A Parker truss is a specific type of truss bridge design characterized by its polygonal top chord that efficiently distributes loads, making it ideal for longer spans. This engineering structure combines strength and material efficiency, often used in railway and highway bridges where durability is crucial. Discover how a Parker truss can enhance your infrastructure projects by exploring the details in this article.

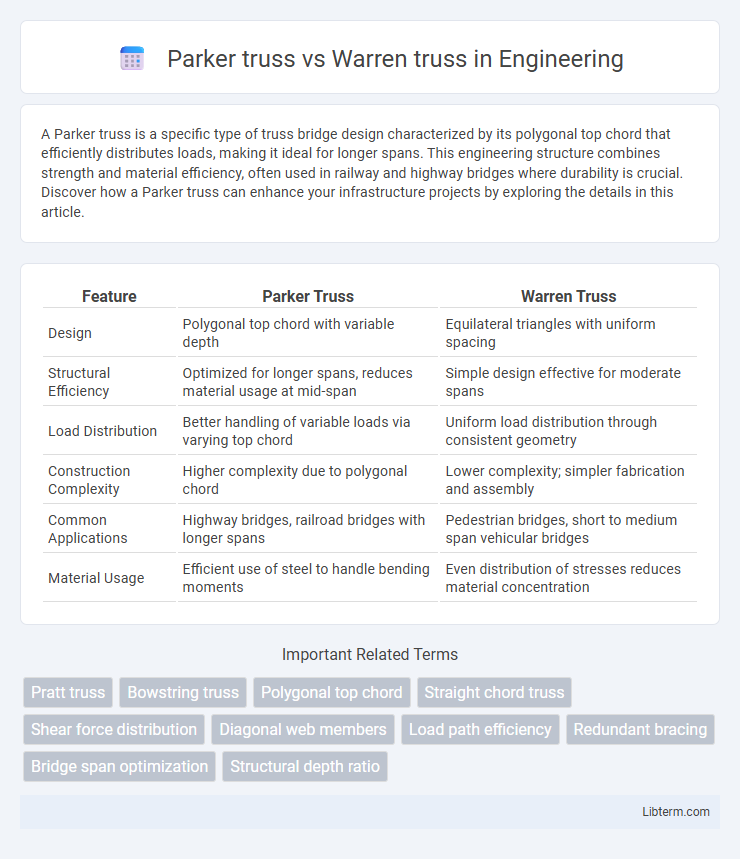

Table of Comparison

| Feature | Parker Truss | Warren Truss |

|---|---|---|

| Design | Polygonal top chord with variable depth | Equilateral triangles with uniform spacing |

| Structural Efficiency | Optimized for longer spans, reduces material usage at mid-span | Simple design effective for moderate spans |

| Load Distribution | Better handling of variable loads via varying top chord | Uniform load distribution through consistent geometry |

| Construction Complexity | Higher complexity due to polygonal chord | Lower complexity; simpler fabrication and assembly |

| Common Applications | Highway bridges, railroad bridges with longer spans | Pedestrian bridges, short to medium span vehicular bridges |

| Material Usage | Efficient use of steel to handle bending moments | Even distribution of stresses reduces material concentration |

Introduction to Parker and Warren Truss Bridges

Parker truss bridges feature a polygonal top chord that reduces material usage and stress by varying the length of members, making them efficient for long spans. Warren truss bridges employ equilateral triangles in a repetitive pattern, distributing loads evenly with minimal use of diagonal members, ideal for medium spans. Both designs optimize structural integrity but differ in complexity and application depending on span length and load requirements.

Historical Development of Parker and Warren Trusses

The Warren truss, patented by James Warren and Willoughby Monzani in 1848, introduced an efficient design using equilateral triangles to evenly distribute loads, marking a significant advancement in 19th-century bridge engineering. The Parker truss evolved from the Pratt truss in the late 19th and early 20th centuries, featuring a polygonal top chord that allowed longer spans and material savings, becoming popular for railroad and highway bridges in the United States. Both truss types reflect the era's emphasis on optimizing structural efficiency and material use, influencing bridge construction through their distinctive geometric and load-distribution approaches.

