Pneumatics harness compressed air to power machinery and tools, offering reliable and efficient motion control solutions in various industries. This technology is widely used in manufacturing, automotive, and automation applications due to its simplicity, safety, and ease of maintenance. Discover how understanding pneumatics can enhance your operational efficiency by reading the rest of the article.

Table of Comparison

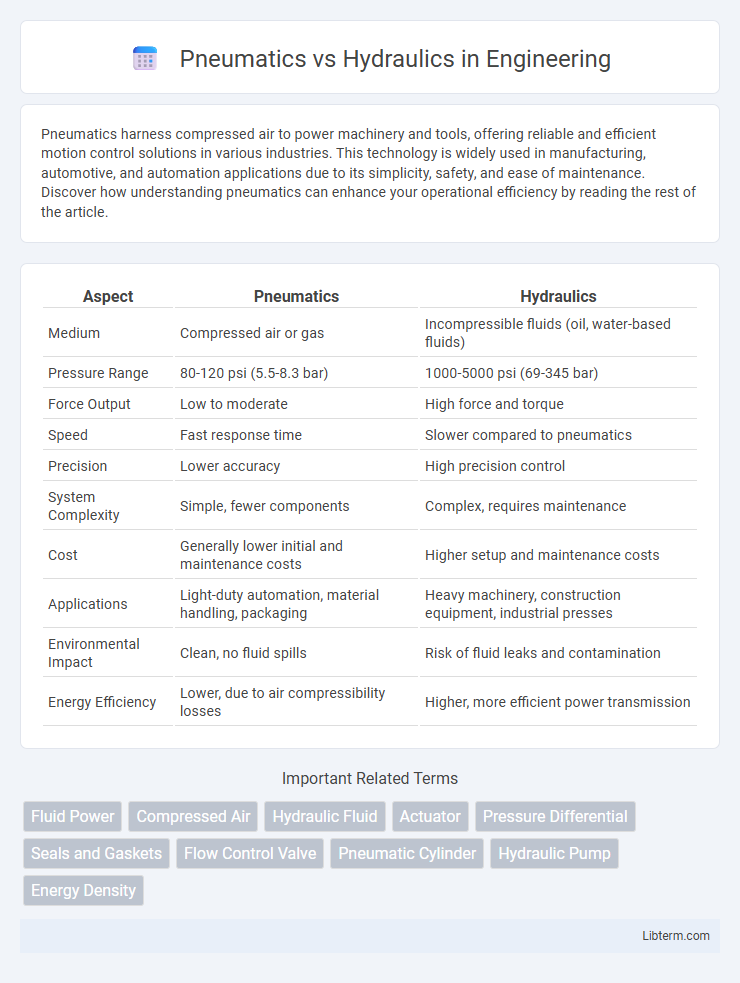

| Aspect | Pneumatics | Hydraulics |

|---|---|---|

| Medium | Compressed air or gas | Incompressible fluids (oil, water-based fluids) |

| Pressure Range | 80-120 psi (5.5-8.3 bar) | 1000-5000 psi (69-345 bar) |

| Force Output | Low to moderate | High force and torque |

| Speed | Fast response time | Slower compared to pneumatics |

| Precision | Lower accuracy | High precision control |

| System Complexity | Simple, fewer components | Complex, requires maintenance |

| Cost | Generally lower initial and maintenance costs | Higher setup and maintenance costs |

| Applications | Light-duty automation, material handling, packaging | Heavy machinery, construction equipment, industrial presses |

| Environmental Impact | Clean, no fluid spills | Risk of fluid leaks and contamination |

| Energy Efficiency | Lower, due to air compressibility losses | Higher, more efficient power transmission |

Introduction to Pneumatics and Hydraulics

Pneumatics utilizes compressed air to power mechanical systems, offering advantages such as rapid movement, cleanliness, and ease of maintenance, making it ideal for applications in automation and manufacturing. Hydraulics employs pressurized fluids, typically oil, to generate high force and precise control, suitable for heavy machinery like construction equipment and industrial presses. Both technologies convert energy into mechanical motion but differ in medium, pressure range, and force output, influencing their application scope and performance characteristics.

