Bolted joints provide a reliable method for fastening components, ensuring strong mechanical connections in various applications such as machinery, construction, and automotive industries. They resist shear, tension, and bending forces while allowing for disassembly and maintenance, making them versatile and cost-efficient. Discover how bolted joint types, installation techniques, and common failure prevention can enhance your project's durability by reading further.

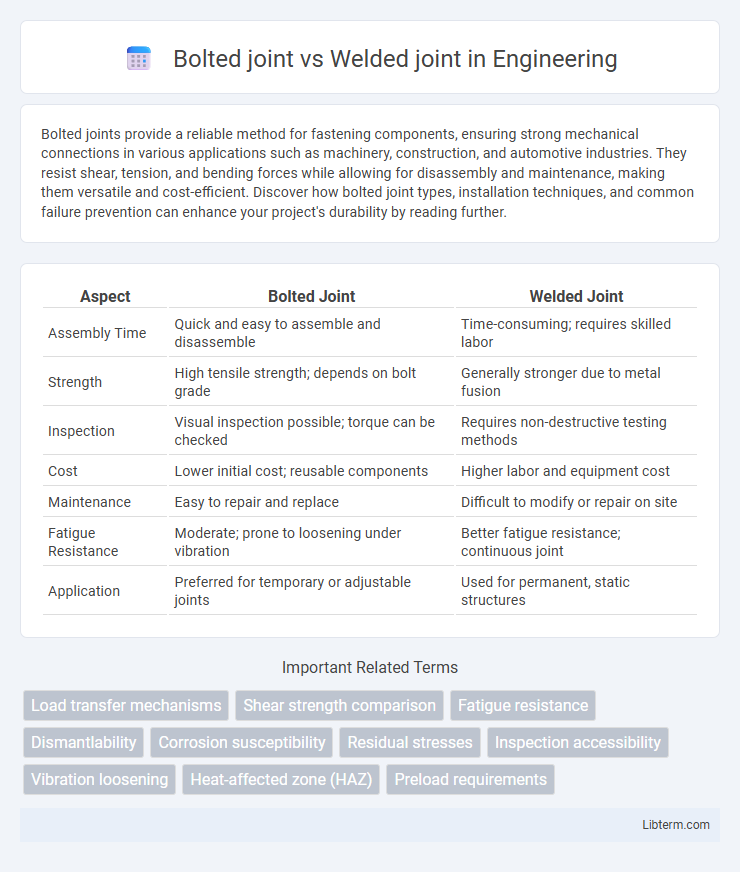

Table of Comparison

| Aspect | Bolted Joint | Welded Joint |

|---|---|---|

| Assembly Time | Quick and easy to assemble and disassemble | Time-consuming; requires skilled labor |

| Strength | High tensile strength; depends on bolt grade | Generally stronger due to metal fusion |

| Inspection | Visual inspection possible; torque can be checked | Requires non-destructive testing methods |

| Cost | Lower initial cost; reusable components | Higher labor and equipment cost |

| Maintenance | Easy to repair and replace | Difficult to modify or repair on site |

| Fatigue Resistance | Moderate; prone to loosening under vibration | Better fatigue resistance; continuous joint |

| Application | Preferred for temporary or adjustable joints | Used for permanent, static structures |

Introduction to Bolted and Welded Joints

Bolted joints use mechanical fasteners such as bolts and nuts to connect components, allowing easy disassembly and maintenance, making them ideal for structures requiring periodic inspection or replacement. Welded joints create a permanent bond by fusing materials at the interface through heat, providing high strength and rigidity commonly used in heavy-duty applications and structural frameworks. Both joining methods are crucial in engineering, with bolted joints offering flexibility and welded joints delivering superior integrity in load-bearing scenarios.

Definition and Components of Bolted Joints

Bolted joints consist of fasteners, such as bolts, nuts, and washers, that clamp components together through mechanical tension, providing a detachable and adjustable connection. Unlike welded joints, which permanently fuse metals by applying heat, bolted joints rely on threaded components and compression to maintain structural integrity. Key components of bolted joints include bolts (with specified grades and diameters), nuts that secure the bolt, washers that distribute load and prevent damage, and the joined materials themselves.

