Double shear refers to a type of mechanical loading where a force is applied in such a way that it causes two shear planes to form simultaneously in a material or fastener, effectively doubling the shear strength compared to single shear. This concept is crucial in structural engineering and mechanical design to ensure the integrity and safety of connections under load. Explore the rest of the article to understand how double shear enhances material performance and where it is commonly applied in your engineering projects.

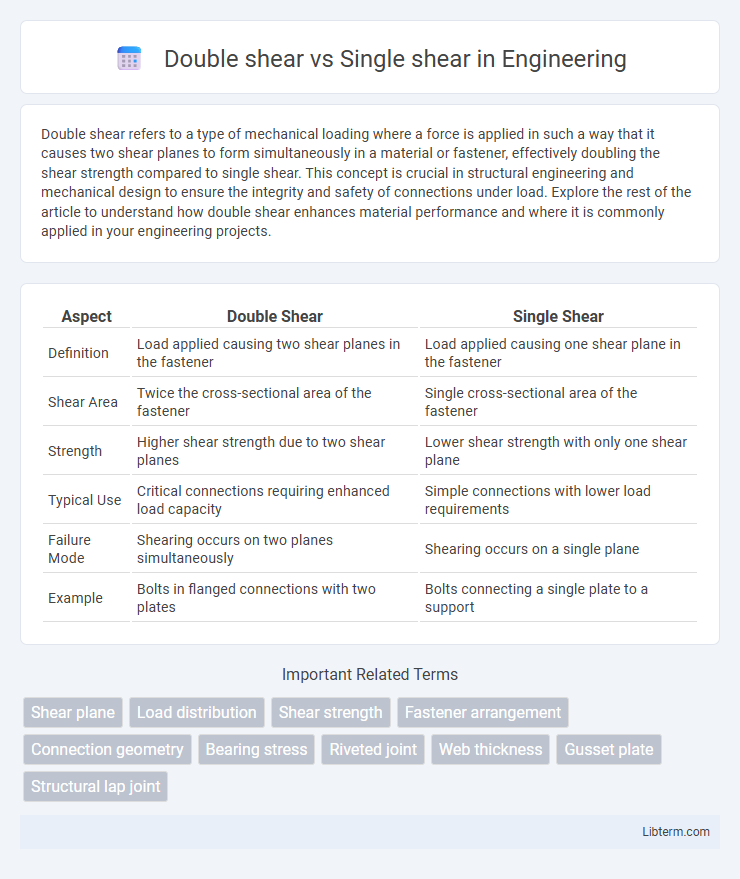

Table of Comparison

| Aspect | Double Shear | Single Shear |

|---|---|---|

| Definition | Load applied causing two shear planes in the fastener | Load applied causing one shear plane in the fastener |

| Shear Area | Twice the cross-sectional area of the fastener | Single cross-sectional area of the fastener |

| Strength | Higher shear strength due to two shear planes | Lower shear strength with only one shear plane |

| Typical Use | Critical connections requiring enhanced load capacity | Simple connections with lower load requirements |

| Failure Mode | Shearing occurs on two planes simultaneously | Shearing occurs on a single plane |

| Example | Bolts in flanged connections with two plates | Bolts connecting a single plate to a support |

Introduction to Shear Forces

Shear forces occur when two opposing forces act parallel but in opposite directions on a material, potentially causing deformation or failure along the plane of action. Single shear involves one shear plane where the force acts, while double shear consists of two shear planes, effectively distributing the load and increasing the structural capacity. Understanding the distinction between single and double shear is crucial in mechanical design to ensure optimal strength, safety, and material efficiency in connections like bolts, rivets, or welds.

Defining Single Shear

Single shear occurs when a fastener, such as a bolt or rivet, passes through two connected components and is subjected to a force that causes one shear plane, resulting in a single cut or shear area. In contrast, double shear involves two shear planes, where the fastener passes through three components, effectively doubling the shear area and increasing load capacity. Understanding single shear is essential for calculating shear stress and ensuring the structural integrity of joints in mechanical and civil engineering applications.

Understanding Double Shear

Double shear occurs when a fastener or material is subjected to two distinct shear planes simultaneously, effectively doubling its load-carrying capacity compared to single shear, where only one shear plane is present. In engineering applications, understanding double shear is crucial for designing joints that require higher strength and stability, as the load is distributed across two planes, reducing the stress on each plane. Common scenarios of double shear include riveted, bolted, or pinned connections where the fastener passes through three plates or components, creating two shear planes that enhance structural integrity.

Key Differences: Single vs Double Shear

Single shear involves a load applied to a material or fastener causing it to fail along one plane, typically resulting in lower strength compared to double shear, where the load is applied across two planes. In double shear, the force is distributed over two cross-sectional areas, effectively doubling the shear resistance and enhancing structural integrity. Single shear scenarios are common in simple beams and fastener connections, while double shear is preferred in mechanical joints requiring higher load capacity and safety.

Mechanical Strength Comparison

Double shear joints provide higher mechanical strength compared to single shear joints due to the load being distributed across two shear planes instead of one. This configuration effectively doubles the shear area, resulting in increased resistance to shear forces and improved structural integrity. Consequently, double shear connections are preferred in applications demanding enhanced durability and load-bearing capacity.

Applications of Single Shear

Single shear connections are widely used in engineering applications such as bolted joints, riveted connections, and mechanical fasteners where the load is transmitted through a single shear plane. These connections are common in structural steel frameworks, machinery assemblies, and aerospace components due to their simplicity and ease of inspection. Single shear is preferred for less complex load scenarios, offering efficient load transfer with reduced manufacturing costs compared to double shear configurations.

Uses of Double Shear in Engineering

Double shear joints provide enhanced load-bearing capacity compared to single shear connections, making them ideal for critical structural applications in engineering such as bridge construction and heavy machinery assembly. The double shear design distributes applied forces over two shear planes, reducing stress concentration and increasing joint stability under dynamic loads. This configuration is commonly used in mechanical linkages and structural steel frameworks where safety, durability, and resistance to shear failure are paramount.

Advantages and Disadvantages

Double shear joints offer greater strength and load-bearing capacity by distributing forces over two shear planes, reducing stress concentration and enhancing structural integrity. Single shear joints are simpler to manufacture and inspect, making them cost-effective for lighter loads but may suffer from higher stress on the single shear plane, increasing the risk of failure. Double shear designs often require more material and fabrication complexity, whereas single shear connections provide ease of assembly and reduced weight in applications with lower shear demands.

Factors Influencing Shear Selection

Material thickness, load direction, and connection requirements predominantly influence the choice between double shear and single shear. Double shear provides greater strength and stability by distributing the load across two shear planes, making it optimal for high-stress applications and thicker materials. Single shear is typically chosen for simpler, lighter-duty joints with less material thickness and where ease of assembly and cost efficiency are priorities.

Conclusion: Choosing the Right Shear Type

Selecting the appropriate shear type depends on load capacity and structural requirements, with double shear offering greater strength and stability due to load distribution over two planes. Single shear is suitable for lighter loads and simpler connections, providing ease of installation and cost efficiency. Engineers must evaluate the application's stress demands and safety factors to ensure optimal performance and longevity.

Double shear Infographic

libterm.com

libterm.com