Multi-point cutting enhances manufacturing efficiency by using multiple cutting edges simultaneously, reducing cycle times and improving surface finish quality. This technique minimizes tool wear and heat generation, extending tool life and ensuring cost-effective production. Discover how multi-point cutting can transform your machining processes in the rest of this article.

Table of Comparison

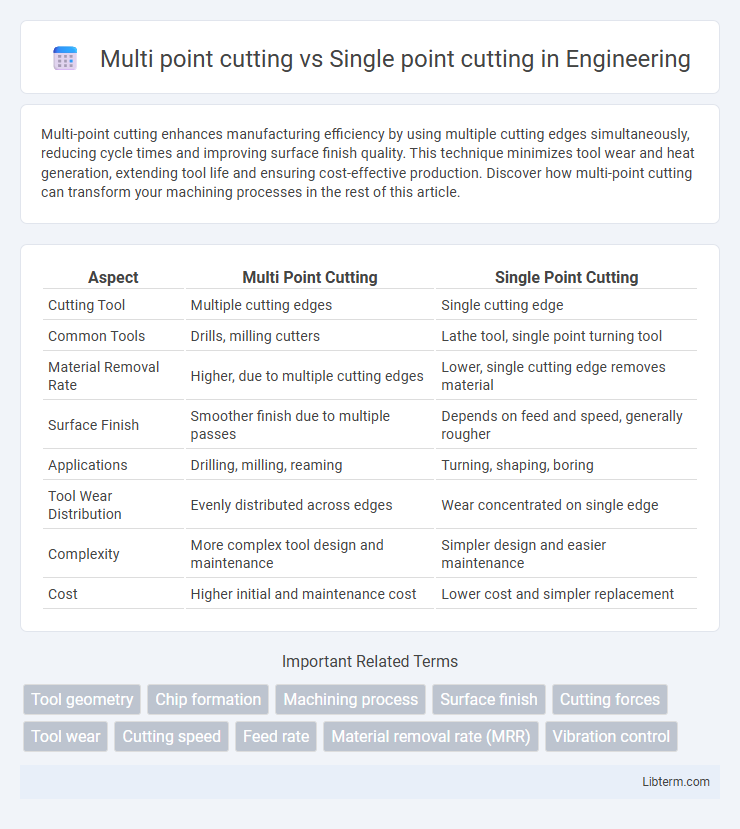

| Aspect | Multi Point Cutting | Single Point Cutting |

|---|---|---|

| Cutting Tool | Multiple cutting edges | Single cutting edge |

| Common Tools | Drills, milling cutters | Lathe tool, single point turning tool |

| Material Removal Rate | Higher, due to multiple cutting edges | Lower, single cutting edge removes material |

| Surface Finish | Smoother finish due to multiple passes | Depends on feed and speed, generally rougher |

| Applications | Drilling, milling, reaming | Turning, shaping, boring |

| Tool Wear Distribution | Evenly distributed across edges | Wear concentrated on single edge |

| Complexity | More complex tool design and maintenance | Simpler design and easier maintenance |

| Cost | Higher initial and maintenance cost | Lower cost and simpler replacement |

Introduction to Cutting Processes

Multi-point cutting involves several cutting edges simultaneously removing material, commonly seen in milling and drilling operations, enhancing efficiency and surface finish. Single-point cutting uses a single cutting edge, typical in turning and shaping, allowing precise control over material removal and surface geometry. Both processes are fundamental in manufacturing, optimized by tool geometry, cutting speed, and feed rate to achieve desired material removal and part accuracy.

Defining Single Point Cutting

Single point cutting involves a single cutting edge removing material from a workpiece, commonly used in turning, shaping, and grinding operations. This method offers precise control over the cutting process, making it ideal for creating intricate details and smooth finishes. In contrast, multi point cutting employs multiple cutting edges simultaneously, often seen in milling and drilling, enhancing material removal rates but with less precision per individual cutting edge.

Understanding Multi Point Cutting

Multi point cutting involves multiple cutting edges engaging the workpiece simultaneously, enhancing material removal rates and improving machining efficiency compared to single point cutting, which uses only one cutting edge. This technique reduces tool wear by distributing cutting forces across several points, leading to increased tool life and better surface finish. CNC milling and drilling commonly utilize multi point cutting to achieve precision and reduce machining time in manufacturing processes.

Key Differences Between Single and Multi Point Cutting

Single point cutting tools feature only one cutting edge, typically used in turning and shaping operations, providing precise control and fine surface finish but slower material removal rates. Multi point cutting tools, such as milling cutters and drills, have multiple cutting edges that simultaneously engage the workpiece, enabling higher material removal rates and improved productivity in complex machining tasks. Key differences include tool geometry, cutting speed, surface finish quality, and application suitability, with single point tools favoring precision and multi point tools excelling in speed and efficiency for larger volumes.

Advantages of Single Point Cutting

Single point cutting tools offer enhanced precision and control, making them ideal for intricate machining tasks and high-accuracy applications such as turning and milling. They provide superior surface finish quality due to consistent cutting geometry and reduced tool chatter, resulting in tighter dimensional tolerances. Single point cutting also simplifies tool setup and maintenance, reducing downtime and improving overall manufacturing efficiency.

Advantages of Multi Point Cutting

Multi point cutting tools, such as milling cutters, enable higher material removal rates and improved surface finish compared to single point cutting tools like lathes, due to the simultaneous engagement of multiple cutting edges. These tools distribute cutting forces across several points, reducing tool wear and increasing tool life, which enhances overall productivity and cost efficiency in manufacturing processes. Multi point cutting operations also allow for complex geometries and faster machining cycles, making them ideal for high-volume production environments.

Limitations of Single Point Cutting

Single point cutting tools face limitations such as slower material removal rates and higher tool wear due to concentrated cutting forces on a single edge. These tools struggle with poor surface finish and increased heat generation during machining hard materials, limiting efficiency. In contrast, multi point cutting distributes the load across several edges, enhancing durability and productivity.

Limitations of Multi Point Cutting

Multi-point cutting tools, such as milling cutters and drills, face limitations including increased tool wear due to multiple cutting edges engaging the workpiece simultaneously, leading to complex stress distribution and heat generation. Precision can be compromised as vibrations and deflections accumulate across multiple points, reducing the accuracy compared to single-point cutting tools like lathes. Additionally, multi-point cutting systems require higher maintenance and tooling costs, making them less suitable for fine finishing or intricate detail work.

Typical Applications for Each Cutting Method

Multi point cutting is typically used in machining processes like milling, drilling, and broaching, where multiple cutting edges engage the workpiece simultaneously to remove material efficiently and achieve higher productivity. Single point cutting finds applications primarily in turning, shaping, and grinding, providing precise dimensional control and better surface finishes for parts such as shafts, cylinders, and internal diameters. Industries like automotive and aerospace extensively use multi point cutting for rapid material removal, while single point cutting is favored in toolmaking and precision engineering for detailed and accurate shaping.

Choosing the Right Cutting Process for Your Needs

Multi-point cutting tools like milling cutters offer higher material removal rates and longer tool life, making them ideal for complex shapes and large-scale production. Single-point cutting tools such as lathe tools provide superior precision and surface finish, suited for turning operations and custom machining tasks. Selecting the right cutting process depends on factors like workpiece material, desired tolerances, machining speed, and production volume to optimize efficiency and quality.

Multi point cutting Infographic

libterm.com

libterm.com