Globe valves are essential components for regulating flow in piping systems, offering precise control through their adjustable disk mechanism. Designed to handle high-pressure applications, they provide reliable shutoff and minimal leakage, enhancing system efficiency. Explore the rest of the article to understand how globe valves can optimize your industrial operations.

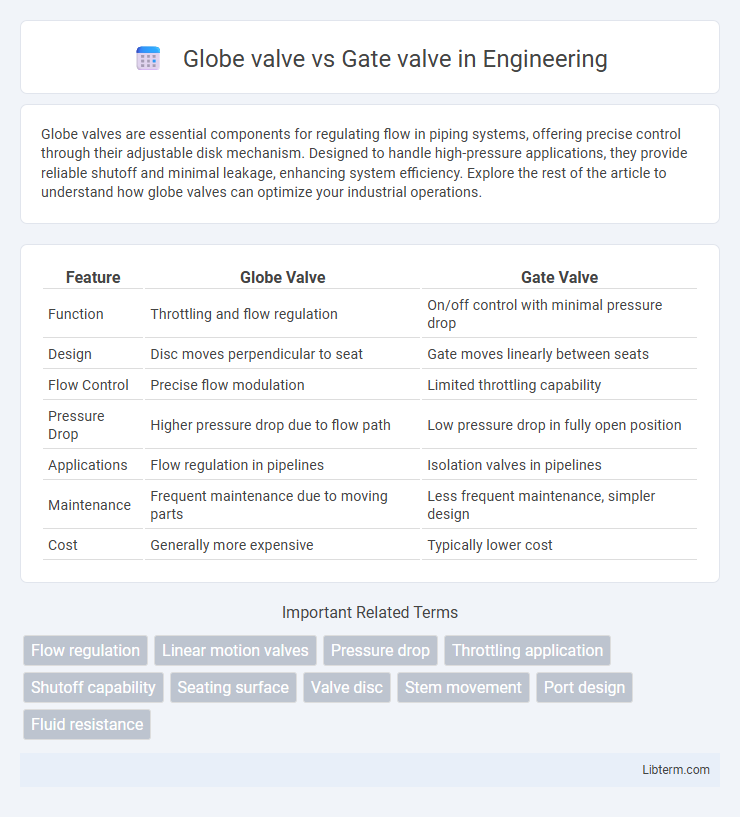

Table of Comparison

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Function | Throttling and flow regulation | On/off control with minimal pressure drop |

| Design | Disc moves perpendicular to seat | Gate moves linearly between seats |

| Flow Control | Precise flow modulation | Limited throttling capability |

| Pressure Drop | Higher pressure drop due to flow path | Low pressure drop in fully open position |

| Applications | Flow regulation in pipelines | Isolation valves in pipelines |

| Maintenance | Frequent maintenance due to moving parts | Less frequent maintenance, simpler design |

| Cost | Generally more expensive | Typically lower cost |

Introduction to Globe Valves and Gate Valves

Globe valves regulate flow by moving a disc or plug perpendicular to the seat, providing precise throttling capabilities in pipelines. Gate valves operate by lifting a gate out of the flow path, allowing for unobstructed fluid passage and are primarily used for on/off control. Both valve types are essential in industrial applications, with globe valves offering superior flow control and gate valves favoring minimal pressure drop when fully open.

Design Differences Between Globe and Gate Valves

Globe valves feature a spherical body shape with a movable disk-type element that regulates flow by moving perpendicular to the seat, allowing precise throttling and flow control. Gate valves have a wedge-shaped gate that moves vertically between two seats to permit or block flow, providing minimal pressure drop when fully open. The design of globe valves results in higher pressure drops compared to gate valves, which are optimized for on/off service with a straight-through flow path.

Working Principles: Globe Valve vs Gate Valve

Globe valves operate using a linear motion where a disc moves perpendicularly to the flow path to regulate fluid flow, allowing precise throttling and shut-off. Gate valves function by lifting a wedge-shaped gate vertically from the flow path, providing minimal resistance when fully open, which is suited for on/off control rather than flow regulation. The distinct working principles of globe and gate valves influence their application, with globe valves offering better flow control and gate valves excelling in straight-through flow and low-pressure loss scenarios.

Flow Control Capabilities

Globe valves offer precise flow control due to their linear motion and adjustable disc, making them ideal for throttling applications and regulating flow rates. Gate valves provide minimal flow resistance when fully open, but their primary function is on/off service rather than fine flow control. The design differences result in globe valves being superior for modulating flow, while gate valves excel in applications requiring tight shutoff.

Pressure Drop Comparison

Globe valves exhibit higher pressure drops due to their tortuous flow path and throttling design, causing more energy loss compared to gate valves. Gate valves offer minimal pressure drop because their straight-through flow design creates less flow resistance when fully open. Selection between these valves depends on balancing the need for precise flow control (globe valve) against pressure efficiency (gate valve).

Applications and Typical Uses

Globe valves are ideal for applications requiring precise flow regulation and throttling, commonly used in cooling water systems, fuel oil systems, and steam lines. Gate valves are typically employed in on/off control applications where minimal pressure drop is essential, such as water supply systems, wastewater treatment, and oil pipelines. Both valves serve critical roles in industrial processes but differ significantly in their operational strengths and usage scenarios.

Durability and Maintenance Requirements

Globe valves offer superior durability in applications involving frequent throttling due to their robust disc and seat design, which withstands wear better than gate valves. Gate valves typically require less maintenance because their simple linear motion causes minimal damage during fully open or closed positions, but they are more prone to leakage if seats wear out. Maintenance costs for globe valves may be higher due to more complex parts and potential need for gasket replacement, while gate valves generally have lower upkeep but shorter lifespan under frequent operation.

Installation and Space Considerations

Globe valves require more space for installation due to their larger body and stem movement, making them less suitable for tight or confined areas compared to gate valves. Gate valves have a more compact design that allows for installation in narrow spaces and flush pipeline setups. Proper alignment and support are crucial for both valves, but gate valves often have simpler installation processes because they do not have the linear stem movement characteristic of globe valves.

Cost Analysis: Globe Valve vs Gate Valve

Globe valves typically have higher initial costs due to their complex design and enhanced flow control capabilities compared to gate valves, which are simpler and more economical. Maintenance expenses for globe valves can be greater because of more moving parts and potential wear in throttling applications, while gate valves generally require less maintenance when used for fully open or closed service. Over the valve's lifecycle, total cost analysis should consider factors like pressure drop, energy consumption, and application suitability, with gate valves favored for minimal flow resistance and globe valves preferred where precise flow regulation is necessary.

Selecting the Right Valve for Your Application

Selecting the right valve between globe and gate types depends on factors such as flow control precision, pressure drop, and maintenance requirements. Globe valves offer superior throttling capabilities and tight shut-off, making them ideal for applications needing flow regulation and frequent adjustments. Gate valves provide minimal pressure loss and are best suited for on/off control in pipeline systems where full flow is required.

Globe valve Infographic

libterm.com

libterm.com