V-belts are essential components in many mechanical systems, designed to transmit power efficiently between pulleys while minimizing slippage and wear. Their unique trapezoidal cross-section ensures a secure grip and optimal alignment, enhancing the performance and longevity of engines and machinery. Discover how choosing the right V-belt can improve Your equipment's reliability by reading the rest of the article.

Table of Comparison

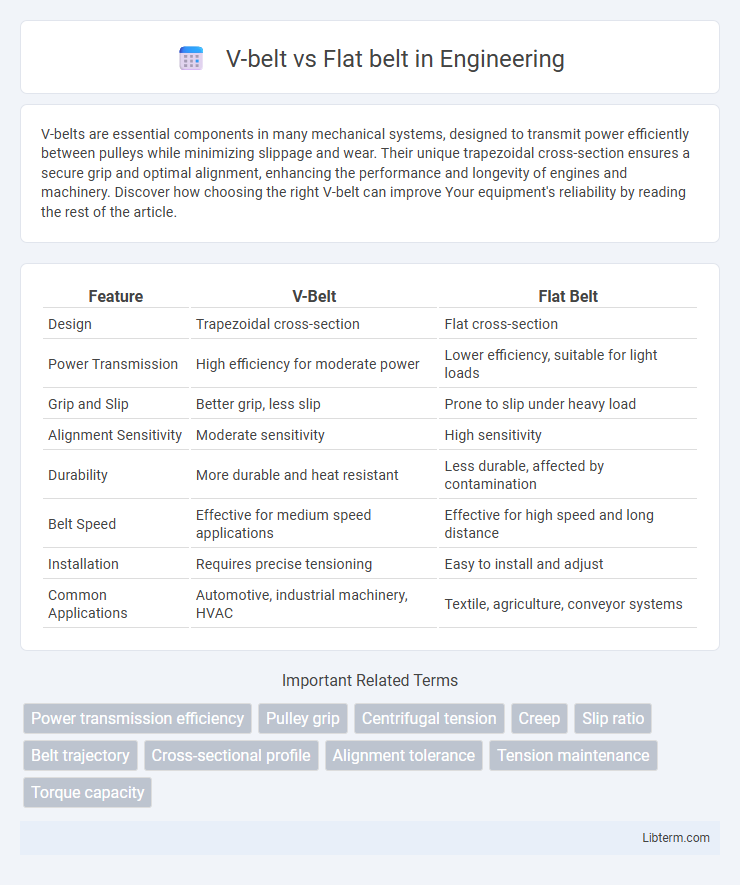

| Feature | V-Belt | Flat Belt |

|---|---|---|

| Design | Trapezoidal cross-section | Flat cross-section |

| Power Transmission | High efficiency for moderate power | Lower efficiency, suitable for light loads |

| Grip and Slip | Better grip, less slip | Prone to slip under heavy load |

| Alignment Sensitivity | Moderate sensitivity | High sensitivity |

| Durability | More durable and heat resistant | Less durable, affected by contamination |

| Belt Speed | Effective for medium speed applications | Effective for high speed and long distance |

| Installation | Requires precise tensioning | Easy to install and adjust |

| Common Applications | Automotive, industrial machinery, HVAC | Textile, agriculture, conveyor systems |

Introduction to Power Transmission Belts

Power transmission belts are essential components in mechanical systems, transferring motion and power between pulleys. V-belts feature a trapezoidal cross-section providing high friction and efficient power transfer in compact spaces, making them ideal for high-torque applications. Flat belts, characterized by their smooth, flat surface, offer flexibility and quiet operation, suitable for high-speed, low-torque environments with longer center distances.

What is a V-Belt?

A V-belt is a type of power transmission belt characterized by its trapezoidal cross-section, designed to fit into the V-shaped grooves of pulleys. This design provides better grip and increased friction, making V-belts ideal for transmitting higher torque in mechanical systems. Compared to flat belts, V-belts offer improved efficiency, durability, and reduced slippage in industrial and automotive applications.

What is a Flat Belt?

A flat belt is a flexible, continuous loop of material, typically leather or synthetic fabric, used to transmit power between rotating shafts in various mechanical systems. Unlike V-belts, flat belts rely on friction and a larger contact area to transfer motion efficiently, making them suitable for high-speed, low-torque applications. Flat belts offer smooth operation and reduced wear on pulleys, contributing to longer service life in industrial machinery and conveyor systems.

Design Differences: V-Belt vs Flat Belt

V-belts feature a trapezoidal cross-section that fits into pulleys with corresponding V-shaped grooves, enabling higher friction and torque transmission compared to flat belts. Flat belts have a rectangular cross-section and run on smooth pulleys, offering lower friction but allowing higher speeds and quieter operation. The design of V-belts provides better alignment and reduced slippage, making them suitable for heavy-duty power transmission, while flat belts excel in applications requiring lightweight, flexible drive systems.

Efficiency Comparison

V-belts typically offer higher efficiency than flat belts due to their improved grip and reduced slippage, with transmission efficiencies often reaching 95-98%. Flat belts, while suitable for high-speed applications, tend to have lower efficiency ranging from 90-95% because of increased friction and risk of misalignment. The choice between V-belt and flat belt significantly influences mechanical power transmission efficiency, impacting overall system performance and energy consumption.

Durability and Maintenance

V-belts typically offer greater durability due to their robust construction and resistance to slippage, making them ideal for high-torque applications. Flat belts require frequent maintenance as they are more prone to stretching and misalignment, which can reduce efficiency and lifespan. Proper tension adjustment and regular inspection are essential for maintaining optimal performance in both belt types.

Applications and Usage Scenarios

V-belts are widely used in automotive engines, industrial machinery, and agricultural equipment due to their ability to transmit high power efficiently while maintaining flexibility around pulleys. Flat belts find applications in conveyor systems, textile machines, and woodworking equipment where smooth, low-friction power transmission over long distances is required. V-belts perform better in scenarios demanding high torque and compact drives, whereas flat belts excel in light to moderate load applications emphasizing speed and alignment.

Cost Considerations

V-belts generally offer a cost-effective solution due to their compact design and efficient power transmission, requiring less maintenance and reducing downtime expenses. Flat belts, while initially cheaper, may incur higher long-term costs because of increased slippage and frequent adjustments or replacements. Evaluating total lifecycle expenses, V-belts often deliver better value for industrial applications prioritizing durability and consistent performance.

Advantages and Disadvantages

V-belts provide higher friction and better grip, making them ideal for transmitting power efficiently in tight spaces while minimizing slippage. Flat belts offer smoother operation and are easier to align, but they often require higher tension and can slip under heavy loads. V-belts tend to have a longer service life and can handle larger loads, whereas flat belts are simpler and more cost-effective for light-duty applications.

Choosing the Right Belt for Your Needs

Selecting the right belt depends on factors such as load capacity, pulley design, and operational speed; V-belts offer superior grip and power transmission in high-torque applications, while flat belts excel in high-speed and low-slippage scenarios. V-belts are preferred for their compact design and ability to handle misalignment, whereas flat belts provide smoother, quieter operation and easier maintenance. Evaluating the specific requirements of your machinery, including environmental conditions and durability expectations, ensures optimal performance and longevity.

V-belt Infographic

libterm.com

libterm.com