Roots blowers deliver reliable, high-volume air flow for various industrial applications, enhancing efficiency in pneumatic conveying and aeration processes. Their robust design ensures consistent pressure and low maintenance requirements, making them ideal for continuous operation. Discover more about how a Roots blower can improve your system's performance by exploring the rest of this article.

Table of Comparison

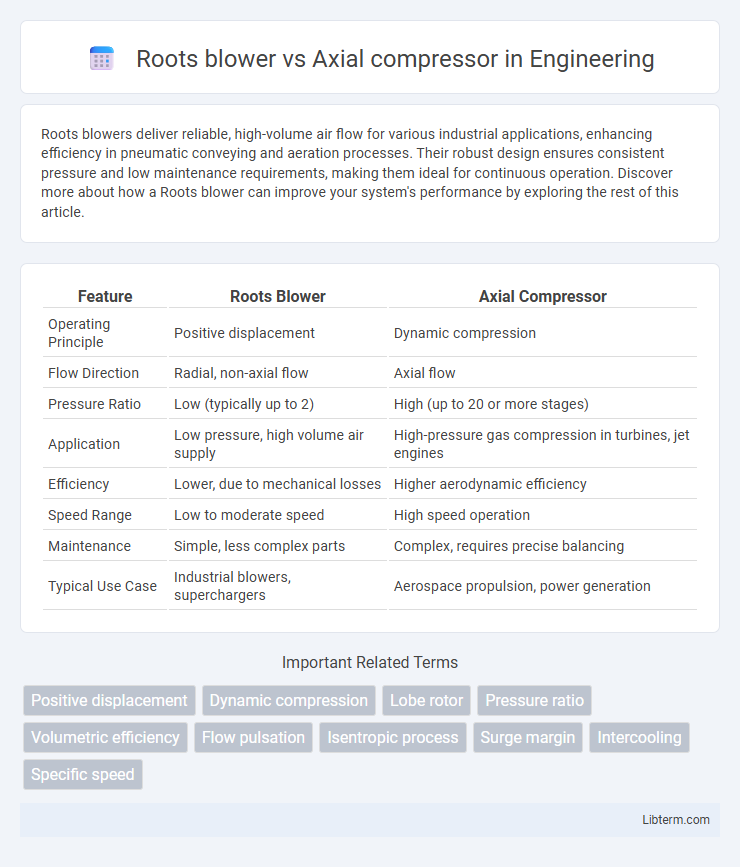

| Feature | Roots Blower | Axial Compressor |

|---|---|---|

| Operating Principle | Positive displacement | Dynamic compression |

| Flow Direction | Radial, non-axial flow | Axial flow |

| Pressure Ratio | Low (typically up to 2) | High (up to 20 or more stages) |

| Application | Low pressure, high volume air supply | High-pressure gas compression in turbines, jet engines |

| Efficiency | Lower, due to mechanical losses | Higher aerodynamic efficiency |

| Speed Range | Low to moderate speed | High speed operation |

| Maintenance | Simple, less complex parts | Complex, requires precise balancing |

| Typical Use Case | Industrial blowers, superchargers | Aerospace propulsion, power generation |

Introduction: Understanding Roots Blower and Axial Compressor

Roots blowers and axial compressors serve distinct roles in fluid dynamics, with the former operating as positive displacement devices that deliver a fixed volume of air per revolution and the latter designed for continuous airflow compression through multiple rotating blades. Roots blowers excel in low-pressure, high-volume applications such as pneumatic conveying and supercharging engines, while axial compressors are favored in high-pressure, high-efficiency environments like jet engines and gas turbines. Their foundational principles revolve around airflow handling: Roots blowers use lobed rotors to trap and move air, whereas axial compressors progressively increase air pressure via aerodynamic blade action along the compressor shaft.

Working Principle: Roots Blower vs Axial Compressor

Roots blowers operate on a positive displacement principle using two meshing lobed rotors to trap and transfer air through the casing, producing constant volumetric flow regardless of pressure conditions. Axial compressors function based on dynamic compression, where air flows continuously parallel to the shaft through multiple stages of rotating and stationary blades, gradually increasing pressure by converting kinetic energy into pressure energy. The Roots blower generates air via mechanical trapping and displacement, while the axial compressor relies on aerodynamic acceleration and pressure rise across blade stages for efficient high-speed compression.

