Aerodynamic drag significantly impacts vehicle performance by opposing motion through air resistance, reducing fuel efficiency and speed. Understanding the factors influencing drag, such as shape, surface texture, and velocity, can help optimize design and improve energy consumption. Explore the rest of this article to learn how reducing aerodynamic drag can enhance your vehicle's efficiency and performance.

Table of Comparison

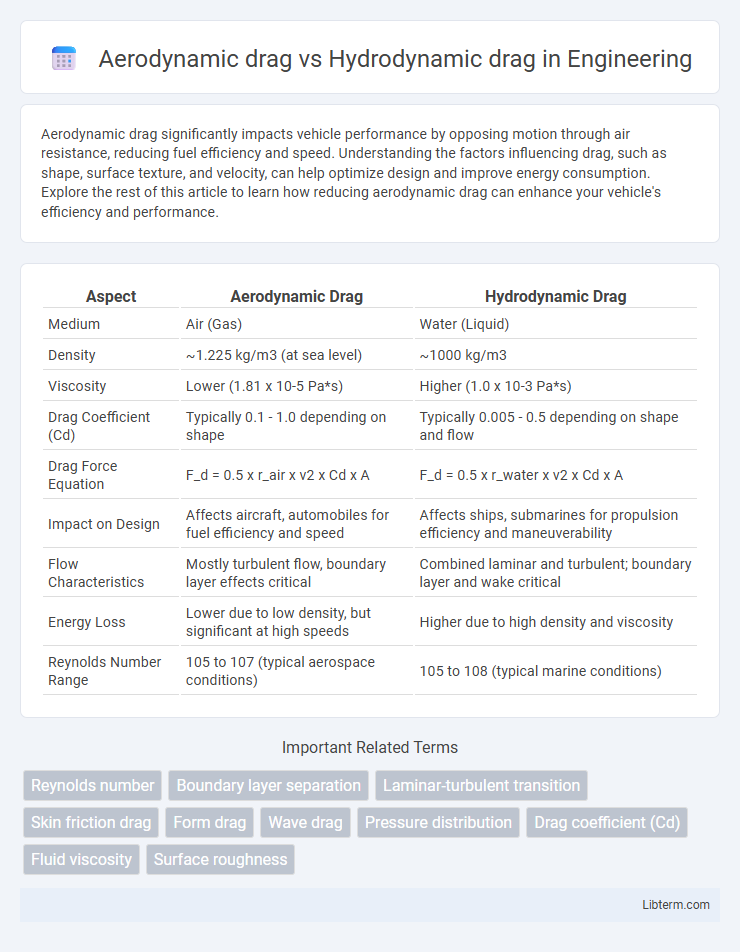

| Aspect | Aerodynamic Drag | Hydrodynamic Drag |

|---|---|---|

| Medium | Air (Gas) | Water (Liquid) |

| Density | ~1.225 kg/m3 (at sea level) | ~1000 kg/m3 |

| Viscosity | Lower (1.81 x 10-5 Pa*s) | Higher (1.0 x 10-3 Pa*s) |

| Drag Coefficient (Cd) | Typically 0.1 - 1.0 depending on shape | Typically 0.005 - 0.5 depending on shape and flow |

| Drag Force Equation | F_d = 0.5 x r_air x v2 x Cd x A | F_d = 0.5 x r_water x v2 x Cd x A |

| Impact on Design | Affects aircraft, automobiles for fuel efficiency and speed | Affects ships, submarines for propulsion efficiency and maneuverability |

| Flow Characteristics | Mostly turbulent flow, boundary layer effects critical | Combined laminar and turbulent; boundary layer and wake critical |

| Energy Loss | Lower due to low density, but significant at high speeds | Higher due to high density and viscosity |

| Reynolds Number Range | 105 to 107 (typical aerospace conditions) | 105 to 108 (typical marine conditions) |

Introduction to Drag Forces

Aerodynamic drag refers to the resistance a solid body encounters when moving through air, influenced by factors such as air density, velocity, shape, and surface roughness. Hydrodynamic drag, on the other hand, occurs when an object moves through a liquid, primarily water, and depends on fluid viscosity, flow regime, and object geometry. Both drag forces are critical in engineering designs aimed at optimizing performance in vehicles, aircraft, and marine vessels by minimizing energy loss caused by resistance in their respective fluid environments.