Structural Design Overview

The Parker truss features a polygonal top chord with varying panel lengths, optimizing material use by distributing loads more efficiently and reducing bending moments in bridge spans. In contrast, the Warren truss employs equilateral triangles with uniform members, providing simplicity and balanced load distribution through direct axial forces in its members. Both designs address different span lengths and load requirements, with the Parker truss favored for longer spans requiring reduced weight and the Warren truss preferred for simpler, shorter span applications.

Key Differences in Geometry

The Parker truss features a polygonal top chord that slopes downward with multiple segments, creating a curved or bent appearance optimized for longer spans and varying load distributions. In contrast, the Warren truss consists of equilateral triangles formed by straight, evenly spaced members that distribute loads through alternating tension and compression. The key geometric difference lies in the Parker's variable-depth top chord versus the Warren's uniform triangular framework, impacting structural efficiency and aesthetic design.

Load Distribution and Efficiency

The Parker truss, characterized by its polygonal top chord, excels in distributing loads more efficiently across varying spans by reducing bending moments in longer sections. The Warren truss utilizes equilateral triangles, ensuring a uniform load distribution and minimizing material use due to its inherent geometric stability. Both designs offer high efficiency, but the Parker truss is preferred for longer spans where load variation demands optimized stress distribution.

Material Usage and Cost Considerations

The Parker truss typically uses more material due to its polygonal top chord design, which increases web member lengths and connections, leading to higher construction costs compared to the simpler Warren truss. The Warren truss, characterized by its equilateral triangle pattern, optimizes material usage with fewer members and uniform stress distribution, resulting in lower fabrication and maintenance expenses. Cost considerations favor the Warren truss for economical projects, while the Parker truss may be justified in applications requiring longer spans or specific load distributions.

Construction Techniques and Challenges

Parker truss construction involves variable-depth members that require precise fabrication and fitting to ensure structural integrity, presenting challenges in complex joint connections and load distribution. Warren truss features a series of equilateral triangles with uniform member lengths, simplifying fabrication but demanding careful alignment to maintain stability under dynamic loads. Both designs require skilled labor and accurate assembly techniques to address their respective geometric complexities and optimize load-bearing performance.

Common Applications of Parker and Warren Trusses

Parker trusses are commonly used in long-span bridges and railroad bridges due to their curved top chord, which efficiently distributes loads and reduces material usage in heavy-load scenarios. Warren trusses find frequent application in highway bridges, pedestrian bridges, and roof supports, prized for their simplicity, even distribution of forces, and ease of fabrication. Both truss types serve critical roles in structural engineering, with Parker trusses favored for longer spans requiring more material optimization and Warren trusses preferred for shorter spans and modular construction.

Strengths and Weaknesses Comparison

Parker truss offers enhanced strength through its polygonal top chord, efficiently distributing loads and reducing material use in long-span bridges, yet its complex design increases fabrication costs and maintenance needs. Warren truss features a simpler design with equilateral triangles, providing uniform stress distribution and ease of construction but may require heavier members to resist bending in certain loading conditions. Both truss types balance material efficiency and structural performance, with Parker truss excelling in longer spans and Warren truss favored for cost-effectiveness in moderate spans.

Choosing the Right Truss: Factors to Consider

When choosing between Parker truss and Warren truss designs, factors such as load distribution, span length, and material efficiency are critical. Parker trusses, characterized by their polygonal top chord, are advantageous for longer spans and heavier loads due to enhanced stress distribution. Warren trusses, featuring equilateral triangles, offer simplicity and cost-effectiveness, making them suitable for shorter spans with moderate loading conditions.

Parker truss Infographic

libterm.com

libterm.com