A push rod is a critical component in internal combustion engines, transferring motion from the camshaft to the valve lifters and rocker arms to open and close the valves. Its proper function ensures precise timing and efficient engine performance, preventing mechanical failures and maintaining power output. Explore the rest of the article to understand how push rods work and their importance in your engine system.

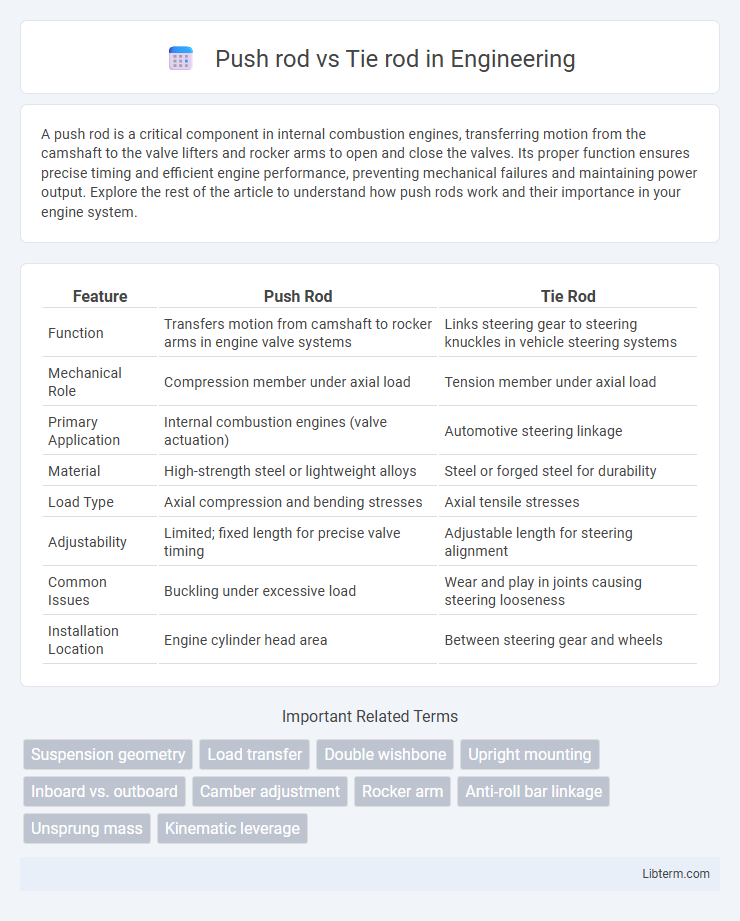

Table of Comparison

| Feature | Push Rod | Tie Rod |

|---|---|---|

| Function | Transfers motion from camshaft to rocker arms in engine valve systems | Links steering gear to steering knuckles in vehicle steering systems |

| Mechanical Role | Compression member under axial load | Tension member under axial load |

| Primary Application | Internal combustion engines (valve actuation) | Automotive steering linkage |

| Material | High-strength steel or lightweight alloys | Steel or forged steel for durability |

| Load Type | Axial compression and bending stresses | Axial tensile stresses |

| Adjustability | Limited; fixed length for precise valve timing | Adjustable length for steering alignment |

| Common Issues | Buckling under excessive load | Wear and play in joints causing steering looseness |

| Installation Location | Engine cylinder head area | Between steering gear and wheels |

Introduction to Push Rods and Tie Rods

Push rods and tie rods are essential components in automotive steering and suspension systems, each serving distinct mechanical functions. Push rods transfer motion and force between components, commonly found in internal combustion engines and suspension linkages to facilitate precise movements. Tie rods connect the steering rack to the wheel hubs, enabling accurate wheel alignment and responsive steering control in vehicles.

Core Functions of Push Rods

Push rods primarily function to transfer motion and force from the camshaft to the valve lifters in internal combustion engines, enabling the precise opening and closing of engine valves. Unlike tie rods, which are used in steering systems to maintain alignment and manage wheel movement, push rods are critical in maintaining valve timing and engine efficiency. Their role ensures optimal engine performance by converting rotational motion into linear motion needed for valve operation.

Core Functions of Tie Rods

Tie rods primarily serve as key components in a vehicle's steering system, connecting the steering rack to the steering knuckle and ensuring precise wheel alignment and responsive handling. They transmit force from the steering center link or rack gear to the steering knuckle, enabling controlled wheel movement and maintaining proper tire contact with the road. Unlike push rods, which are integral to suspension systems and transmit motion to valve components, tie rods focus on steering dynamics and safety by controlling lateral wheel positioning.

Key Differences Between Push Rods and Tie Rods

Push rods transfer motion by pushing or compressing components in engine valvetrains or suspensions, whereas tie rods primarily transmit tensile forces to maintain alignment in steering and suspension systems. Push rods are typically rigid and handle compressive loads, while tie rods are designed to withstand tension and ensure precise control of wheel direction. The material composition and mechanical function differ significantly, with push rods often made from strong metal alloys for durability under compression, and tie rods engineered for flexibility and strength under tension.

Materials and Construction Comparison

Push rods are typically constructed from high-strength steel or aluminum alloys, offering excellent stiffness and durability to withstand compressive forces in suspension systems. Tie rods are commonly made from forged steel or carbon steel, prioritizing tensile strength and resistance to bending under tension during steering linkage operation. The choice of materials reflects their distinct functional roles: push rods emphasize rigidity and lightweight construction, while tie rods focus on robust tensile properties for precise steering control.

Application in Automotive Suspension Systems

Push rods in automotive suspension systems transfer forces from the wheel to the rocker or damper, allowing for precise control in high-performance and racing vehicles with inboard suspension setups. Tie rods serve as critical steering components, connecting the steering rack to the wheels, enabling accurate directional control and alignment in most conventional passenger cars. The choice between push rod and tie rod depends on suspension design goals, with push rods favored for weight distribution and aerodynamic benefits, while tie rods prioritize steering responsiveness and simplicity.

Advantages of Push Rod Suspension

Push rod suspension offers enhanced handling by allowing for lower unsprung mass, leading to improved ride quality and better cornering stability. Its design enables precise suspension tuning and packaging flexibility, which is crucial for high-performance and racing vehicles. This system also facilitates easier maintenance by positioning components away from damaged areas, reducing wear and increasing durability.

Benefits of Tie Rod Mechanisms

Tie rod mechanisms offer precise steering control and enhanced stability by directly connecting the steering gear to the wheel assembly, reducing play and improving responsiveness. Their robust design ensures durability and efficient transmission of force, minimizing wear and maintenance requirements compared to push rod systems. Tie rods provide better alignment adjustment capabilities, leading to improved tire longevity and overall vehicle handling performance.

Maintenance and Durability Factors

Push rods typically require less frequent maintenance due to their robust design and fewer moving components, enhancing overall durability in high-stress environments. Tie rods, while easier to adjust and replace, are more susceptible to wear from exposure to road debris and frequent steering adjustments, necessitating more regular inspections and maintenance. Material quality and proper lubrication significantly influence the lifespan of both push rods and tie rods, with corrosion-resistant coatings extending durability under harsh conditions.

Choosing Between Push Rod and Tie Rod Systems

Choosing between push rod and tie rod systems depends on the vehicle's design, steering response, and maintenance preferences. Push rods offer a more direct and precise steering feel, often used in high-performance and racing cars due to their reduced flex and improved feedback. Tie rods are common in standard passenger cars, valued for their simplicity, ease of replacement, and cost-effectiveness in everyday driving scenarios.

Push rod Infographic

libterm.com

libterm.com