Fundamental Principles of Fluid Power

Pneumatics uses compressed air to transmit power, relying on the compressibility of gases and typically operating at pressures up to 150 psi for rapid, lightweight applications. Hydraulics utilizes incompressible liquid fluids, such as oil, enabling higher pressure capabilities often exceeding 3000 psi for precise, heavy-duty force control. Both systems transform fluid power into mechanical energy, but their fundamental difference lies in fluid properties affecting efficiency, force output, and application suitability in various industrial settings.

Key Components in Pneumatic and Hydraulic Systems

Pneumatic systems primarily rely on compressed air, using components such as air compressors, pneumatic cylinders, valves, and air filters to control motion and force. Hydraulic systems utilize incompressible fluids like oil, featuring hydraulic pumps, hydraulic cylinders, reservoirs, and control valves designed to generate high power and precise control. Key distinctions include the medium used--air versus fluid--and the design of actuators and control devices optimized for pressure and fluid dynamics in each system.

Energy Sources: Compressed Air vs Hydraulic Fluids

Pneumatic systems utilize compressed air as their energy source, offering rapid response times and cleaner operation with less risk of leaks, making them ideal for lightweight and low-force applications. Hydraulic systems rely on hydraulic fluids, which provide higher energy density and greater force output, suitable for heavy-duty industrial machinery requiring precise control and sustained power. The choice between compressed air and hydraulic fluids depends on factors such as required power, system complexity, maintenance needs, and environmental considerations.

Efficiency Comparison: Pneumatics vs Hydraulics

Hydraulic systems typically offer higher efficiency than pneumatic systems due to their use of incompressible fluids, which result in less energy loss during power transmission. Pneumatic systems experience greater energy losses because of air compressibility and leakage, leading to lower overall efficiency, especially in continuous heavy-duty applications. For tasks requiring precise control and consistent power output, hydraulics provide superior performance and energy savings compared to pneumatics.

Application Areas and Industry Use Cases

Pneumatics is widely used in applications requiring rapid movement and low force, such as assembly line automation, packaging machines, and robotics in electronics manufacturing. Hydraulics is favored in heavy-duty industrial sectors including construction equipment, aerospace control systems, and automotive manufacturing due to its ability to generate high power and precise control. Both systems are integral to material handling, with pneumatics commonly deployed in food processing and pharmaceuticals, while hydraulics dominate mining and marine operations.

Advantages of Pneumatic Systems

Pneumatic systems offer advantages such as faster operating speeds and greater cleanliness compared to hydraulics, making them ideal for environments requiring contamination control. They provide simpler maintenance due to fewer fluid leaks and use compressed air, which is readily available and safe. Pneumatics also excel in lightweight applications, delivering reliable performance with lower initial costs.

Strengths of Hydraulic Systems

Hydraulic systems excel in generating high power and precise control due to their use of incompressible fluids, enabling effective operation in heavy-duty industrial applications such as construction machinery and manufacturing presses. Their high force density allows compact designs that deliver consistent and smooth motion under load, enhancing system reliability and performance. Furthermore, hydraulic components offer superior overload protection and energy efficiency compared to pneumatic counterparts, making them ideal for tasks requiring strong and durable power transmission.

Factors Affecting System Selection

System selection between pneumatics and hydraulics depends on factors such as required force, speed, and control precision. Pneumatics are preferred for lightweight, high-speed applications with clean operation, while hydraulics are ideal for heavy-duty tasks demanding high force and precise control. Cost, maintenance, fluid leakage risks, and environmental considerations also influence the choice between pneumatic and hydraulic systems.

Future Trends in Fluid Power Technology

Future trends in fluid power technology emphasize the integration of smart sensors and IoT connectivity in pneumatics and hydraulics to enhance system efficiency and predictive maintenance. Advances in energy-efficient components such as electro-hydraulic valves and compressed air energy storage systems are driving sustainability in industrial applications. The adoption of hybrid fluid power systems combining pneumatic and hydraulic elements facilitates improved performance and adaptability in automation and robotics industries.

Pneumatics Infographic

libterm.com

libterm.com