Casting plays a crucial role in film and theater, determining the success of a production by matching the right actors to specific roles. Understanding the nuances of casting can enhance your appreciation of character development and storytelling. Explore the full article to learn how casting decisions shape your favorite performances.

Table of Comparison

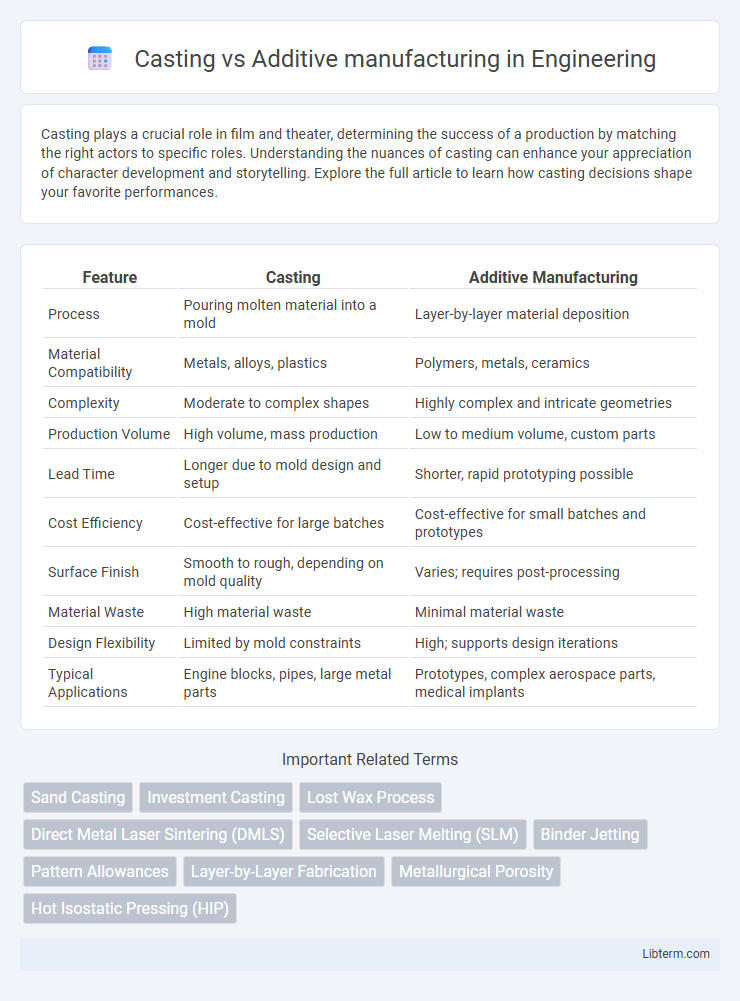

| Feature | Casting | Additive Manufacturing |

|---|---|---|

| Process | Pouring molten material into a mold | Layer-by-layer material deposition |

| Material Compatibility | Metals, alloys, plastics | Polymers, metals, ceramics |

| Complexity | Moderate to complex shapes | Highly complex and intricate geometries |

| Production Volume | High volume, mass production | Low to medium volume, custom parts |

| Lead Time | Longer due to mold design and setup | Shorter, rapid prototyping possible |

| Cost Efficiency | Cost-effective for large batches | Cost-effective for small batches and prototypes |

| Surface Finish | Smooth to rough, depending on mold quality | Varies; requires post-processing |

| Material Waste | High material waste | Minimal material waste |

| Design Flexibility | Limited by mold constraints | High; supports design iterations |

| Typical Applications | Engine blocks, pipes, large metal parts | Prototypes, complex aerospace parts, medical implants |

Introduction to Casting and Additive Manufacturing

Casting involves pouring molten material into a mold to achieve the desired shape, commonly used for metals and large-scale production due to its cost-effectiveness and ability to create complex geometries. Additive manufacturing, or 3D printing, builds objects layer by layer from digital models, offering high precision and customization for complex and low-volume parts. Both processes cater to different manufacturing needs, with casting excelling in mass production and additive manufacturing providing flexibility and rapid prototyping.