Definition and Processes in Welded Joints

A bolted joint connects components using bolts and nuts, providing a removable mechanical fastening method ideal for ease of assembly and disassembly. Welded joints involve fusing materials together by applying heat, pressure, or both, creating a permanent bond through processes such as arc welding, MIG, TIG, or resistance welding. These welding techniques melt the base metal and filler material, resulting in a strong, continuous joint crucial for structural integrity in manufacturing and construction.

Strength and Load-Bearing Capabilities

Bolted joints provide high tensile strength with the advantage of easy disassembly, making them suitable for structures requiring maintenance and flexibility under dynamic loads. Welded joints offer superior load-bearing capacity in terms of shear and compressive forces due to the continuous metal fusion, resulting in enhanced rigidity and structural integrity. The choice between bolted and welded joints depends on the specific application's strength requirements, load types, and fatigue resistance considerations.

Installation and Assembly Methods

Bolted joints require precise alignment of components with pre-drilled holes and use nuts and bolts for assembly, enabling quick installation and easier disassembly for maintenance or adjustments. Welded joints involve melting and fusing base metals together, demanding skilled labor and specialized equipment, resulting in a permanent and robust connection. Bolted connections offer flexibility during assembly, while welded joints provide superior strength but require more time and expertise to install.

Inspection and Maintenance Considerations

Bolted joints require regular inspection for bolt tension, corrosion, and thread integrity, with maintenance involving retightening or replacement to ensure structural stability. Welded joints demand thorough examination for cracks, porosity, and weld defects using non-destructive testing methods like ultrasonic or radiographic inspection, as repairs often require grinding and rewelding. Proper maintenance of bolted joints is generally easier and faster, while welded joints provide a more permanent connection but involve more complex and time-consuming inspection and repair processes.

Cost Comparison and Economic Factors

Bolted joints typically have lower initial costs due to simpler fabrication and ease of assembly, requiring less specialized labor and equipment compared to welded joints. Welded joints often incur higher upfront expenses related to skilled labor, welding materials, and quality control measures, but they provide stronger, more permanent connections that can reduce maintenance and replacement costs over time. Economic factors such as production volume, structural requirements, and lifecycle maintenance expenses critically influence the cost-effectiveness of bolted versus welded joints in industrial applications.

Durability and Performance in Different Environments

Bolted joints offer superior adaptability in environments subject to vibration and thermal expansion, maintaining integrity through mechanical fastening without the risk of heat-affected zones, which can weaken materials in welded joints. Welded joints provide enhanced strength and a seamless finish ideal for high-pressure or static load conditions but may suffer from corrosion or cracking in harsh, corrosive, or cyclically stressed environments if not properly treated. Durability in diverse climates favors bolted joints for ease of inspection and maintenance, while welded joints demand stringent quality control and protective coatings to withstand environmental degradation.

Applications and Industry Preferences

Bolted joints are widely preferred in automotive, aerospace, and construction industries for their ease of assembly, disassembly, and maintenance, making them ideal for structures requiring periodic inspection or replacement. Welded joints dominate in heavy machinery, shipbuilding, and pipeline industries due to their superior strength, rigidity, and resistance to vibration and shear forces, providing a permanent and robust connection. Industry preference depends on factors like load requirements, environmental conditions, and the need for joint flexibility or permanence.

Conclusion: Choosing Between Bolted and Welded Joints

Choosing between bolted and welded joints depends on factors such as load requirements, environmental conditions, and maintenance needs; bolted joints offer ease of assembly and disassembly with moderate strength, ideal for applications requiring frequent maintenance. Welded joints provide superior strength and rigidity, suitable for permanent structures exposed to high stress and harsh conditions. Evaluating cost, fabrication time, and joint accessibility ensures optimal selection for structural integrity and longevity.

Bolted joint Infographic

libterm.com

libterm.com