Defining Aerodynamic Drag

Aerodynamic drag refers to the resistance force experienced by an object moving through air, caused by the interaction between the object's surface and the air molecules. This drag depends on factors such as shape, surface roughness, air density, and velocity, and it significantly affects the performance and efficiency of vehicles, aircraft, and sports equipment. In contrast, hydrodynamic drag occurs when objects move through water or other fluids, involving similar principles but differing fluid properties like density and viscosity.

Defining Hydrodynamic Drag

Hydrodynamic drag refers to the resistance experienced by an object moving through a fluid, such as water, caused by the fluid's viscosity and pressure differences around the object. Unlike aerodynamic drag, which occurs in gases like air, hydrodynamic drag is influenced by factors such as fluid density, object shape, surface roughness, and flow velocity within liquids. Understanding hydrodynamic drag is essential in designing efficient marine vessels, submarines, and underwater vehicles to minimize energy loss and improve performance.

Key Principles of Drag in Fluids

Aerodynamic drag arises from the interaction between air molecules and a moving object, primarily influenced by factors like air density, velocity, and surface roughness, while hydrodynamic drag involves fluid resistance encountered by objects moving through water, where fluid viscosity and flow patterns play crucial roles. Both types of drag are governed by principles such as pressure drag, skin friction drag, and flow separation, which dictate the overall resistance experienced in their respective media. Understanding these key principles enables optimized design in applications ranging from aircraft wings to submarine hulls, enhancing efficiency by minimizing energy loss due to drag.

Factors Affecting Aerodynamic Drag

Aerodynamic drag is primarily influenced by factors such as air density, velocity, surface roughness, and object shape, which determine the resistance an object encounters moving through air. In contrast, hydrodynamic drag deals with fluid properties like viscosity and water density, affecting forces on objects in water. Understanding parameters like Reynolds number, drag coefficient, and frontal area is critical for optimizing aerodynamic drag in engineering applications like automotive and aerospace design.

Factors Influencing Hydrodynamic Drag

Hydrodynamic drag is influenced by fluid viscosity, surface roughness, and object shape, which affect the boundary layer development and flow separation around submerged bodies. Unlike aerodynamic drag, hydrodynamic drag also depends heavily on water density and flow velocity, resulting in higher resistance due to water's greater density compared to air. Factors such as turbulent versus laminar flow and the presence of cavitation further modify hydrodynamic drag, impacting vessel efficiency and energy consumption.

Comparative Analysis: Air vs Water Resistance

Aerodynamic drag, which occurs when an object moves through air, is influenced primarily by air density, velocity, and surface shape, resulting in lower resistance compared to hydrodynamic drag that acts on objects moving through water, a much denser medium. Water's density is approximately 800 times greater than air, causing hydrodynamic drag to generate significantly stronger forces that require more energy for propulsion or movement at similar speeds. The Reynolds number and flow characteristics also differ between these two types of drag, impacting the design considerations for vehicles and vessels optimized for air or water travel.

Applications in Engineering and Design

Aerodynamic drag significantly influences the design and efficiency of vehicles such as cars and aircraft by reducing fuel consumption and enhancing performance through streamlined shapes and materials that minimize air resistance. Hydrodynamic drag plays a critical role in naval engineering and underwater vehicle design, where optimizing hull shapes and surface coatings decreases water resistance, improves speed, and boosts fuel efficiency. Both drag types require precise computational fluid dynamics (CFD) simulations and wind or water tunnel testing to tailor engineering solutions for specific environmental conditions and operational requirements.

Methods for Reducing Drag

Aerodynamic drag reduction techniques include streamlining vehicle shapes, using smooth surfaces, and adding aerodynamic components like spoilers and diffusers to control airflow and minimize turbulence. Hydrodynamic drag is often reduced through hull design optimization, applying specialized coatings such as antifouling paints, and employing air lubrication systems to create a layer of bubbles between the vessel hull and water. Both fields utilize computational fluid dynamics (CFD) to simulate and refine designs for optimal drag reduction performance.

Future Trends in Drag Reduction

Future trends in aerodynamic drag reduction emphasize advanced materials like graphene-infused composites and active flow control technologies such as morphing surfaces and plasma actuators to optimize airflow around vehicles and aircraft. Innovations in hydrodynamic drag focus on biomimetic designs inspired by marine animals, ultra-smooth hull coatings, and air lubrication systems to minimize frictional resistance in ships and underwater vehicles. Both fields increasingly leverage artificial intelligence and machine learning algorithms to simulate and predict drag patterns, enabling more efficient, adaptive drag reduction solutions in real-time operational environments.

Aerodynamic drag Infographic

libterm.com

libterm.com