Definition and Overview of Casting

Casting is a manufacturing process where molten metal or other materials are poured into a mold cavity and allowed to solidify, forming a specific shape. This traditional method is widely used for producing complex geometries and large components in industries such as automotive, aerospace, and heavy machinery. Casting enables mass production with excellent material properties and surface finish, although it typically involves longer production times and higher tooling costs compared to additive manufacturing.

Definition and Overview of Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a process of creating objects by layering materials based on digital models, allowing for complex geometries and customized designs. Unlike casting, which involves pouring molten material into molds to shape parts, additive manufacturing builds components layer by layer, minimizing material waste and enabling rapid prototyping. This technology supports a wide range of materials including plastics, metals, and composites, making it versatile for industries such as aerospace, automotive, and healthcare.

Key Differences Between Casting and Additive Manufacturing

Casting involves pouring molten material into a mold to create complex parts with high strength but limited geometric flexibility, while additive manufacturing builds objects layer-by-layer from digital models, allowing intricate designs and rapid prototyping. Casting is ideal for mass production with consistent mechanical properties, whereas additive manufacturing excels in customization, reduced material waste, and production of lightweight components. Key differences include process speed, material options, surface finish quality, and design freedom, influencing their application in industries like aerospace, automotive, and medical devices.

Material Compatibility and Selection

Casting offers extensive material compatibility with traditional metals such as aluminum, steel, and iron, making it ideal for large-scale production of complex parts. Additive manufacturing excels in working with advanced materials including titanium alloys, polymers, and composites, enabling customized properties and lightweight designs. Material selection in casting favors high melting point metals for strength, while additive manufacturing allows precise control over material composition and microstructure for tailored performance.

Design Flexibility and Complexity

Casting offers limited design flexibility as it requires molds and tooling, which restricts intricate geometries and design modifications. Additive manufacturing enables complex and highly detailed designs with minimal constraints, allowing for intricate internal structures and customization without the need for specialized tooling. This makes additive manufacturing ideal for producing parts with complex geometries and rapid design iterations.

Production Speed and Efficiency

Casting offers faster production speed for large-volume manufacturing due to established mold processes enabling rapid replication, ideal for high-demand industries like automotive and aerospace. Additive manufacturing excels in efficiency for low-volume, complex, or customized parts by eliminating tooling time and reducing material waste, suitable for prototyping and specialized applications. Production speed in casting depends on mold creation and cooling time, whereas additive manufacturing's efficiency maximizes with design flexibility and on-demand manufacturing capabilities.

Cost Comparison: Casting vs Additive Manufacturing

Casting generally offers lower costs for high-volume production due to economies of scale and established tooling processes, making it ideal for large batch manufacturing. Additive manufacturing incurs higher per-unit costs driven by slower production speeds and material expenses but reduces upfront tooling investment, benefiting low-volume and customized parts. When comparing total cost of ownership, casting is more economical for mass production, while additive manufacturing provides cost efficiency in prototyping and small-scale fabrication.

Typical Applications and Industry Use Cases

Casting remains dominant in automotive, aerospace, and heavy machinery sectors for producing large metal parts with complex geometries and high structural integrity, such as engine blocks and turbine blades. Additive manufacturing excels in aerospace, medical implants, and custom tooling by offering rapid prototyping, lightweight structures, and intricate designs that are difficult to create with traditional methods. Industries leverage casting for mass production of standardized components, while additive manufacturing supports low-volume, high-complexity parts and customized solutions in advanced manufacturing workflows.

Future Trends in Casting and Additive Manufacturing

Future trends in casting emphasize the integration of smart manufacturing technologies such as AI-driven process optimization and advanced simulation tools to enhance precision and reduce defects. Additive manufacturing is rapidly advancing with the development of multi-material printing, increased build speeds, and improved scalability for industrial applications. Both methods are converging through hybrid manufacturing approaches, leveraging the strengths of casting's material properties and additive manufacturing's design flexibility for next-generation production solutions.

Casting Infographic

libterm.com

libterm.com