanism is widely used in robotic arms, machine linkages, and suspension systems for its ability to provide complex motion paths and force transmission in industrial automation. Slider-crank mechanisms dominate internal combustion engines, compressors, and pumps due to their efficient conversion of rotary motion into linear motion or vice versa. Engineering applications leverage the four-bar for precision linkage design, while slider-cranks excel in power transmission where linear reciprocating motion is required.

Advantages of Four-Bar Mechanisms

Four-bar mechanisms offer greater structural simplicity and robustness compared to slider-crank systems, facilitating easier maintenance and longer operational life. Their ability to achieve complex motion paths with fewer moving parts enhances precision in mechanical linkages used in robotics and automotive applications. This results in improved efficiency and reduced wear, making four-bar linkages ideal for compact and reliable kinematic designs.

Advantages of Slider-Crank Mechanisms

Slider-crank mechanisms provide efficient conversion of rotary motion to linear motion, making them ideal for engines and pumps. Their simple design allows for smooth operation with fewer components, reducing wear and maintenance requirements. Enhanced force transmission and the ability to handle high loads distinguish slider-crank mechanisms from four-bar linkages in many mechanical applications.

Limitations and Challenges

Four-bar linkages face challenges in achieving complex motion paths and often require precise dimensional synthesis to avoid singular positions and ensure smooth operation. Slider-crank mechanisms are limited by higher friction and wear due to sliding contact, leading to reduced efficiency and increased maintenance. Both mechanisms demand careful design to manage load distribution and dynamic forces, with slider-crank systems particularly constrained by reciprocating mass affecting vibration and stability.

Selection Criteria: Choosing the Right Mechanism

Selecting between a four-bar linkage and a slider-crank mechanism hinges on desired motion type, load capacity, and spatial constraints. Four-bar linkages excel in complex planar motion with versatile output paths, while slider-cranks provide efficient linear motion and higher force transmission in compact designs. Application-specific factors such as precision, speed, and maintenance needs also dictate the optimal mechanism choice.

Four-bar Infographic

libterm.com

libterm.com