Core Design Differences

Roots blowers utilize positive displacement with meshing lobes to move fixed volumes of air, ensuring constant flow regardless of pressure changes, whereas axial compressors rely on rotating blades to progressively increase air velocity and pressure in a continuous flow. The core design of a Roots blower features large, interlocking lobes housed in a casing, operating at low speeds with minimal compression within the unit. In contrast, axial compressors employ multiple stages of rotor and stator blades aligned along the flow axis, enabling high-efficiency compression suitable for applications like jet engines and gas turbines.

Performance Comparison: Pressure and Flow Characteristics

Roots blowers deliver constant volumetric flow regardless of pressure, excelling in low to moderate pressure applications with stable flow rates up to 2 bar gauge. Axial compressors achieve higher pressure ratios, often exceeding 10:1, by progressively increasing air velocity through multiple stages, making them suitable for high flow and high-pressure systems. While Roots blowers maintain steady flow with pulsation and moderate noise, axial compressors optimize pressure rise and efficiency in aerodynamic environments but require precise design to minimize surge and stall.

Applications: Industrial Uses of Roots Blower and Axial Compressor

Roots blowers are commonly used in industrial applications requiring low to moderate pressure and high volume airflow, such as pneumatic conveying, wastewater treatment aeration, and combustion air supply in boilers. Axial compressors are predominantly utilized in high-speed, high-pressure applications like gas turbines, jet engines, and large-scale HVAC systems due to their efficiency at compressing large volumes of air with minimal pressure rise per stage. The choice between these devices depends on specific industrial requirements, including pressure range, flow rate, and energy efficiency.

Energy Efficiency and Power Consumption

Roots blowers exhibit lower energy efficiency compared to axial compressors due to higher pressure losses and constant volume displacement operation, leading to increased power consumption for equivalent airflow. Axial compressors achieve superior energy efficiency by compressing air through aerodynamic stages that reduce pressure drop and optimize flow dynamics, resulting in lower power requirements. For industrial applications prioritizing minimal energy use, axial compressors are generally preferred over Roots blowers despite higher initial costs.

Maintenance Requirements and Durability

Roots blowers require regular lubrication and periodic inspection of rotors and seals to maintain optimal performance, with simpler mechanical design contributing to easier maintenance. Axial compressors demand precise alignment and more frequent checks on blades and bearings due to higher operating speeds, often necessitating specialized tools and expertise. In terms of durability, Roots blowers excel in handling dirty or contaminated air, resulting in longer service intervals, while axial compressors are more susceptible to damage from particulates but offer superior efficiency in clean, high-speed applications.

Advantages and Limitations of Each Technology

Roots blowers provide high volumetric efficiency and stable pressure output at low to moderate speeds, making them ideal for applications requiring consistent airflow and moderate pressure rise. Axial compressors offer superior aerodynamic performance and energy efficiency at high flow rates and pressures but are generally more complex and sensitive to flow variations. While Roots blowers have simpler construction and better durability in dirty environments, axial compressors demand precise operating conditions and advanced maintenance to maintain optimal performance.

Cost Analysis: Initial Investment and Operating Expenses

Roots blowers typically require lower initial investment compared to axial compressors due to simpler design and manufacturing processes. Operating expenses for Roots blowers can be higher because of lower efficiency, leading to increased energy consumption during continuous operation. Axial compressors, while having higher upfront costs, generally offer better energy efficiency and reduced long-term operating expenses in high-volume industrial applications.

Choosing the Right Solution: Roots Blower or Axial Compressor

Selecting between a Roots blower and an axial compressor depends on the required pressure ratio and flow characteristics; Roots blowers excel in low to medium pressure applications with steady, pulsation-free airflow, while axial compressors are ideal for high-pressure, high-flow scenarios demanding efficient continuous compression. Roots blowers deliver positive displacement performance and are commonly used in pneumatic conveying and wastewater aeration due to their robustness and ability to handle dirty gases. Axial compressors, featuring multiple stages of rotating blades, provide superior aerodynamic efficiency in aerospace and power generation industries where precise pressure control and energy efficiency are critical.

Roots blower Infographic

libterm.com

libterm.com